Mitsubishi Grandis. Manual - part 634

ON-VEHICLE SERVICE

ENGINE MECHANICAL

11A-13

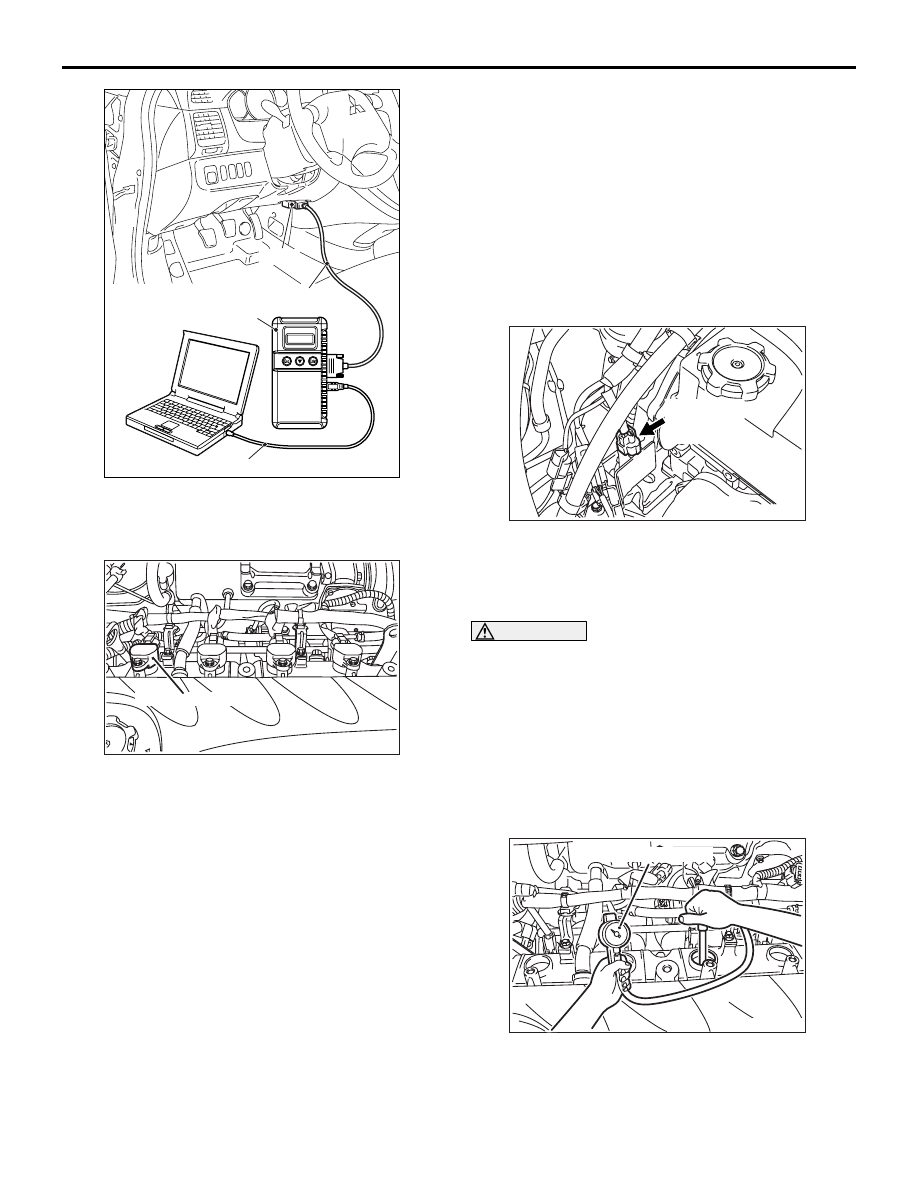

2. Turn the ignition switch to the "LOCK" (OFF)

position and then connect the MUT-III to the

diagnosis connector.

3. Set the timing light to the power supply line

(terminal No.1) of the ignition coil No.1.

NOTE: The power supply line is looped and also

longer than the other ones.

4. Start the engine and let it run at idle.

5. Check that ignition timing is at the standard value.

Standard value: approximately 10

° BTDC

6. Run the engine at 2,500 r/min for 2 minutes.

7. Set the CO, HC tester.

8. Check the CO contents and the HC contents at

idle.

Standard value

CO contents: 0.5 % or less

HC contents: 100 ppm or less

9. If there is a deviation from the standard value,

inspect the MPI system (Refer to

GROUP 13A

− Troubleshooting − Inspection

Chart for Diagnosis Code).

10.Turn the ignition switch to the "LOCK" (OFF)

position and then remove the MUT-III.

COMPRESSION PRESSURE CHECK

M1111002600722

1. Before inspection, set the vehicle to the

pre-inspection condition.

2. Remove all of the ignition coils and spark plugs.

3. Disconnect the crank angle sensor connector.

NOTE: Doing this will prevent the

engine-ECU<M/T> or engine-A/T-ECU<A/T> from

carrying out ignition and fuel injection.

WARNING

Keep away from the spark plug hole when

cranking. If compression is measured with

water, oil, fuel, etc., that has come from

cracks inside the cylinder, these materials

will become heated and will gush out from

the spark plug hole, which is dangerous.

4. Cover the spark plug hole with a shop towel etc.,

and after the engine has been cranked, check that

no foreign material is adhering to the shop towel.

5. Set compression gauge to one of the spark plug

holes.

6. Crank the engine with the throttle valve fully open

and measure the compression pressure.

AC302297

AC310120

AB

MB991827

16-pin

MB991910

MB991824

AK305596AB

No. 1 Ignition coil

AK303421AB

Crank angle

sensor

connector

AK204360

Compression gauge

AE