Mitsubishi L200. Manual - part 301

ON-VEHICLE SERVICE

AUTOMATIC TRANSMISSION

23A-111

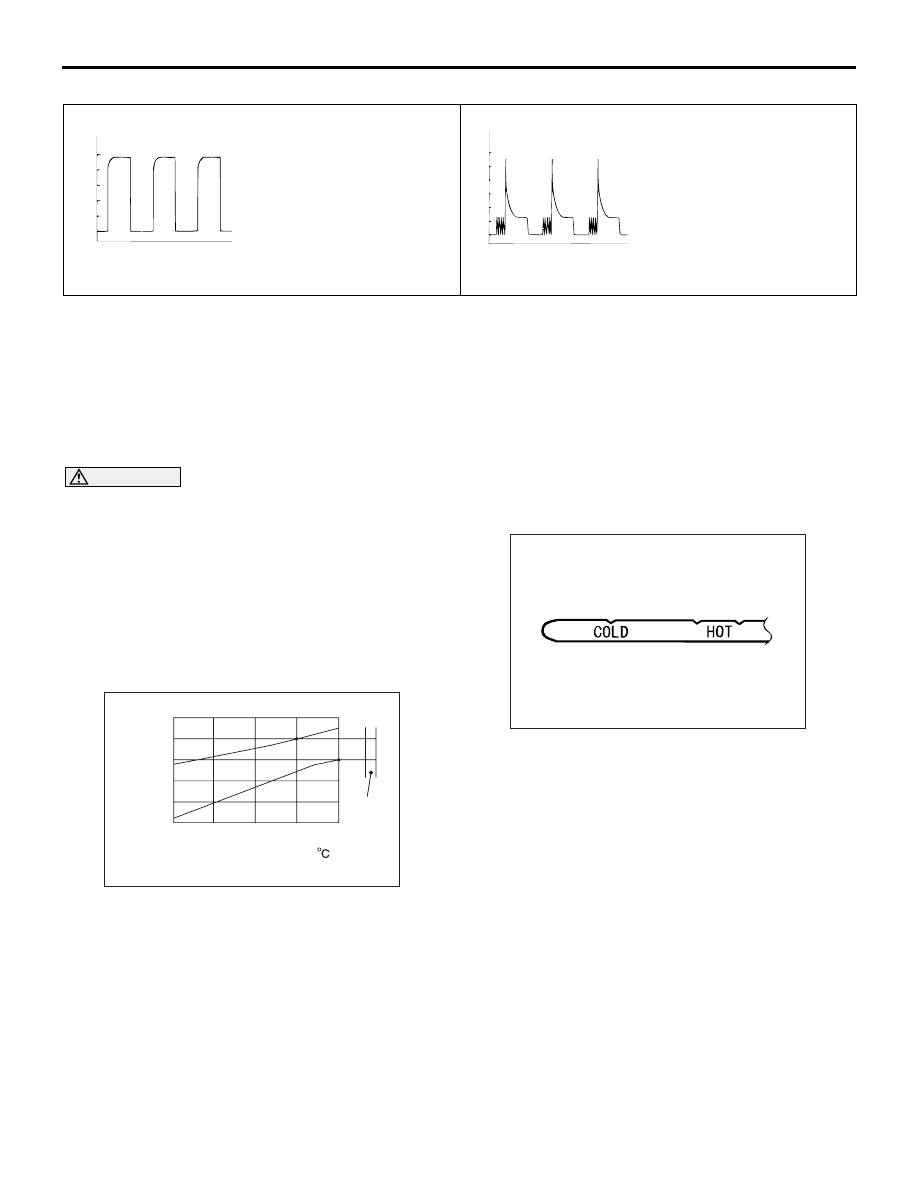

WAVEFORM SAMPLE

AC001874

(V)

Waveform A

0

5

AH

(ms)

AC001875

(V)

Waveform B

0

20

40

60

AJ

(ms)

ON-VEHICLE SERVICE

ESSENTIAL SERVICE

A/T FLUID CHECK

M1231103700212

CAUTION

When replacing the transmission with a new one,

overhauling the existing transmission, or driving

in a harsh condition, the A/T fluid cooler line

should always be flushed out and A/T fluid

should be replaced with a new one.

1. Drive the vehicle until the A/T fluid temperature

reaches the normal temperature (70

− 80°C)

NOTE: Measure A/T fluid temperature using

M.U.T.III.

NOTE:

AC503813

Fluid level

[mm]

A/T fluid temperature [ ]

10

0

-10

-20

-30

40

60

80

Gauge

AB

-40

HO

T

Check the fluid level referring to the characteris-

tics chart shown at left if it takes some time to

reach the normal operation temperature of A/T

fluid (70

−

80

°

C).

2. Park the vehicle on a level surface.

3. Move the selector lever to all positions to fully

charge the torque converter and the fluid lines

with A/T fluid, and then move the selector lever to

the P position.

4. After wiping away any dirt from around the oil

level gauge, pull out the oil level gauge and check

the level of A/T fluid.

NOTE: If the A/T fluid has a burnt smell, or if it has

become very contaminated or dirty, it means that

the A/T fluid has become contaminated by minute

particles form bushings (metal) or worn parts. In

such a case, the transmission needs to be over-

hauled and the A/T fluid cooler line needs to be

flushed out.

AC000846 AB

5. Check that the A/T fluid level is between the HOT

marks on the oil level gauge. If the A/T fluid level

is too low, add more A/T fluid until the level

reaches between the HOT marks.

Automatic transmission fluid: DIA QUEEN

ATF SP III

NOTE: If the A/T fluid level is too low, the oil pump

draws air into the system along with the A/T fluid,

and air bubbles will thus from in the fluid circuit.

This will cause a drop in fluid pressure and cause

the shift points to change and the clutches and

brakes to slip.

If the A/T fluid level is too high, the gear will churn

the A/T fluid and cause bubbles to develop, which

can then cause the same problems as when the

A/T fluid is too low.

In either case, the air bubbles can cause over-

heating and oxidation of the A/T fluid, and also