Mitsubishi Grandis. Manual - part 394

FRONT AXLE HUB ASSEMBLY

FRONT AXLE

26-8

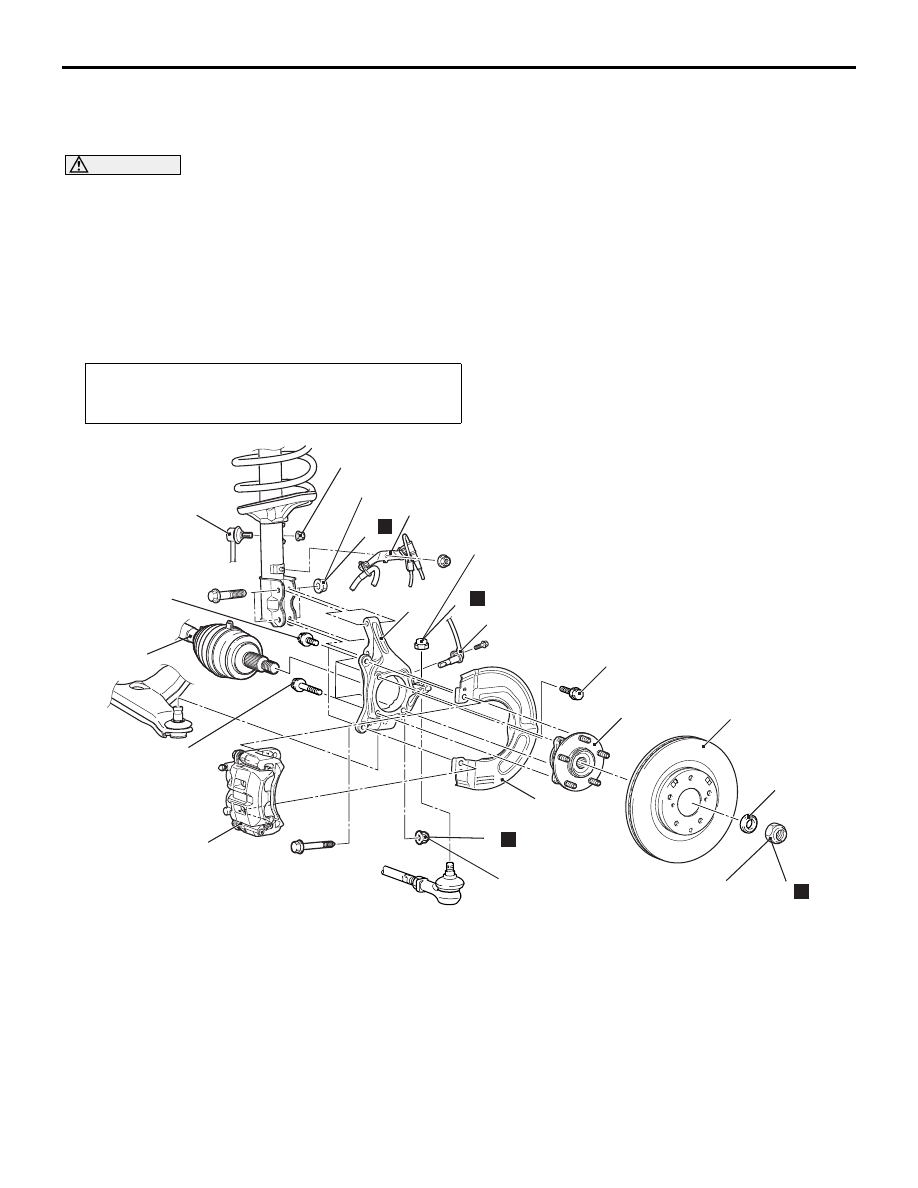

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATION

M1261001700450

CAUTION

• Do not disassemble the front wheel hub assembly.

• The vehicle speed detection magnetic encoder collects any metallic particle easily, because it is

magnetised. Make sure that the magnetic encoder should not collect any metallic particle. Check

that there is not any trouble prior to reassembling it.

• When the front wheel hub assembly is removed and installed, make sure that the vehicle speed

detection magnetic encoder does not contact with surrounding parts to avoid damage.

• When the front wheel speed sensor is removed and installed, make sure that its pole piece does

not contact with surrounding parts to avoid damage.

Post-installation Operation

• Check the dust cover for cracks or damage by pushing it

with your finger.

AC311040

N

7

4

1

9

13

80 ± 10 N·m

29 ± 4 N·m

108 ± 10 N·m

245 ± 29 N·m

80 ± 10 N·m

AC

12

14

11

8

100 ± 10 N·m

N

9.0 ± 2.0 N·m

10

3

2

6

5

89 ± 9 N·m

N

N

Removal

steps

<<A>> >>A<<

1. Drive shaft nut

>>A<<

2. Washer

3. Front wheel speed sensor

4. Brake

hose

bracket

5. Stabilizer link connection

<<B>>

6. Caliper assembly

<<C>>

7. Brake disc

8. Self-locking nut (lower arm ball joint

connection)

<<D>>

9. Self-locking nut (tie rod end

connection)

<<E>>

10. Drive shaft

11. Nut (hub and knuckle to strut

connection)

12. Knuckle

13. Front wheel hub assembly

14. Dust cover

Removal

steps

(Continued)