Mitsubishi 380. Manual - part 17

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)

54B-65

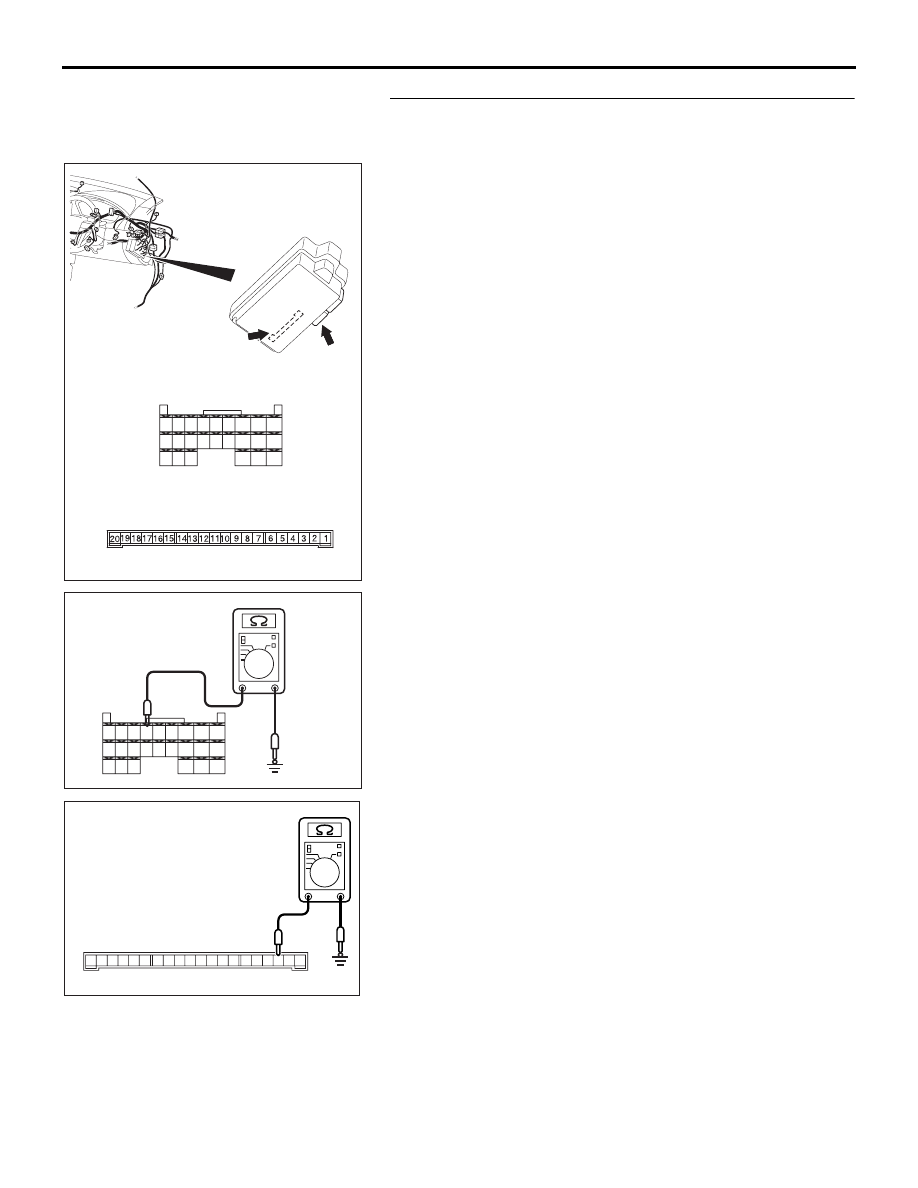

STEP 4. Check the ground circuit to the ETACS-ECU.

Measure the resistance at ETACS-ECU connectors C-218

and C-219.

(1) Disconnect ETACS-ECU connectors C-218 and C-219, and

measure the resistance available at the junction block side

of the connector.

(2) Measure the resistance value between ETACS-ECU

connector C-218 terminal 50 and ground.

• The resistance should be 2 ohms or less.

Measure the resistance value between ETACS-ECU

connector C-219 terminal 3 and ground.

• The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 6.

NO : Go to Step 5.

54DB045A

CONNECTORS: C-218, C-219

JUNCTION BLOCK

(REAR VIEW)

C-219

C-218 (GR)

HARNESS SIDE

C-218

C-219

JUNCTION BLOCK SIDE

45

46

48 47

49

50

59

51

60

52

53

62

65

61

54

63

56

68

64

67 66

57

58

55

54DB046A

CONNECTOR C-218

(HARNESS SIDE)

45

46

48 47

49

50

59

51

60

52

53

62

65

61

54

63

56

68

64

67 66

57

58

55

201918 171615 1413 1211 10 9 8 7 6 5 4 3 2 1

AC209857AB

CONNECTOR C-219

(JUNCTION BLOCK SIDE)