Mitsubishi Grandis. Manual - part 664

OIL PAN AND OIL PUMP

ENGINE OVERHAUL

11B-51

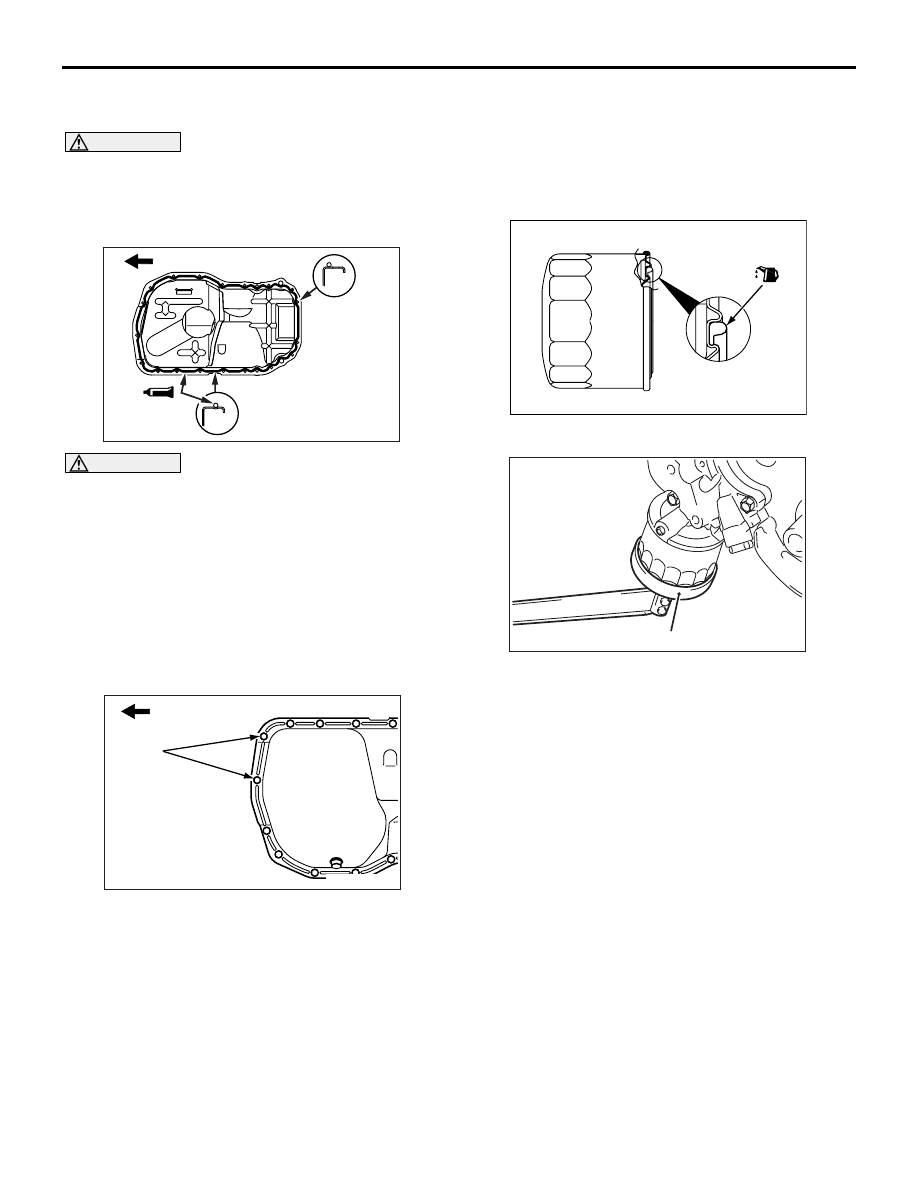

>>K<< OIL PAN INSTALLATION

CAUTION

Do not apply FIPG over remaining old FIPG.

Doing so could result in oil leakage.

1. Thoroughly remove old FIPG from the gasket

surfaces of the cylinder block and oil pan.

CAUTION

Too much FIPG will squeeze out, blocking

coolant or oil passages, while too thin a bead

could result in leakage.

2. Apply a 4 mm diameter bead of FIPG to the flange

surface all around the oil pan.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

NOTE: In the grooved areas on the oil pan flange,

apply FIPG bead along the center of the groove.

3. Install the shorter bolts in the locations indicated

in the drawing.

>>L<< OIL FILTER INSTALLATION

1. Clean the installation surface of the filter bracket.

2. Apply engine oil to the o-ring of the oil filter.

3. Using general service tool, Install the oil filter to

the bracket and tighten it to the specified torque.

Tightening torque

Part number MD356000 filter: 14

± 2 N⋅m

Other Mitsubishi Genuine filter: 17

± 3 N⋅m

4. If a torque wrench cannot be used use the

following procedure:

(1) Screw in the oil filter until its o-ring contacts

the oil filter bracket.

(2) Tighten the oil filter as follows:

Mitsubishi Genuine filter: 3/4 turn

AK202694

Timing belt side

Bolt hole

area

Grooved

area

AB

AK202693

Timing belt side

M6 × 8

AD

AK301069AD

AK300186

General service tool

AD