Mitsubishi L200. Manual - part 2

HOW TO USE THIS MANUAL

GENERAL

00-4

EXPLANATION OF MANUAL CONTENTS

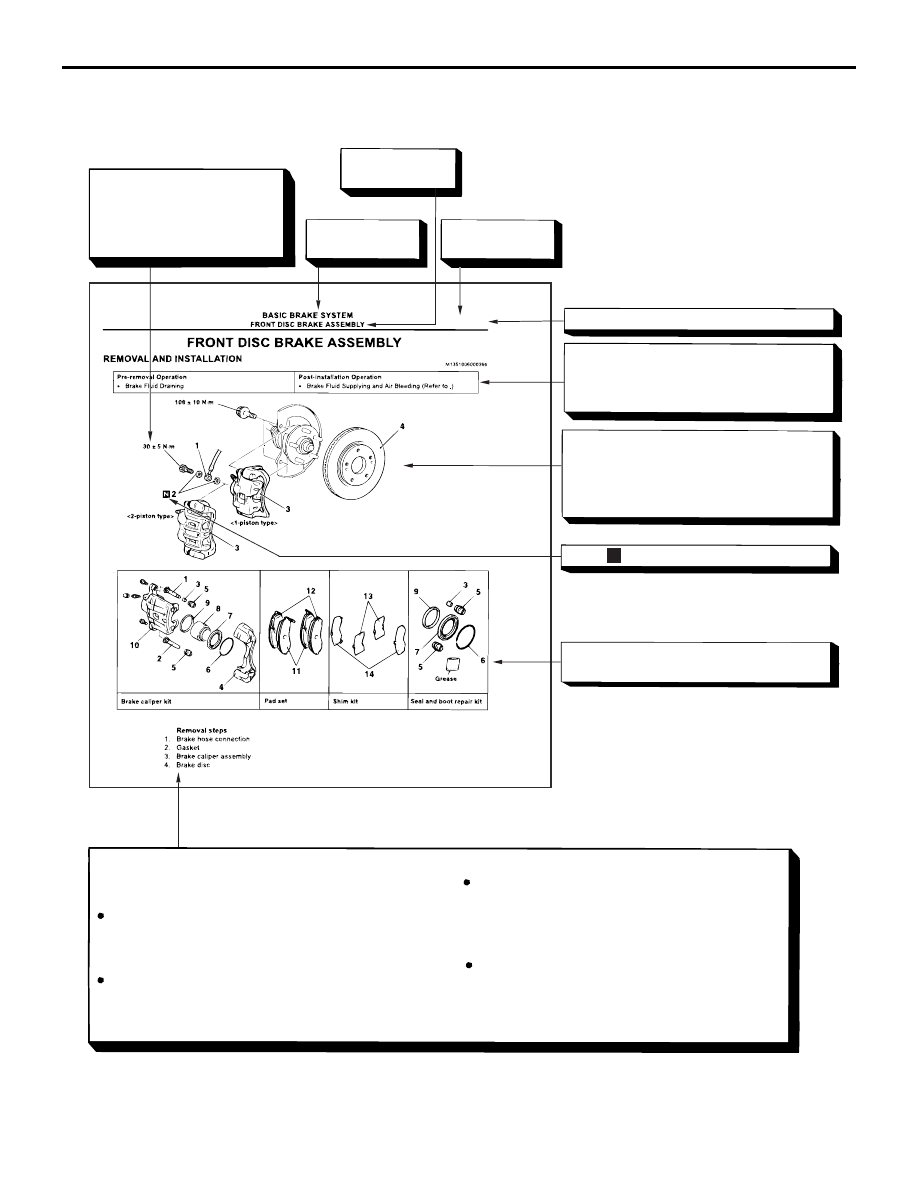

AC311238

N

Denotes tightening torque.

For bolts and nuts which do

not have a tightening torque

listed, refer to the "Standard

Parts tightening-torque Table"

Indicates the

group title.

Indicates the

section title.

Indicates the

group number.

Indicates the page number.

Indicates procedures to be performed be-

fore the work in that section is started, and

procedures to be performed after the work

in that section is finished.

Component diagram

A diagram of the component parts is pro-

vided near the front of each section in order

to give the reader a better understanding of

the installed condition of component parts.

Mark denotes nonreusable part.

Repair kit or parts sets are shown.

(Only very frequently used parts are shown.)

Removal steps :

The part designation number corresponds to

the number in the illustration to indicate remov-

al steps.

Disassembly steps :

The part designation number corresponds to

the number in the illustration to indicate disas-

sembly steps.

Installation steps :

Specified in case installation is impossible in

reverse order of removal steps. Omitted if

installation is possible in reverse order of re-

moval steps.

Reassembly steps :

Specified in case installation is impossible in

reverse order of removal steps. Omitted if

reassembly is possible in reverse order of dis-

assembly steps.

Maintenance and servicing procedures

The numbers provided within the diagram indicate the

sequence for maintenance and servicing procedures.

AE

>>A<<

>>B<<

35A-19