Mitsubishi Grandis. Manual - part 866

ON-VEHICLE SERVICE

AUTOMATIC TRANSMISSION (FF)

23A-131

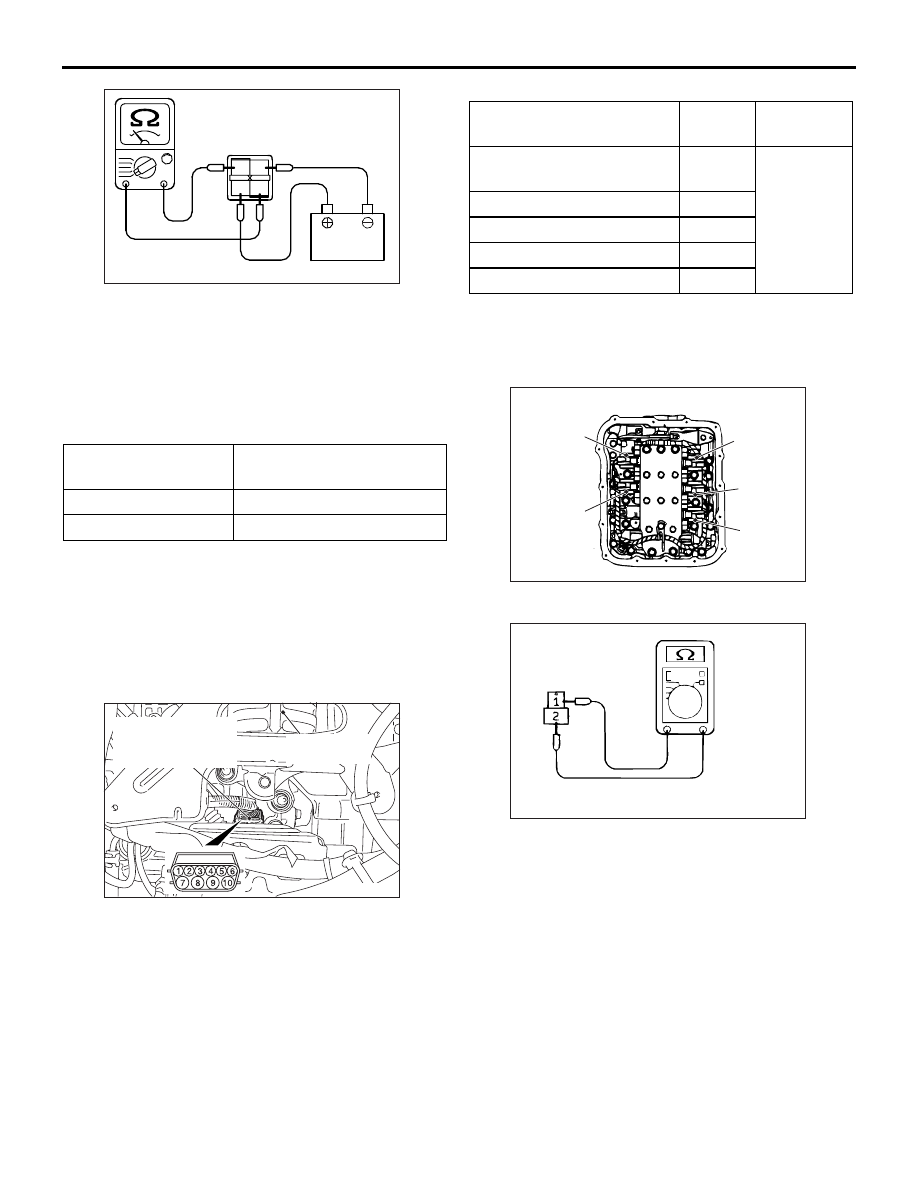

2. Use the jumper leads to connect A/T control relay

terminal 2 to the negative battery terminal and

terminal 3 to the positive battery terminal.

3. Check the continuity between A/T control relay

connector terminals 1 and 4 while alternately

connecting and disconnecting the jumper leads

from the battery terminals.

4. If there is a malfunction, replace the A/T control

relay.

A/T CONTROL SOLENOID VALVE

ASSEMBLY CHECK

M1231009400320

1. Use the MUT-III to measure the ATF temperature

and check that the ATF temperature is 20

°C.

2. Disconnect the A/T control solenoid valve

assembly connector.

3. Measure the resistance between the solenoid

valve terminals.

4. Check that the measured values are within the

standard values at items 1 and 3.

Standard value:

5. If within the standard value, check the power

supply and the earth circuits.

6. If not within the standard value, drain the ATF and

remove the valve body cover.

7. Disconnect the solenoid valve connectors.

8. Measure the resistance between terminals 1 and

2 at each solenoid valve side.

Standard value: 2.7

− 3.4 Ω (A/T fluid

temperature 20

°C)

9. If not within the standard value, replace the

solenoid valve.

10.If within the standard value, check the harness

wire between A/T control solenoid valve assembly

connector and each solenoid valve connector. If a

problem is not found at the steps above, check

the solenoid valve O-rings and replace if

necessary.

A/T FLUID TEMPERATURE SENSOR

CHECK

M1231004500300

1. Drain the ATF and remove the valve body cover.

Jumper leads

Continuity between

terminals 1 and 4

Connected

Less than 2

Ω

Disconnected

Open circuit

AC100115

1 2

3 4

AQ

AC303628AE

Transmission

mount

A/T control

solenoid valve

assembly connector

Name

Terminal

No.

Resistance

value

Damper clutch control

solenoid valve

7

− 10

2.7

− 3.4 Ω

(A/T fluid

temperatur

e 20

°C)

Low-reverse solenoid valve 6

− 10

Second solenoid valve

4

− 9

Underdrive solenoid valve

3

− 9

Overdrive solenoid valve

5

− 9

AC002219

OD

solenoid

valve

LR

solenoid

valve

UD

solenoid

valve

2ND

solenoid

valve

DCC

solenoid

valve

CO

AC002289