Mitsubishi L200. Manual - part 383

AC500718

AB

MB990890

or

MB990891

Housing

tube

DIFFERENTIAL CARRIER AND FREE WHEELING CLUTCH <4WD>

FRONT AXLE

26-37

CAUTION

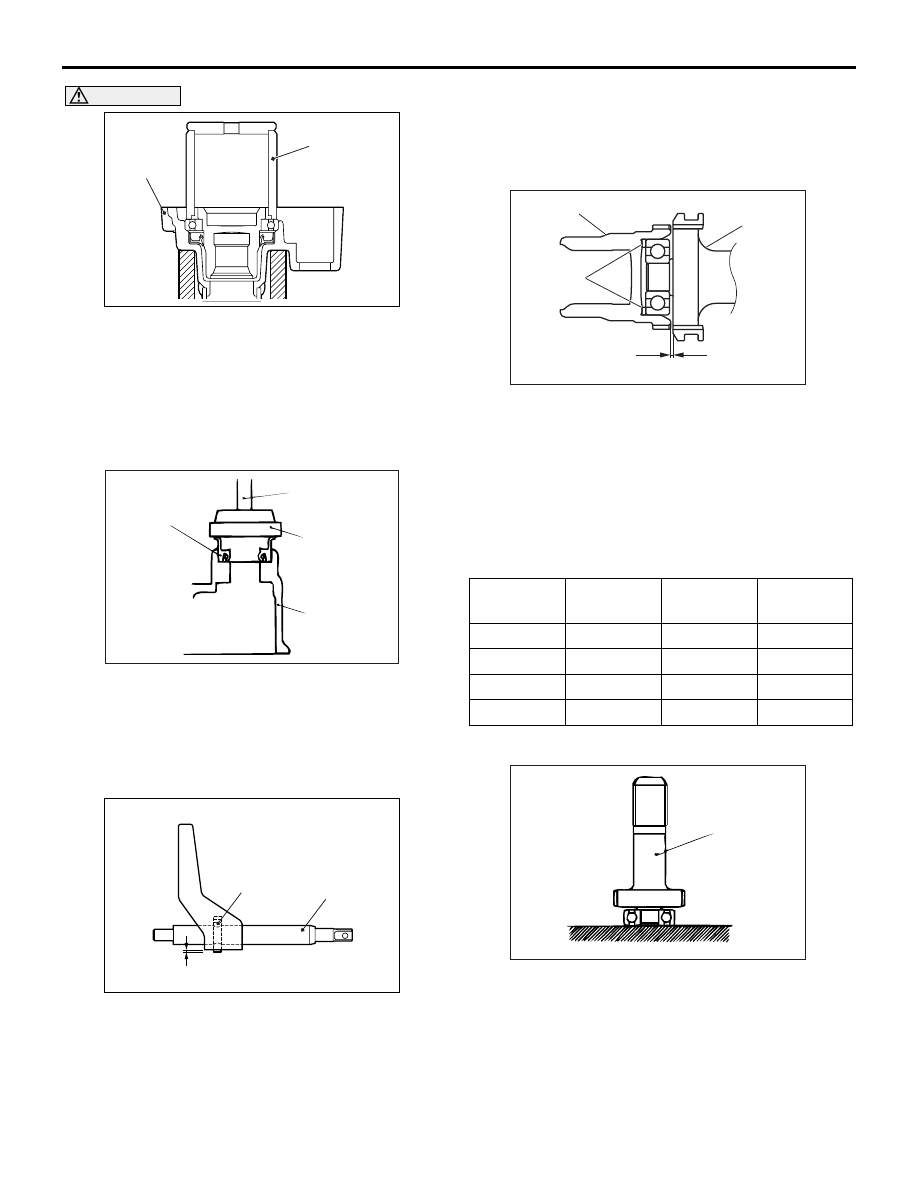

Place the special tool against the outer race of

the bearing.

2. Use special tool rear suspension housing base

(MB990890 or MB990891) to press-fit the bearing

to the side of the clutch housing.

>>C<<OIL SEAL INSTALLATION

ACX01029AC

Oil seal

MB990938

MB990926

Housing tube

Use the following special tools to press-fit the oil seal

to the clutch housing.

• Installer adapter (MB990926)

• Bar (MB990938)

>>D<< SPRING PIN INSTALLATION

AC500719

AB

Spring pin

Shift rod

0 – 1 mm

Tap the spring pin from the chamfered side of the

shaft rod until the projection length becomes the

length shown in the illustration.

>>E<< SPACER INSTALLATION

AC101906AB

Clutch gear

Main shaft

assembly

Spacer

A

1. Place the current spacer in the area shown in the

illustration to check that the dimensions shown in

the illustration are within the standard values.

Standard Value (A): 0.05

− 0.3 mm

2. If the dimensions are outside of the standard

values, select the correct spacer type to fit in the

standard values.

Spacer type

Part

Number

Thickness

mm

Part

Number

Thickness

mm

MR111526 1.1

MR111530 2.1

MR111527 1.35

MR111531 2.35

MR111528 1.6

MR111532 2.6

MR111529 1.85

MR111533 2.85

>>F<< BEARING/MAIN SHAFT INSTALLATION

ACX01031AB

Main shaft

Press-fit the bearing to the shoulder of the mainshaft.