Mitsubishi 380. Manual - part 328

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)

13C-32

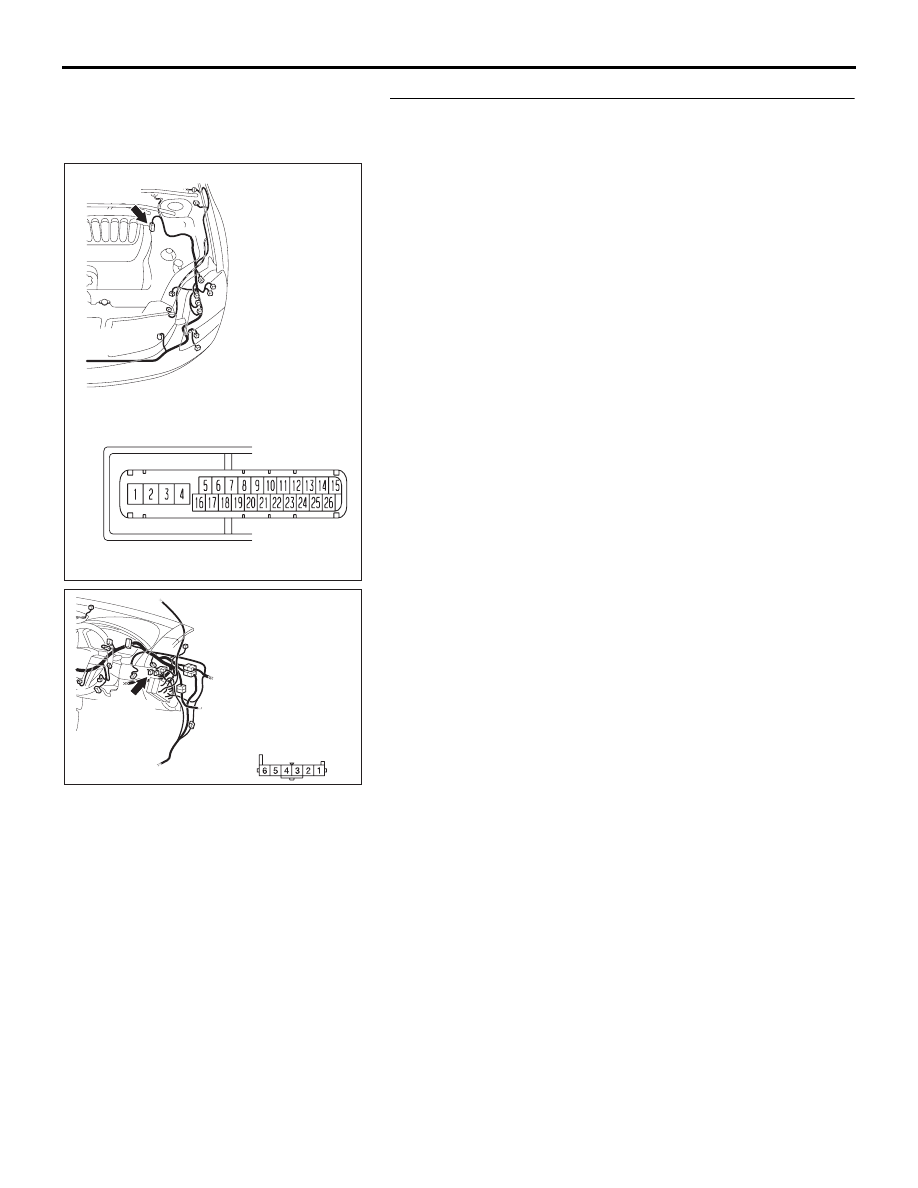

STEP 4. Check the harness wire between ABS/TCL-ECU

connector A-02 terminal 21 and TCL switch connector

C-131 terminal 1 for damage.

Q: Are there harness wires in good condition?

YES : Go to Step 5.

NO : Repair the damaged harness wire. Then go to Step 7.

16DB402A

A-02 (GR)

CONNECTOR: A-02

A-02 HARNESS CONNECTOR:

35DB116A

CONNECTOR: C-131

C-131(GR)

C-131 HARNESS

CONNECTOR:

COMPONENT SIDE