Mitsubishi L200. Manual - part 212

SPECIAL TOOLS

INTAKE AND EXHAUST

15-3

SPECIAL TOOLS

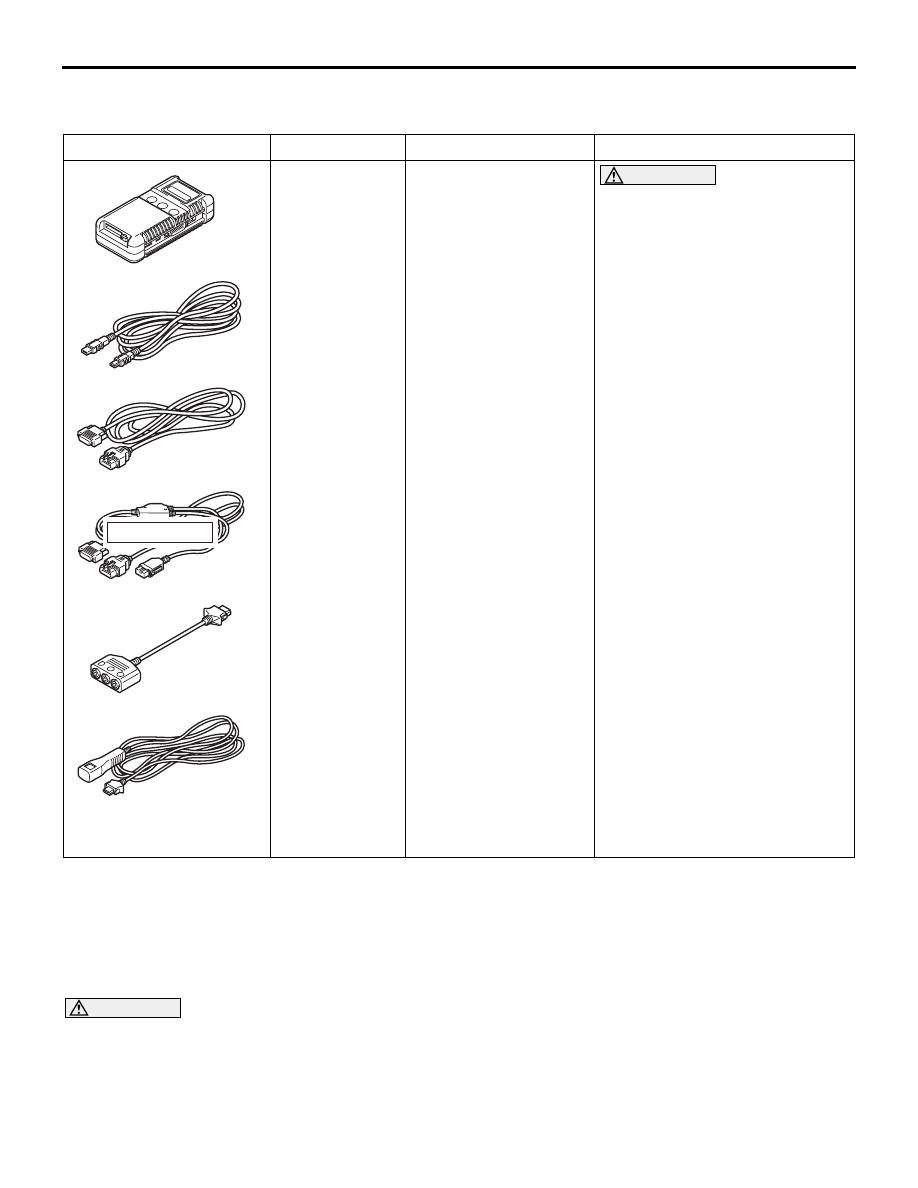

M1151000601842

Tool

Number

Name

Use

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USE

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826

M.U.T.-III sub assembly

A: Vehicle

communication

interface (V.C.I.)

B: M.U.T.-III USB cable

C: M.U.T.-III main

harness A (Vehicles

with CAN

communication

system)

D: M.U.T.-III main

harness B (Vehicles

without CAN

communication

system)

E: M.U.T.-III adapter

harness

F: M.U.T.-III trigger

harness

For vehicles with CAN

communication, use M.U.T.-III

main harness A to send

simulated vehicle speed. If you

connect M.U.T.-III main harness

B instead, the CAN

communication does not

function correctly.

Measurement of turbocharger

supercharging pressure

ON-VEHICLE SERVICE

TURBOCHARGER SUPERCHARGING

PRESSURE CHECK

M1151001001069

CAUTION

Conduct the driving test in a location where driv-

ing at full acceleration can be done with safety.

Two person should be in the vehicle when the

test is conducted; the person in the passenger

seat should read the indications shown by the

M.U.T.-III.

1. Set the vehicle to the pre-inspection condition.

CAUTION