Mazda Engine SKYACTIV-G 2.5. Manual - part 3

GENERAL INFORMATION

00-00–6

ABBREVIATIONS

id000000010100

End Of Sie

GAIHAN: -

FUNDAMENTAL PROCEDURES

id000000750100

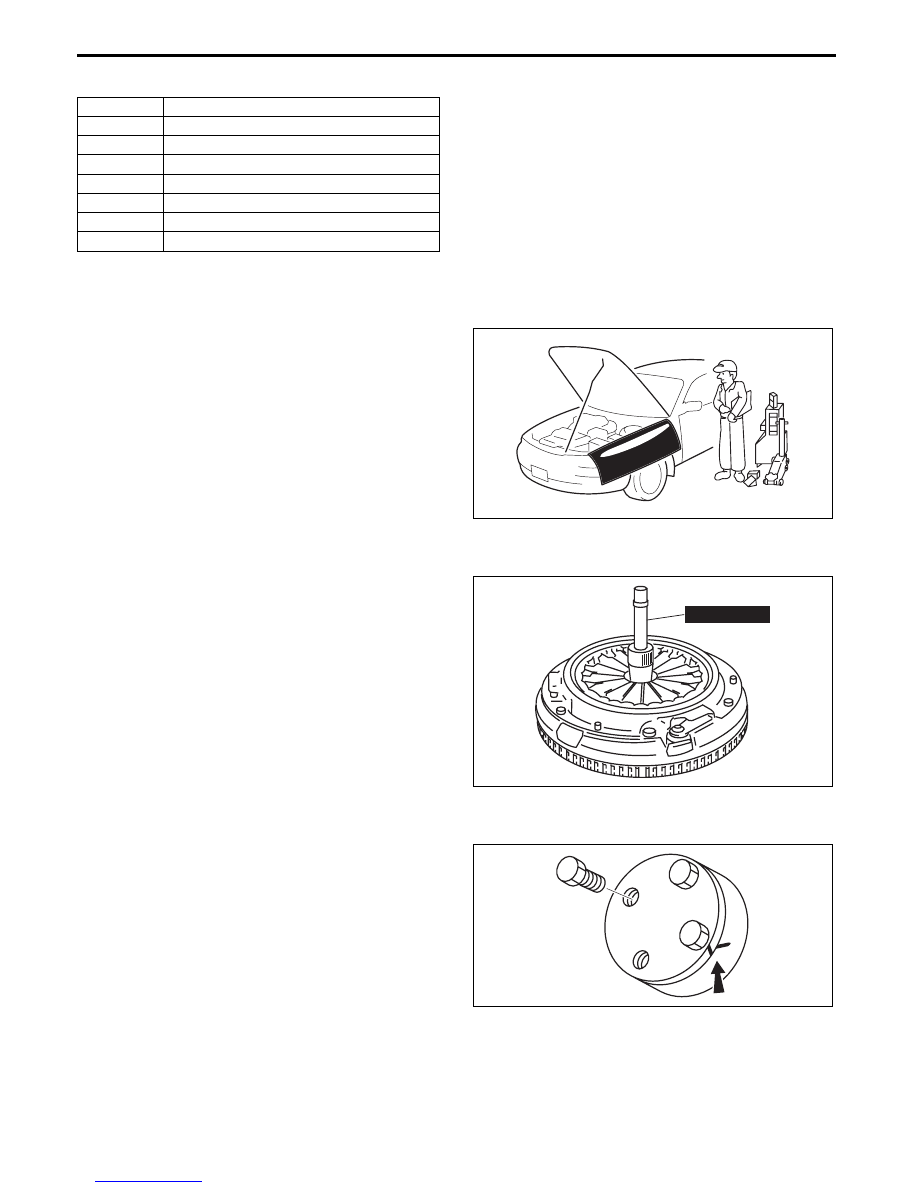

Preparation of Tools and Measuring Equipment

• Be sure that all necessary tools and measuring

equipment are available before starting any work.

Special Service Tools

• Use special service tools or equivalent when they

are required.

Disassembly

• If the disassembly procedure is complex,

requiring many parts to be disassembled, all parts

should be marked in a place that will not affect

their performance or external appearance and

identified so that reassembly can be performed

easily and efficiently.

ATX

Automatic Transaxle

EX

Exhaust

HLA

Hydraulic Lash Adjuster

IN

Intake

MTX

Manual Transaxle

OCV

Oil Control Valve

TDC

Top Dead Center

SST

Special Service Tool

bpe2ue00000110

49 SE01 310

bpe2ue00000111

bpe2ue00000112