Mazda Training manual - part 237

3 – SHORT BLOCK

33

Piston Engine Fundamentals

TC010-05-01S

5. The gap between the main bearings and the main journals is called

_____________________ .

6. The _____________________ half of the crankshaft main bearing has oil holes and fits

into the ___________________ .

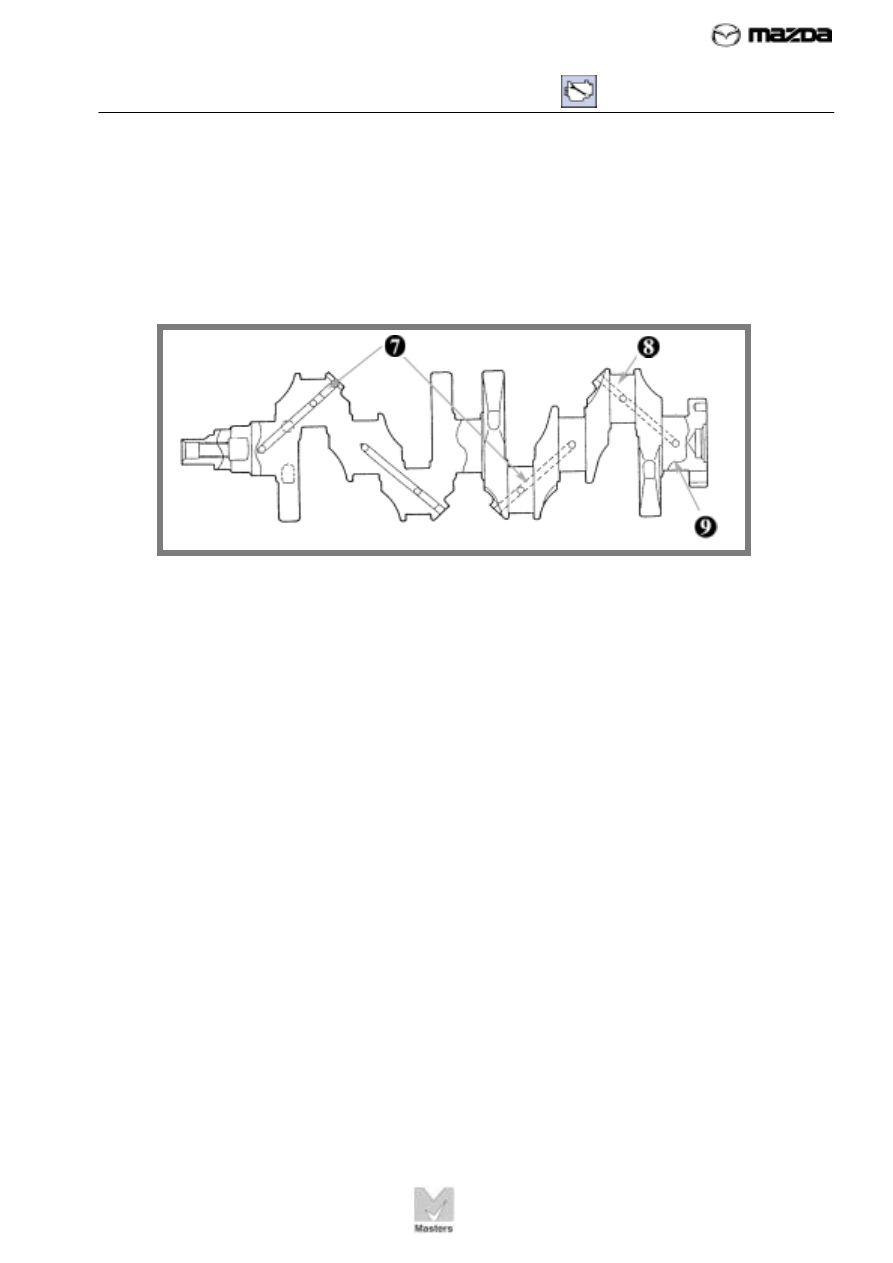

Match the numbered items on the crankshaft drawing to the definitions below.

7. _______

A.

main journal

8. _______

B.

oil passages

9. _______

C.

crankpin

10. Which of these symptoms would you expect to find in an engine that has worn main

bearings? More than one answer may be correct.

A. low oil pressure

B. leaking gasoline

C. hard starting

D. low rattle noise from engine