Mitsubishi L200. Manual - part 270

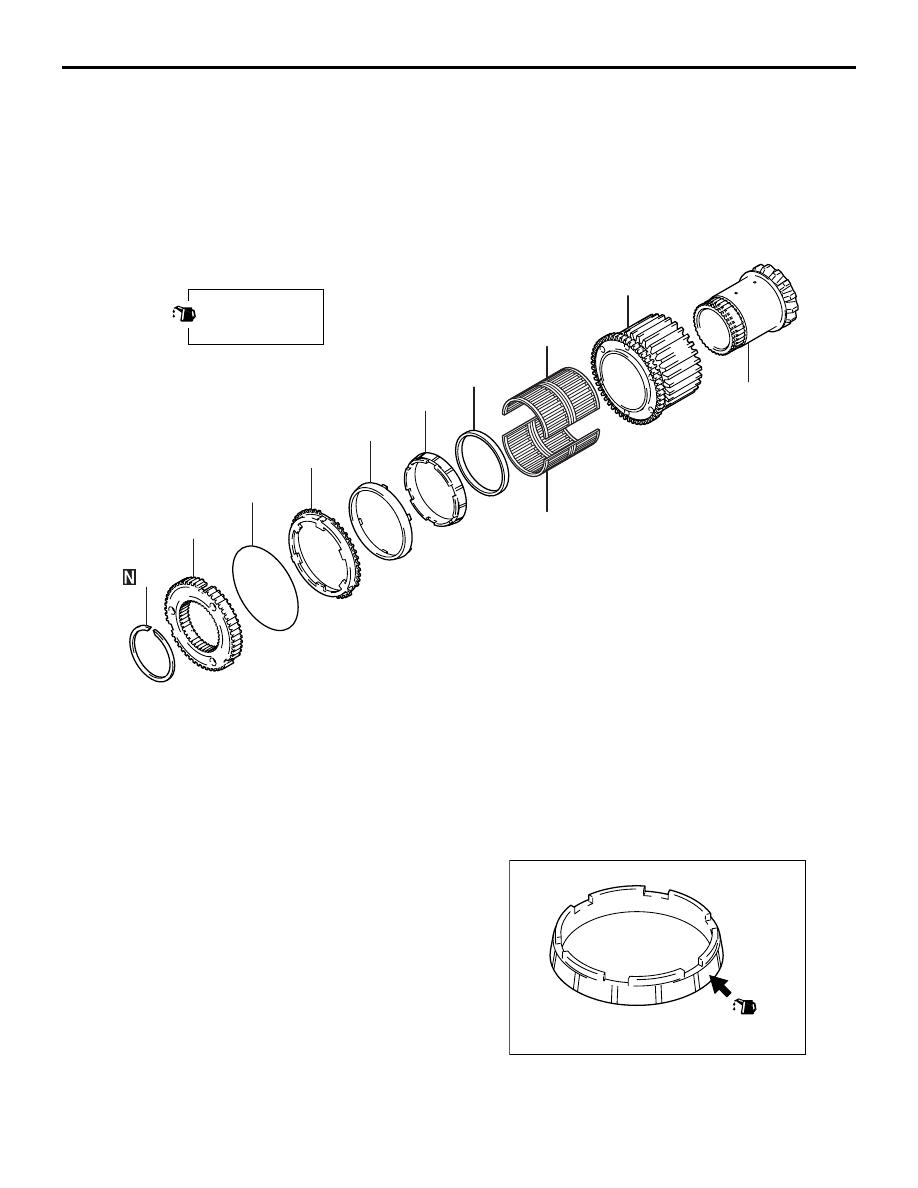

2-4WD SYNCHRONIZER <V5MB1-J-ND2, NEZ, PD2>

MANUAL TRANSMISSION OVERHAUL <V5MB1>

22C-65

2-4WD SYNCHRONIZER <V5MB1-J-ND2, NEZ, PD2>

DISASSEMBLY AND REASSEMBLY

M1222010900020

AK503423

4

5

6

1

2

3

7

9

9

8

10

AB

Apply gear oil to

all moving parts

before installation.

Disassembly steps

>>

C

<< 1.

Snap ring

2.

2-4WD Synchronizer hub

3.

2-4WD Synchronizer spring

>>

B

<< 4.

Outer synchronizer ring

5.

Synchronizer cone

>>

A

<< 6.

Inner synchronizer ring

7.

Drive sprocket

8.

Bearing spacer

9.

Needle bearing

10. Front side gear

REASSEMBLY SERVICE POINTS

>>A<< INNER SYNCHRONIZER RING INSTALLA-

TION

AK503426AB

Apply oil the synchronizer ring cone surface before

installation.