Mitsubishi L200. Manual - part 124

TROUBLESHOOTING

DIESEL FUEL

13A-292

OPERATION

• The electrical current source is supplied from the

engine control relay (terminal No. 3) to the glow

control unit (terminal No. 6). Also, it is supplied

from the glow control unit (terminal No.7) to the

body earth.

• The request signal of operating the glow plug is

input into the glow control unit (terminal No. 1)

from the engine-ECU (terminal No.120).

• The voltage for the glow plug is applied from the

battery to the glow control unit (terminal No. 10).

• The voltage is applied from the glow control unit

(terminal No.1, 2, 3 and 4) to each glow plug.

• The diagnosis signal is output from the glow con-

trol unit (terminal No. 9) to the engine-ECU (ter-

minal No. 126).

FUNCTION

• The voltage applied to the glow control unit (ter-

minal No.10) from the battery is applied to each

glow plug in the duty ratio according to the signal

from the engine ECU.

TROUBLE JUDGMENT

Check Conditions

• While the engine is running

• The electrical continuity duty to the glow plug is

17

− 83 %.

Judgment Criterion

• The diagnosis signal is not received from the

glow control unit for more than 5 seconds.

PROBABLE CAUSES

• Failed glow control unit

• Open/short circuit or harness damage in glow

control unit power supply/earth circuit or loose

connector contact.

• Loose connector contact; open/short circuit or

harness damage of communication wire between

glow control unit and engine-ECU.

• Failed engine-ECU

DIAGNOSTIC PROCEDURE

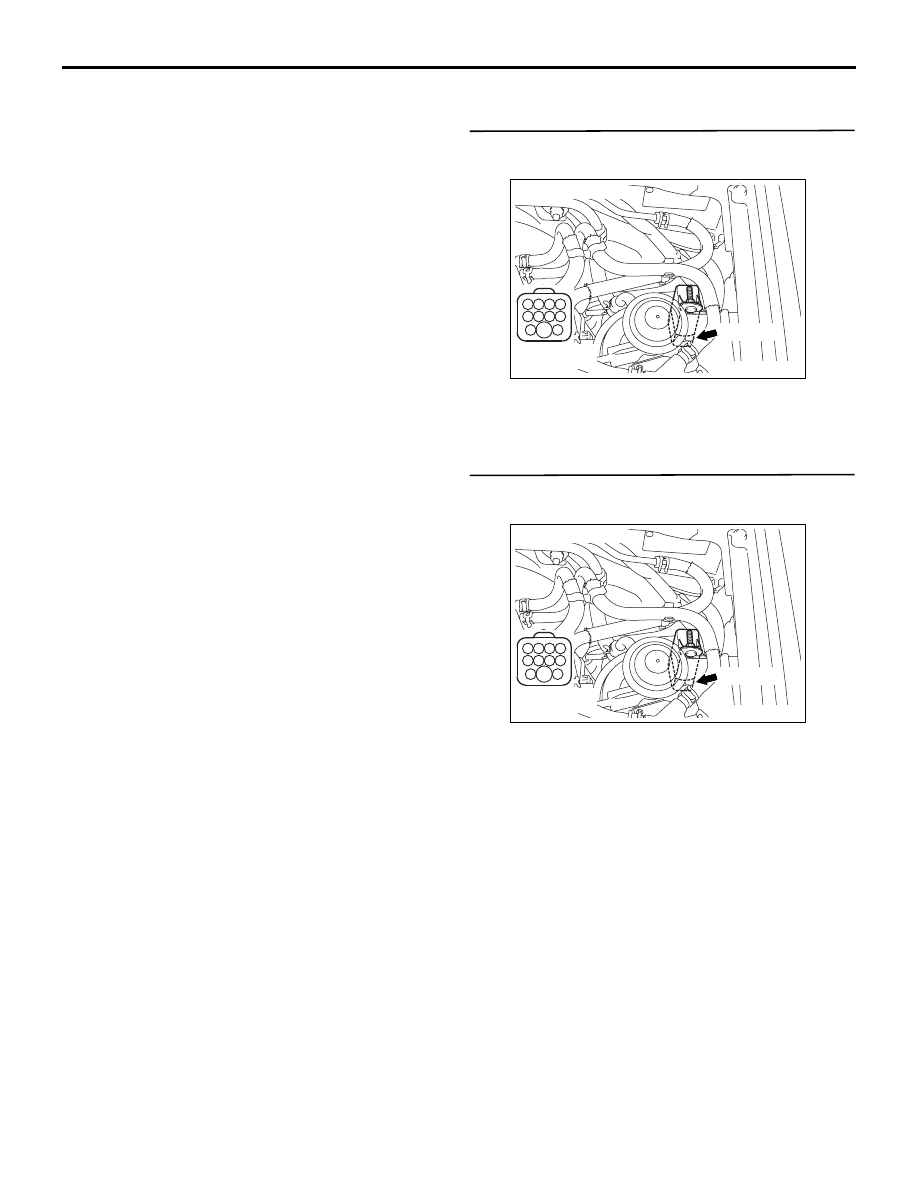

STEP 1. Connector check: A-151 glow control

unit connector

Q: Is the check result normal?

YES :

Go to Step 2 .

NO :

Repair or replace the connector.

STEP 2. Perform voltage measurement at A-151

glow control unit connector.

• Disconnect connector, and measure at harness

side.

• Ignition switch: ON

• Voltage between terminal No. 6 and earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 4 .

NO :

Go to Step 3 .

AKB00264

4 3 2 1

8 7 6 5

11 10 9

AB

A-151 (B)

Harness side

connector

Connector: A-151

AKB00264

4 3 2 1

8 7 6 5

11 10 9

AB

A-151 (B)

Harness side

connector

Connector: A-151