Mitsubishi 380. Manual - part 217

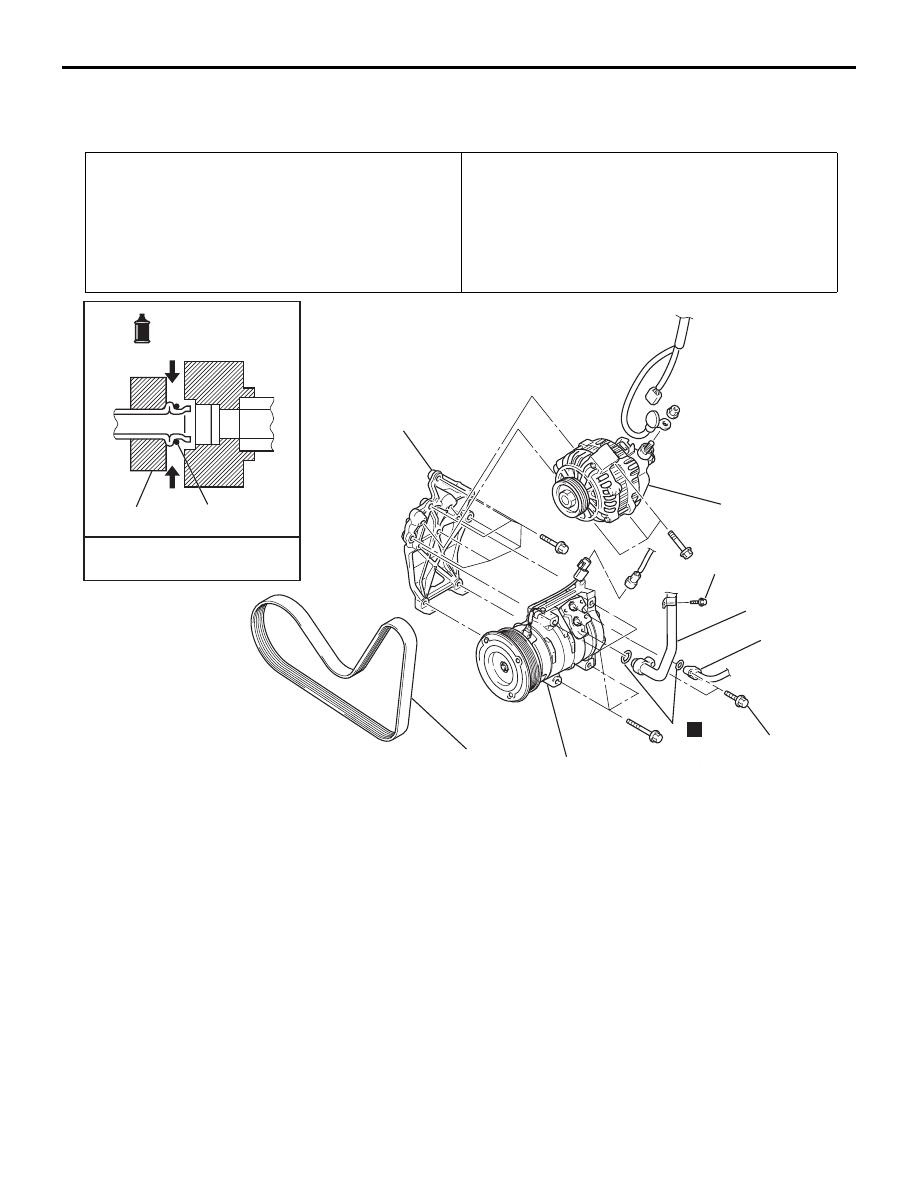

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION

55-164

COMPRESSOR ASSEMBLY AND DRIVE BELT

REMOVAL AND INSTALLATION

M1552004100289

Pre-removal Operation

• Refrigerant Discharging (Refer to

• Front Bumper Under Cover (Refer to GROUP 51, FRONT

• Front Under Cover RH (Refer to GROUP 51, UNDER

).

Post-installation Operation

• Drive Belt Tension Adjustment (Refer to GROUP 00,

Maintenance Service

− Drive Belt

• Refrigerant Charging (Refer to

).

• Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPER

• Front Under Cover RH (Refer to GROUP 51, UNDER

).

25DB139A

N

1

2

3

4

5

6

1, 2

3

A/C compressor oil:

ND Oil 8

-Pipe coupling

7

25 ± 4 N·m

18 ± 3 fi-lb

<3.8 L ENGINE>

12 ± 2 N·m

102 ± 22 in-lb

REMOVAL STEPS

<<A>>

>>A<<

1.

FLEXIBLE SUCTION HOSE

CONNECTION

<<A>>

2.

FLEXIBLE DISCHARGE HOSE

CONNECTION

3.

O-RING

4.

DRIVE BELT

<<B>>

>>B<<

5.

A/C COMPRESSOR

6.

ALTERNATOR

7.

A/C COMPRESSOR BRACKET

REMOVAL STEPS (Continued)