Mitsubishi Grandis. Manual - part 885

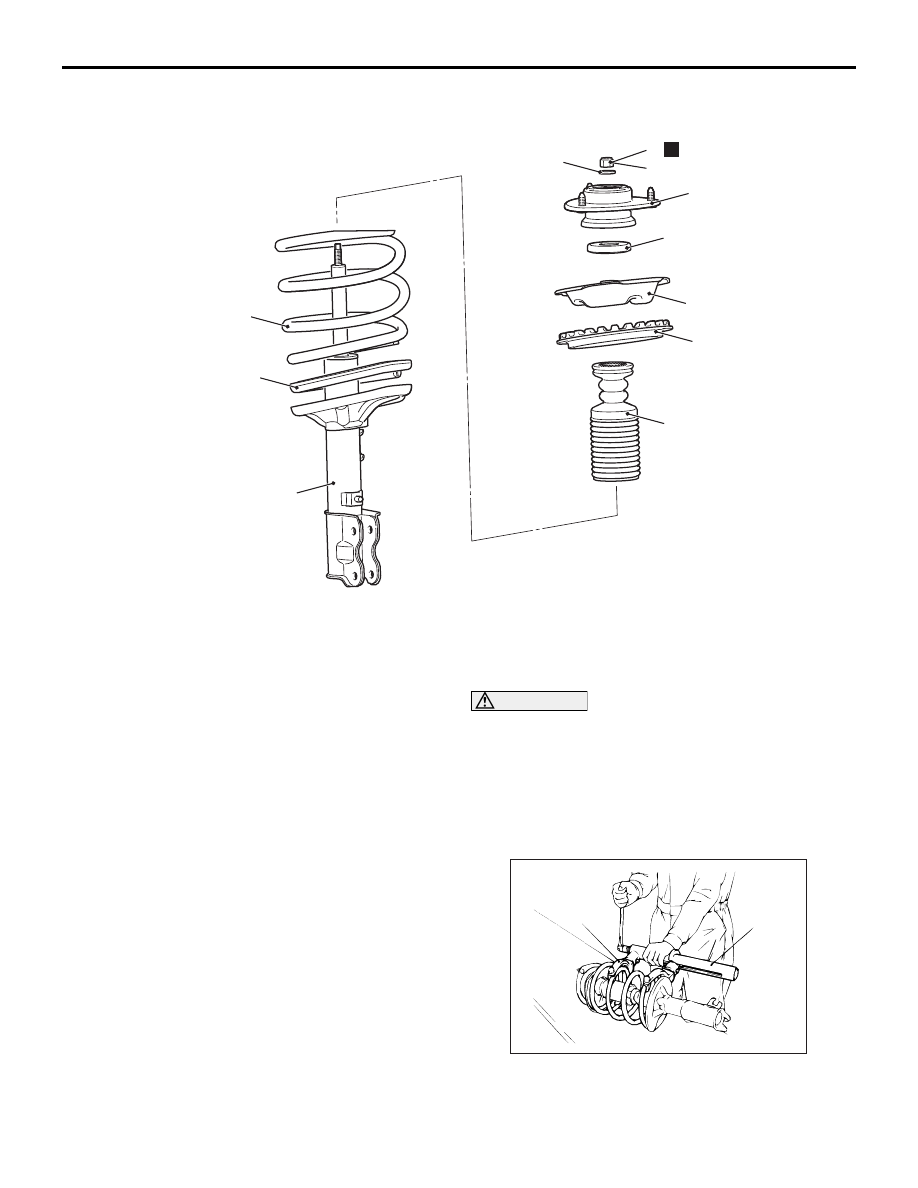

STRUT ASSEMBLY

FRONT SUSPENSION

33-7

DISASSEMBLY AND REASSEMBLY

M1332001300448

DISASSEMBLY SERVICE POINTS

<<A>> STRUT NUT (SELF-LOCKING NUT)

REMOVAL

CAUTION

• Install special tool arm set (MB991238) evenly,

and so that the maximum length will be

attained within the installation range.

• Do not use an impact wrench to tighten the

bolt of special tool spring compressor body

(MB991237), otherwise the special tool will

break.

1. Use following special tools to compress the coil

spring.

• Arm set (MB991795)

• Spring compressor (MB991237)

AC301981AC

75 ± 5 N·m

8

7

10

9

1

2

3

4

5

N

6

Disassembly steps

<<A>> >>C<<

1.

Strut nut (self-locking nut)

2.

Strut washer

3.

Strut insulator assembly

>>B<<

4.

Strut bearing

5.

Spring upper seat

6.

Spring upper pad

>>A<<

7.

Coil spring

8.

Spring lower pad

9.

Strut damper

<<B>>

10. Strut assembly

AC001085 AB

MB991238

MB991237