Mitsubishi Grandis. Manual - part 690

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-11

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOW

M1131150000999

Refer to

, GROUP 00

− How to Use

Troubleshooting/Inspection Service Points.

DIAGNOSIS FUNCTION

M1131155500609

ENGINE WARNING LAMP (CHECK

ENGINE LAMP)

If an abnormality occurs in any of the following items

related to the Multipoint Fuel Injection (MPI) system,

the engine warning lamp will illuminate.

If the lamp remains illuminated or if the lamp

illuminates while the engine is running, check the

diagnosis code output.

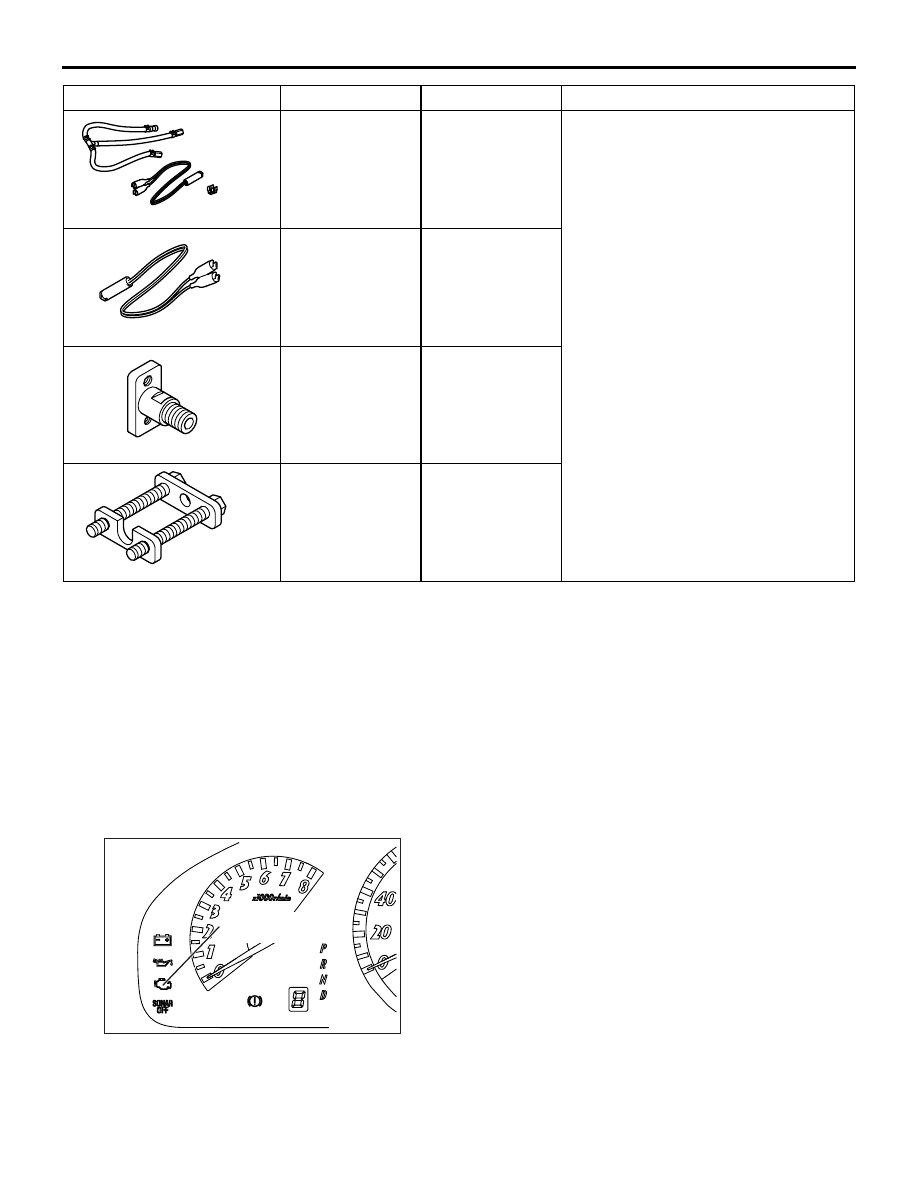

MD998706

Injector test set

Checking the spray condition of

injectors

MB991607

Injector test

harness

MD998741

Injector test

adaptor

MB991976

Injector test

holder assembly

Tool

Number

Name

Use

MD998706

MB991607

MD998741

MB991976

AK305640

Engine warning lamp

(check engine lamp)

AB