Mazda Training manual - part 16

Powertrain Engines

•

Due to the large bathub shaped combustion chambers the rotary engine is equipped with

two spark plugs per rotor housing, improving combustion efficiency and exhaust

emissions

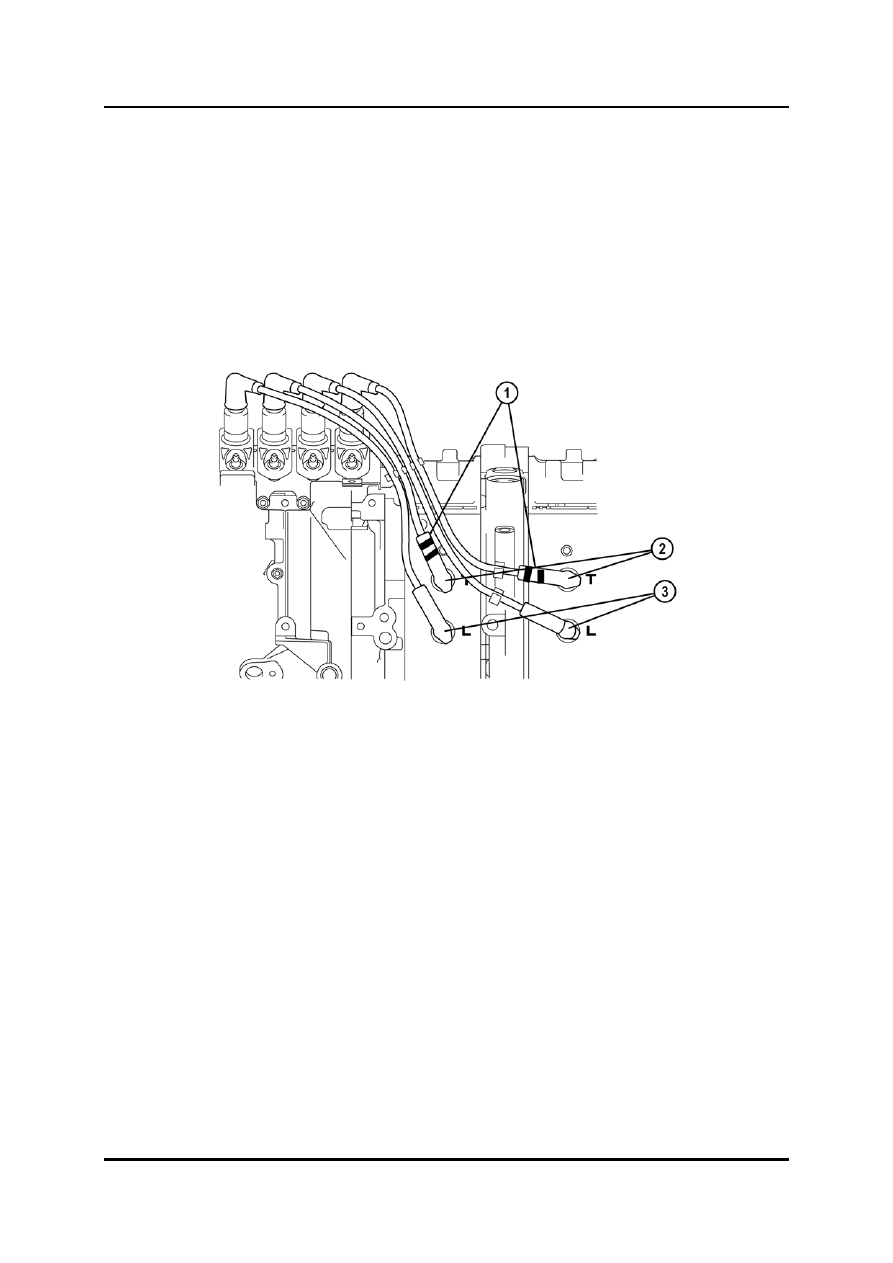

NOTE: Two different spark plugs (leading and trailing) with different lengths are mounted in

each rotor housing. If a wrong spark plug is used the engine may be damaged (e.g. a

spark plug which is too long may contact the rotor).

•

The high tension leads for the trailing spark plugs are marked with blue and green tape

to prevent incorrect installation.

L1001.4_01137

1

Blue and green tape

3

Leading spark plugs

2

Trailing spark plugs

Curriculum Training

01-51