Mitsubishi Grandis. Manual - part 616

DIAGNOSIS

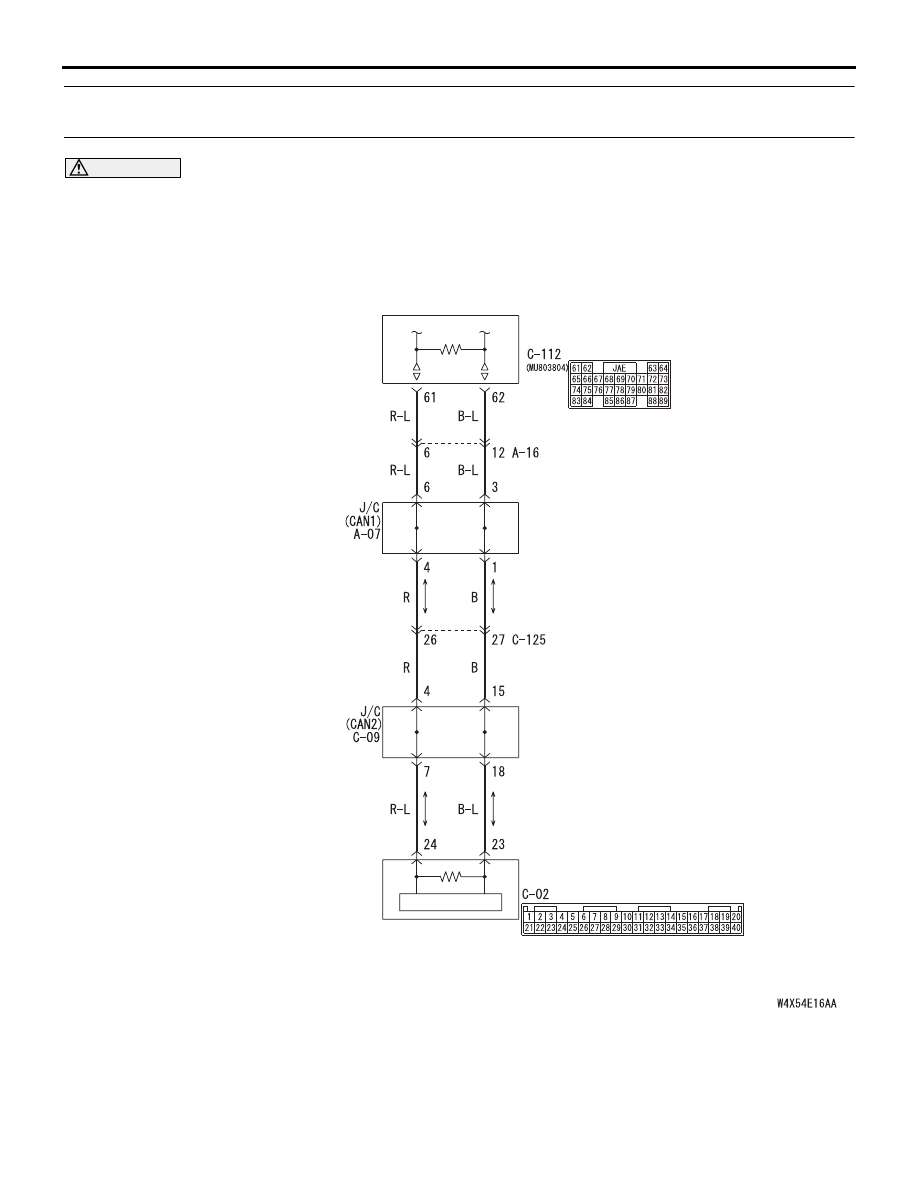

CONTROLLER AREA NETWORK (CAN)

54D-562

Diagnostic Item 23: Diagnose the lines from the main bus line to the engine-ECU <M/T> or

engine-A/T-ECU <A/T>.

CAUTION

When servicing a CAN bus line, earth yourself by

touching a metal object such as an unpainted

water pipe. If you fail to do, a component

connected to the CAN bus line may be broken.

TROUBLE JUDGMENT

If the MUT-III cannot receive any signal from the

engine-ECU <M/T> or engine-A/T-ECU <A/T>, CAN

bus line connector(s) are broken or an open circuit

has occurred.

COMMENTS ON TROUBLE SYMPTOM

Connector(s), wiring harness in the CAN bus lines,

the engine-ECU <M/T> or engine-A/T-ECU <A/T>

may be defective.

ENGINE-ECU<M/T>

ENGINE·A/T-ECU<A/T>

COMBINATION

METER

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet