Mitsubishi 380. Manual - part 344

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL

17-44

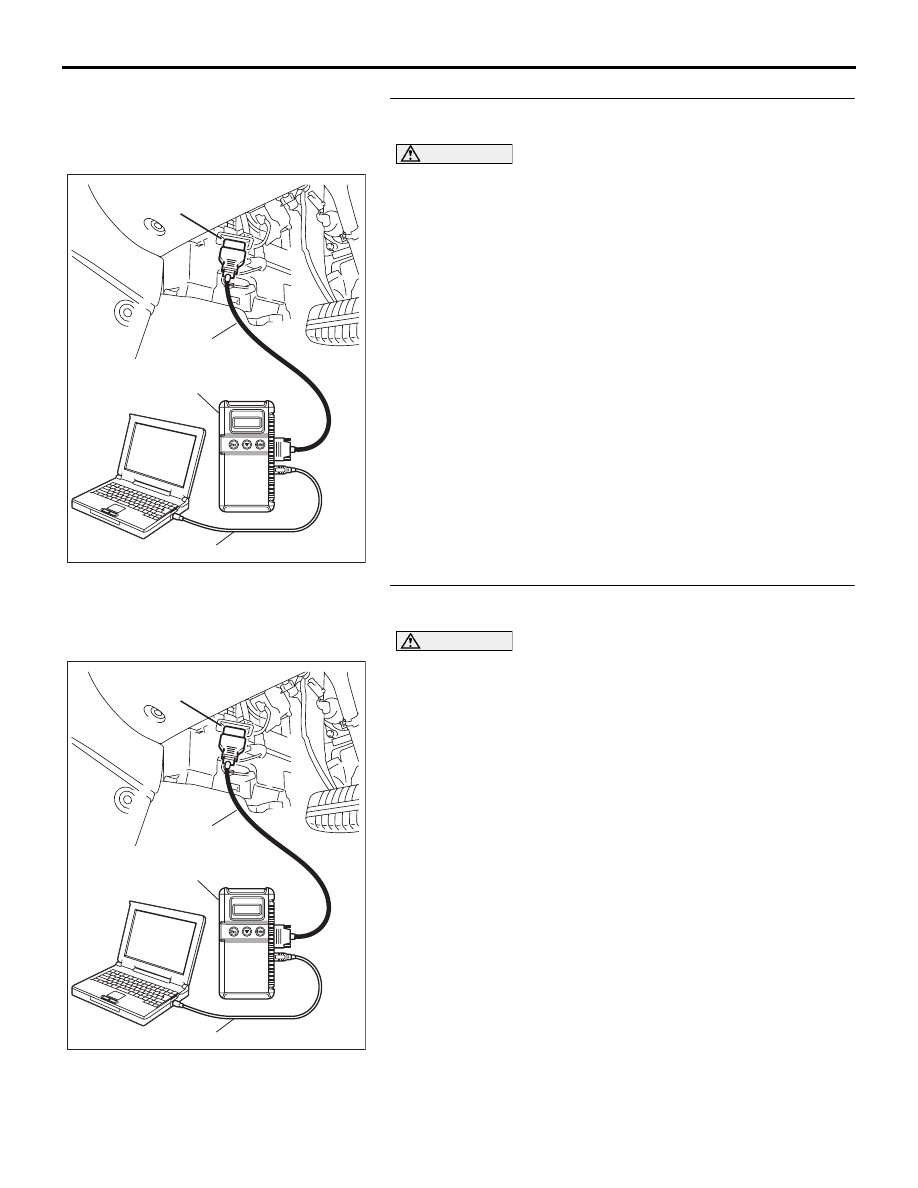

STEP 13. Using Diagnostic Tool MB991958, check data list

item 74: Stoplamp Switch.

CAUTION

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to data reading mode for

auto-cruise control system. (Refer to

• Item 74, Stoplamp Switch.

• When the brake pedal is depressed, the display on

Diagnostic Tool MB991958 should be "ON".

• When the brake pedal is released, the display on

Diagnostic Tool MB991958 should be "OFF".

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is the switch operating properly?

YES : Go to Step 21.

NO : Replace the Engine ECU. [Refer to GROUP 13A,

Engine ECU

STEP 14. Using Diagnostic Tool MB991958, check data list

item 89: Normally closed Brake Switch.

CAUTION

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

(2) Turn the ignition switch to the "ON" position.

(3) Set Diagnostic Tool MB991958 to data reading mode for

auto-cruise control system. (Refer to

• Item 89, Normally closed Brake Switch.

• When the brake pedal is depressed, the display on

Diagnostic Tool MB991958 should be "ON".

• When the brake pedal is released, the display on

Diagnostic Tool MB991958 should be "OFF".

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is the switch operating properly?

YES : Go to Step 21.

NO : Go to Step 15.

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827