Mitsubishi L200. Manual - part 10

PRECAUTIONS BEFORE SERVICE

GENERAL

00-36

NOTE:

.

•

*

1

: Vehicles with rear step bumper assembly.

PRECAUTIONS BEFORE SERVICE

SERVICING COMMON RAIL ENGINE

M1001016400154

DANGER

•

The working near to a naked flame or

sparks must be avoided.

•

Attention during engine running:

a.

Do not work on the high pressure fuel

circuit.

b.

Always remain out of the way of possi-

ble fuel jet that may result in serious

injuries.

c.

Do not place your hand near the high

pressure fuel circuit.

•

Attention before service:

a.

After turning the ignition switch to the

"LOCK" (OFF) position, wait for 30 sec-

onds before starting any repair

work.This period of time is required so

that the high pressure fuel circuit pres-

sure can get back to the atmospheric

pressure.

b.

After turning the ignition switch to the

"LOCK" (OFF) position, wait 10 min-

utes before disconnecting the fuel

return pipe from diesel injectors.

VEHICLES WITH SEMI AUTOMATIC AIR

CONDITIONER STARTING

M1001011300077

CAUTION

Never start the engine with the refrigerant system

empty as it will damage the A/C compressor.

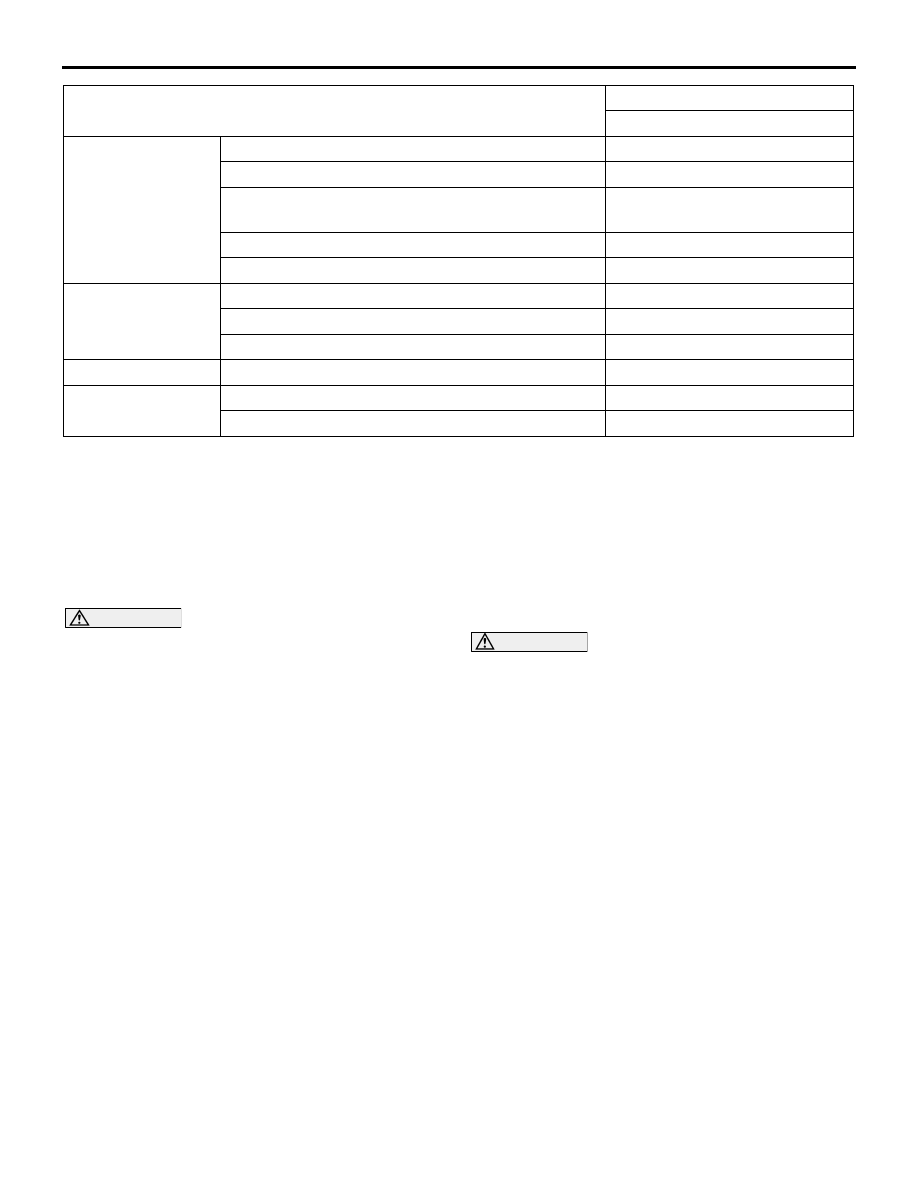

Engine

Model code

4D56

Total displacement mL

2,477

Type

DOHC diesel

Intercooled, Turbocharger

Max. output kW/rpm (EEC net)

94/4,000

Max. torque N

⋅m/rpm (EEC net)

240/1,500

− 3,500

Transmission

Model code

R5MB1

Type

5M/T

Drive system

Rear wheel drive 2WD

Fuel system

Fuel supply system

Electrical fuel injection

Turning radius m

Body

6.1

Wheel

5.7

Item

KA4T

NENMZ6BA