Mitsubishi L200. Manual - part 198

ON-VEHICLE SERVICE

DIESEL FUEL

13A-588

ON-VEHICLE SERVICE

EVACUATION OF WATER FROM FUEL

FILTER

M1133001200406

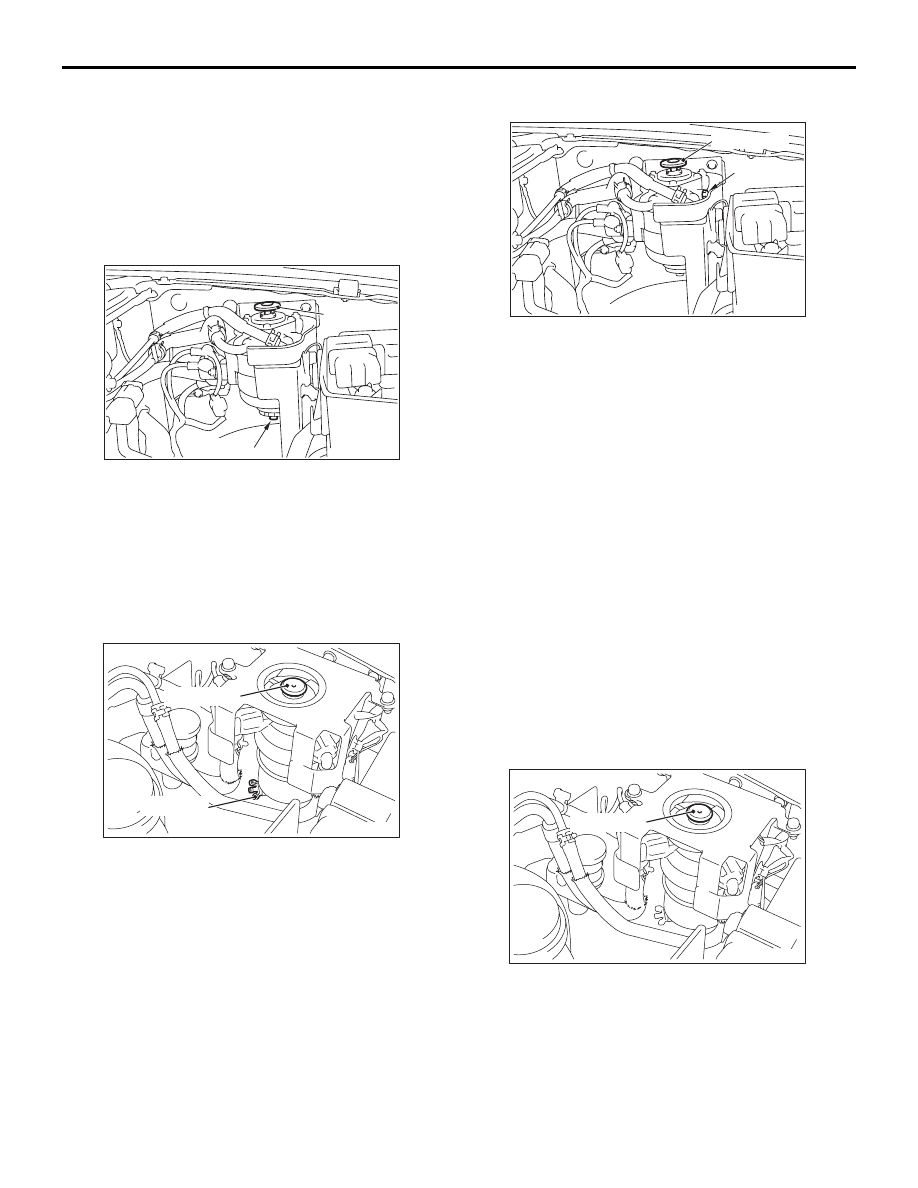

<Vehicles with steel fuel filter case>

Water is in the fuel filter when fuel filter indicator

lamp illuminates. Evacuate water by the following

procedures.

1. Loosen the drain plug.

2. After water is evacuated by using an hand pump,

tighten the drain plug.

<Vehicles with plastic fuel filter case>

Water is in the fuel filter when fuel filter indicator

lamp illuminates. Evacuate water by the following

procedures.

1. Loosen the drain plug.

2. After water is evacuated by using an hand pump,

tighten the drain plug.

EVACUATION OF AIR FROM FUEL LINE

M1133001300362

<Vehicles with steel fuel filter case>

When the following service work(s) is done, refill the

fuel tank and then evacuate air from the fuel line.

• Fuel hose or pipe is removed

• Fuel filter is replaced

• Fuel injector is removed

• If necessary for access, fuel is drained from the

fuel tank.

1. Remove the fuel filter air plug and O-ring

<Vehicles with air plug>.

2. Cover the circumference of the air plug hole with

cloth and use a hand pump repeatedly until no

bubbles come out of the air plug hole <Vehicles

with air plug>.

3. Replace the air plug and O-ring with a new one.

Tighten the air plug to the specified torque

<Vehicles with air plug>.

Tightening torque: 5.0

± 1.0 N⋅m

4. Repeat until the hand pump operation becomes

stiff.

<Vehicles with plastic fuel filter case>

When the following service work(s) is done, refill the

fuel tank and then evacuate air from the fuel line.

• Fuel hose or pipe is removed

• Fuel filter is replaced

• Fuel injector is removed

• If necessary for access, fuel is drained from the

fuel tank.

1. Repeat until the hand pump operation becomes

stiff.

FUEL FILTER REPLACEMENT

M1133010800387

<Vehicles with steel fuel filter case>

Refer to GROUP 13B

− Fuel Filter .

AC506328AB

Hand pump

Drain plug

ACB01923AB

Hand pump

Drain plug

AC503662AB

Hand pump

Air plug

ACB01924AB

Hand pump