Mitsubishi L200. Manual - part 465

AC800980

AG

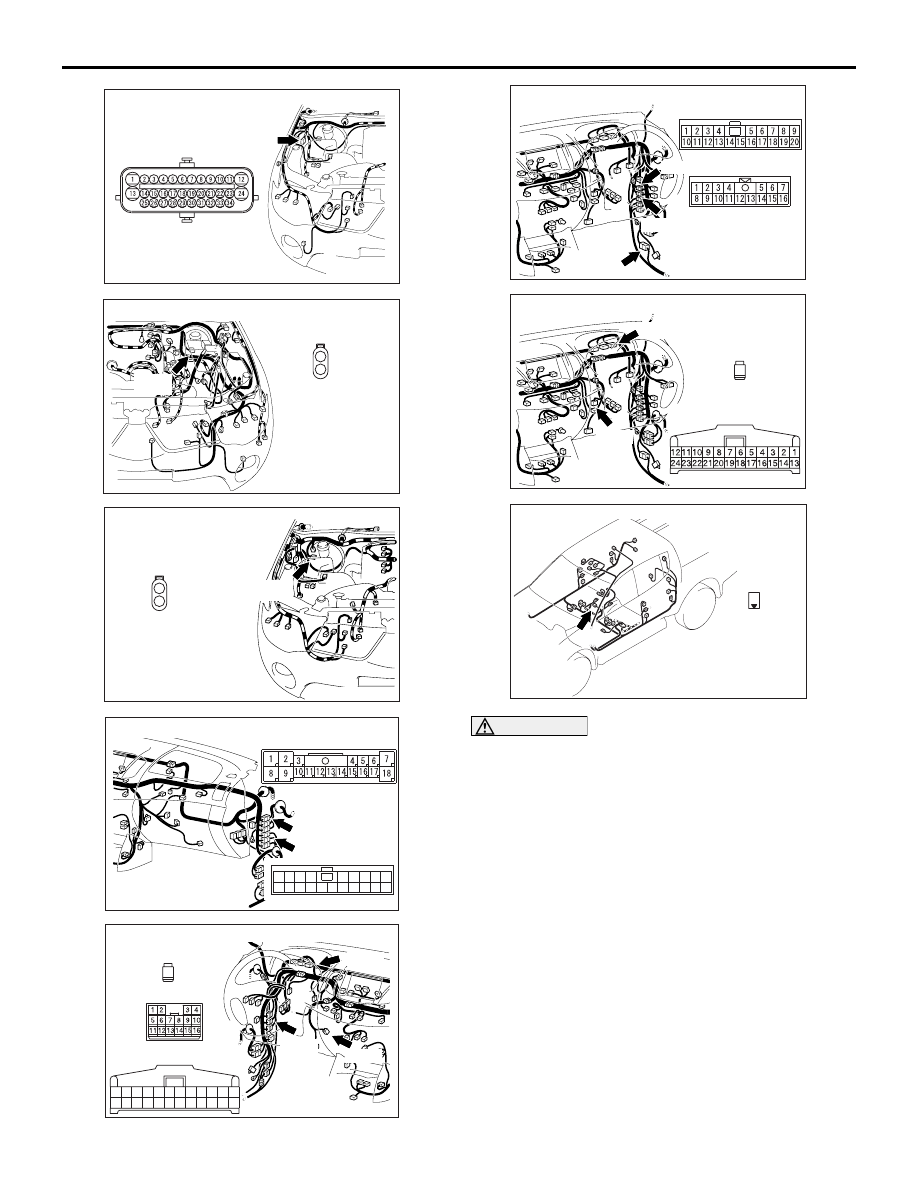

Connector: A-48

(B)

AC900745AB

Connector: A-102 <LHD>

(GR)

Harness connector

(harness side)

1

2

AC501971AS

Connector: A-102 <RHD>

Harness connector

(harness side)

1

2

(GR)

AC600688

Connector: C-13, C-59 <LHD>

BW

C-59

C-13

16

10

13

4

1112

1 2 3

15

14

5

20

18

17

19

7

6

8 9

C-59

C-13

AC600687CT

Connectors: C-47, C-54, C-113 <LHD>

C-54

C-54

C-47

C-113 Harness side

18

19

21

22

20

2423

11

12

10 9

7

8

6

1413

171615

3

4

5

1

2

C-113

1

C-47 Harness side

AC600623DI

Connector: C-13, C-14, C-59 <RHD>

C-13, C-59

C-14

C-59

C-14

C-13

AC600623DH

Connectors: C-47, C-113 <RHD>

Harness side

C-113

C-113

1

C-47 Harness side

C-47

AC509967AZ

Connector: D-19

Harness side

1

TROUBLESHOOTING

ACTIVE STABILITY & TRACTION CONTROL SYSTEM (ASTC)

35C-116

CAUTION

If there is any problem in the CAN bus lines, an

incorrect diagnosis code may be set. Diagnose

the CAN bus lines before the diagnosis codes

(Refer to GROUP 54C

− CAN Bus Diagnostics

Table .).

OPERATION

• ASTC-ECU send the illumination signal of Brake

warning lamp to the combination meter via the

CAN communication.

• ASTC-ECU operates the Brake warning lamp

and the Brake warning lamp for three seconds

after the ignition switch is turned "ON" position for

bulb check.

COMMENT

This may be caused by faults in the signal line, the

combination meter or the ASTC-ECU.

PROBABLE CAUSES

• Malfunction of the combination meter