Mitsubishi 380. Manual - part 292

GENERAL DESCRIPTION

BASIC BRAKE SYSTEM

35A-2

GENERAL DESCRIPTION

M1351000100440

The brake system has been designed to give greater

reliability and durability and to provide excellent brak-

ing performance.

FEATURES

.

Improved braking performance

1. An 8+9 inch tandem brake booster provides suffi-

cient braking force in sudden braking range.

2. 296mm front ventilated disc brakes provide sta-

ble braking force and improved braking feel.

3. 303mm rear ventillated disc brakes are used.

.

Improved stability

1. A 4-wheel anti-lock braking system (4ABS) pre-

vents slipping caused by the vehicle wheels lock-

ing up, in order to maintain a stable vehicle

posture and steering performance.

2. An electronic brake-force distribution (EBD)

makes it possible to maintain the maximum

amount of braking force even when the vehicle's

load is unevenly distributed.

3. Front- and rear-wheel X-type brake line layout

are used.

4. Ventilated discs brakes improve anti-fading per-

formance.

.

Improved serviceability

1. A diagnosis function for the ABS system makes

inspection easier.

2. An outer disc separated hub and rotor make

removal and installation easier.

3. The master cylinder reservoir is utilised for both

brake and clutch fluid on manual transmission

vehicles.

4. The master cylinder filter is coloured black for

improved viewing.

5. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

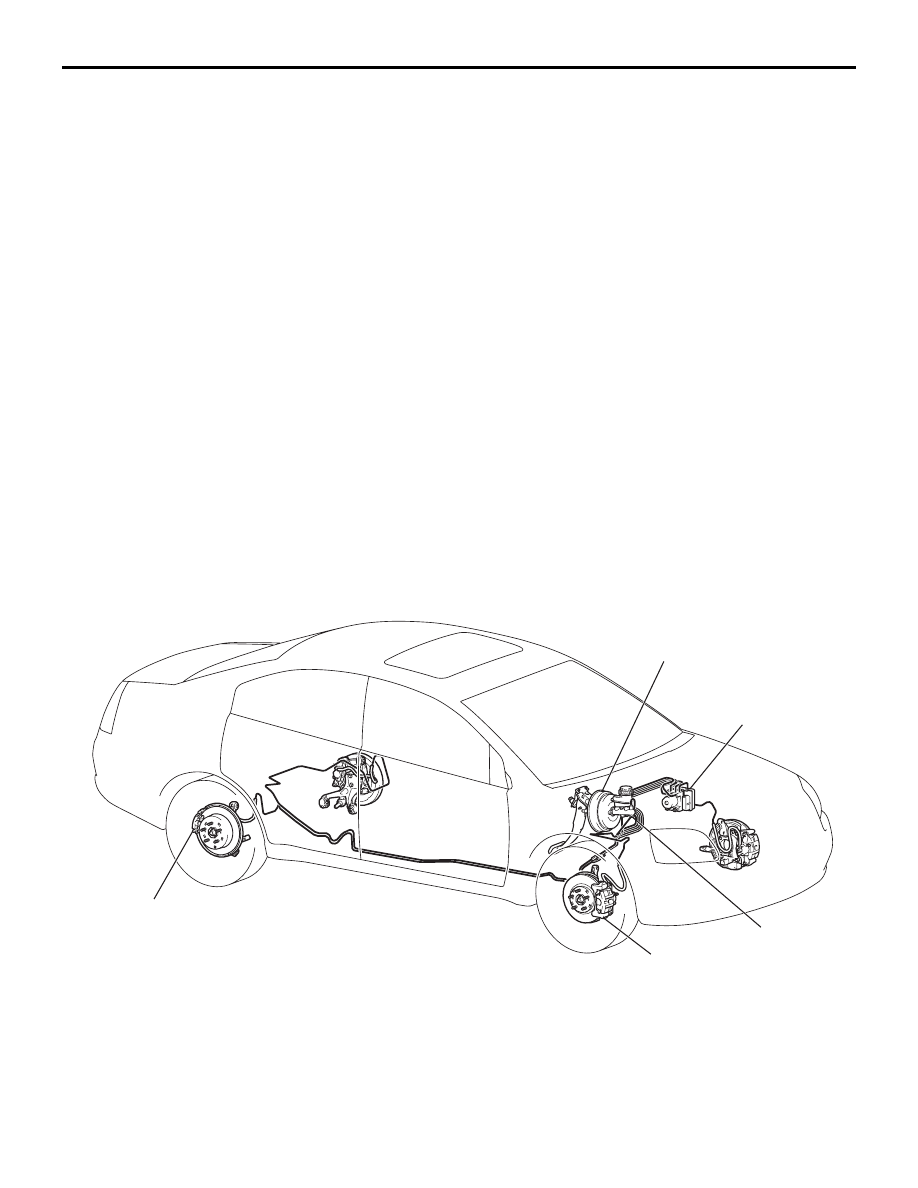

CONSTRUCTION DIAGRAM

BRAKE BOOSTER

HYDRAULIC UNIT

(INTEGRATED WITH

THE ABS-ECU)

MASTER CYLINDER

FRONT DISC BRAKE

REAR DISC BRAKE

<VEHICLE WITH ABS>