Mitsubishi 380. Manual - part 212

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION

55-144

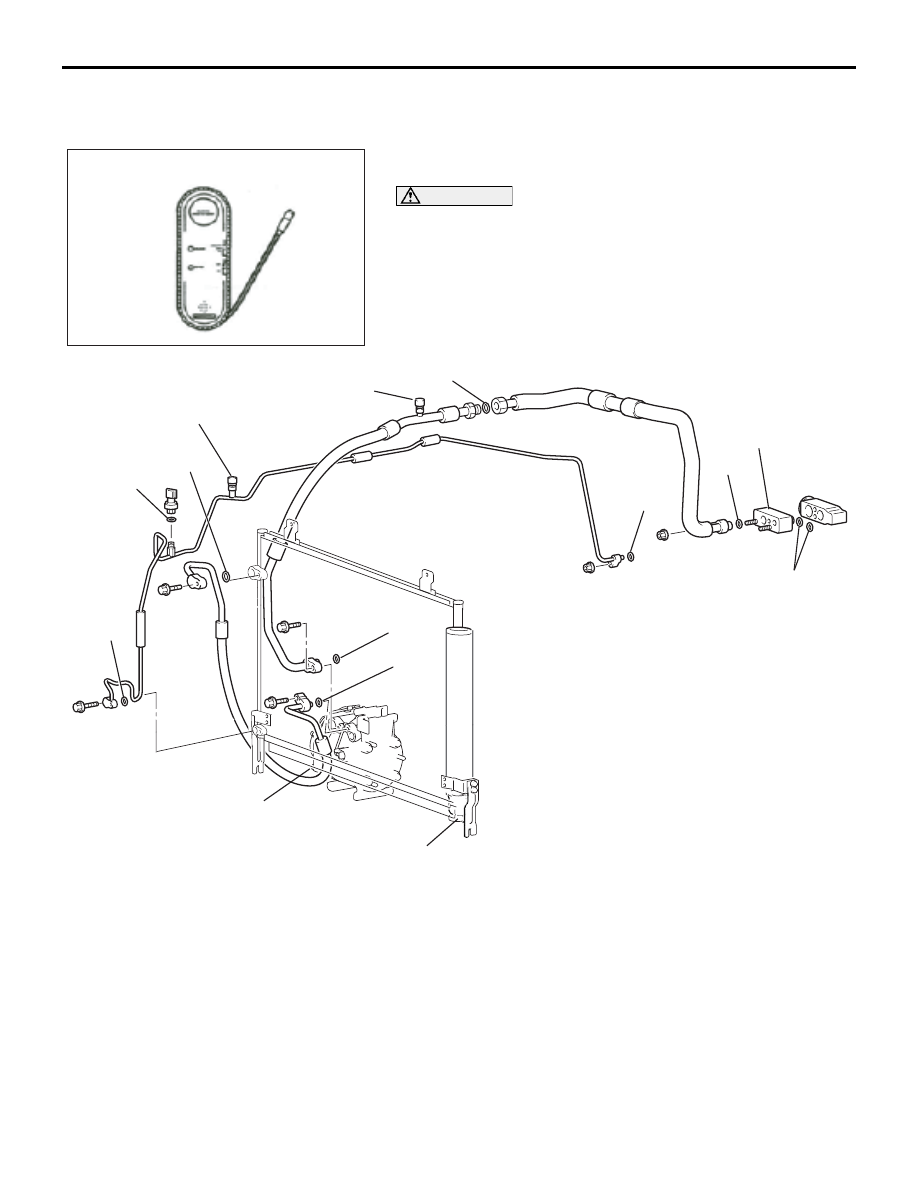

REFRIGERANT LEAK INSPECTION PROCEDURE

M1552001500299

LEAK INSPECTION

1. Check for leakage using Special Tool at the following loca-

tions.

CAUTION

Good ventilation is necessary during the leak inspection. If

the surrounding air is contaminated with refrigerant gas,

the inspection readings will not be accurate.

25DB164A

ELECTRONIC LEAK DETECTOR

25DB163A

1

10

8

3

2

9

12

6

4

5

11

9

7

13

LEAK CHECK LOCATION

1.

SUCTION HOSE TO TX VALVE

2.

LIQUID TUBE TO TX VALVE

3.

SUCTION HOSE JOINT

4.

LOW PRESSURE SERVICE

VALVE

5.

HIGH PRESSURE SERVICE

VALVE

6.

CONDENSER-DISCHARGE

HOSE JOINT

7.

PRESSURE SENSOR

8.

CONDENSER-LIQUID TUBE

JOINT

9.

COMPRESSOR-SUCTION HOSE

JOINT

10. COMPRESSOR-DISCHARGE

HOSE JOINT

11. UNDER COMPRESSOR CLUTCH

12. AROUND MODULATOR CAP

13. TX VALVE TO EVAPORATOR

JOINT

LEAK CHECK LOCATION