Mitsubishi Grandis. Manual - part 915

ON-VEHICLE SERVICE

ANTI-SKID BRAKING SYSTEM (ABS)

35B-75

RESISTANCE AND CONTINUITY

BETWEEN HARNESS-SIDE CONNECTOR

TERMINALS

1. Turn the ignition switch to the "LOCK" (OFF)

position and disconnect the ABS-ECU connectors

before checking resistance and continuity.

2. Check the resistance and continuity between the

terminals indicated in the table below.

3. The terminal layout is shown in the illustration.

ON-VEHICLE SERVICE

HYDRAULIC UNIT CHECK

M1352001700675

CAUTION

• The roller of the braking force tester and the

tyre should be dry during testing.

• When testing the front brakes, apply the

parking brake. When testing the rear brakes,

stop the front wheels with chocks.

1. Jack up the vehicle. Then support the vehicle with

rigid racks at the specified jack-up points or place

the front or rear wheels on the rollers of the

braking force tester.

2. Release the parking brake, and feel the drag force

(drag torque) on each road wheel. When using

the braking force tester, take a reading of the

brake drag force.

CAUTION

To prevent damage to MUT-III, always turn the

ignition switch to the "LOOK" (OFF) position

before connecting or disconnecting the MUT-III.

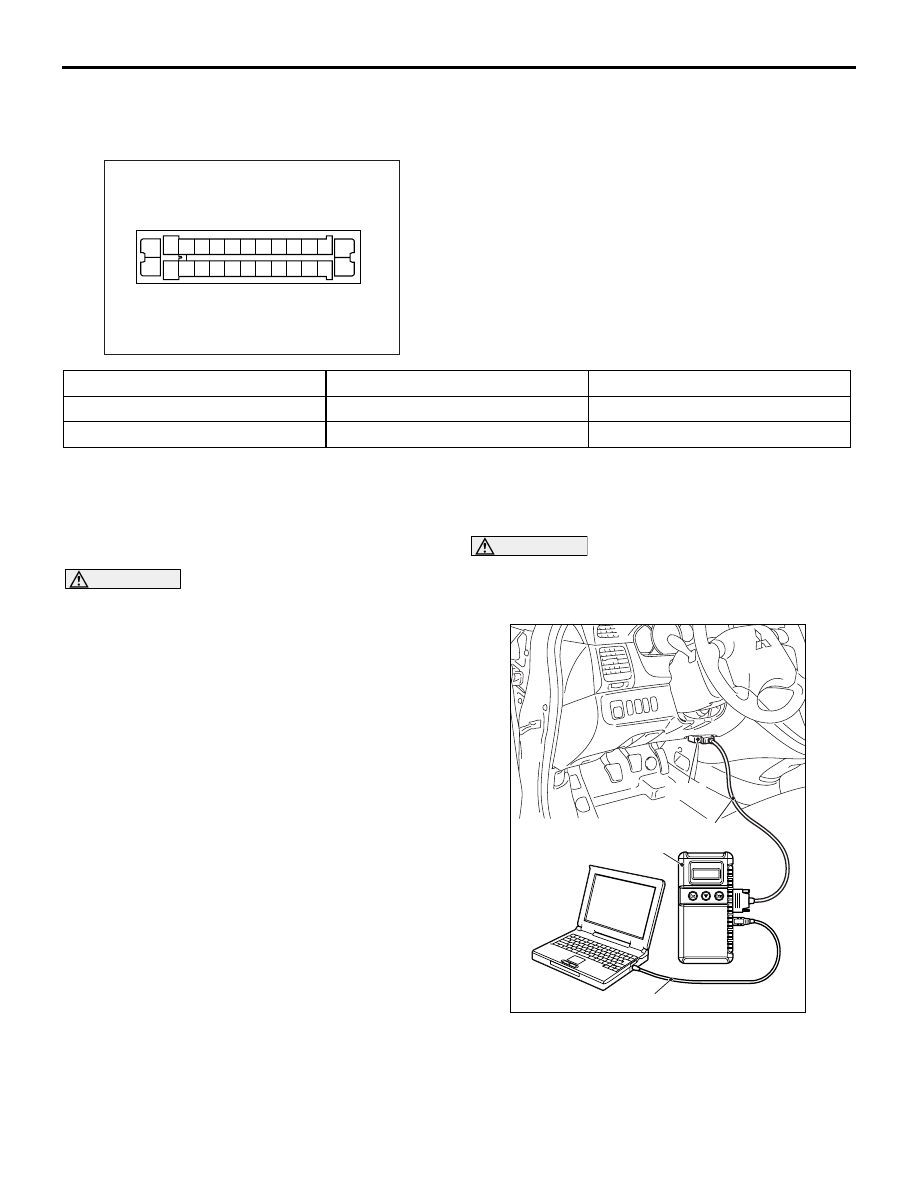

3. Turn the ignition switch to the "LOCK" (OFF)

position and set the MUT-III as shown in the

illustration.

4. After checking that the shift lever is in neutral,

start the engine.

AC313001

1

3

4

5

6

7

8

9

10

11

2

13 12

16

17

18

19

20

21

22

23

24

15

25

14

26

ABS-ECU terminal No.

Signal

Normal condition

13

− body earth

Earth

Less than 2

Ω

26

− body earth

Earth

Less than 2

Ω

AC302297

AC310120

AB

MB991827

16-pin

MB991910

MB991824