Mazda CX 7. Manual - part 380

GLASS/WINDOWS/MIRRORS

09-12–7

09-12

10. Remove the rear power window regulator through

the speaker installation hole.

11. Install in the reverse order of removal.

Caution

• Make sure the cable does not unspool

from the drum housing when installing.

End Of Sie

WM: WINDOW MOTOR

POWER WINDOW MOTOR REMOVAL/INSTALLATION

id091200803700

1. Fully lower the rear door glass.

2. Disconnect the negative battery cable.

3. Remove the following parts:

Front door

• Inner garnish (See.09-17-20 INNER GARNISH REMOVAL/INSTALLATION)

• Front door trim (See.09-17-20 FRONT DOOR TRIM REMOVAL/INSTALLATION)

Rear door

• Sail garnish (See.09-17-12 SAIL GARNISH REMOVAL/INSTALLATION)

• Rear door trim (See.09-17-23 REAR DOOR TRIM REMOVAL/INSTALLATION)

4. Remove the bolts.

5. Remove the power window motor from the power

window regulator.

6. Disconnect the power window motor connector.

7. Install in the reverse order of removal.

Note

• When installing the power window motor to

the power window regulator drum, the drum

housing tabs may detach from the door

module. If this happens, insert a hand

through the speaker installation hole to

engage the drum housing tabs, and install

the power window motor to the drum while

supporting the drum housing.

End Of Sie

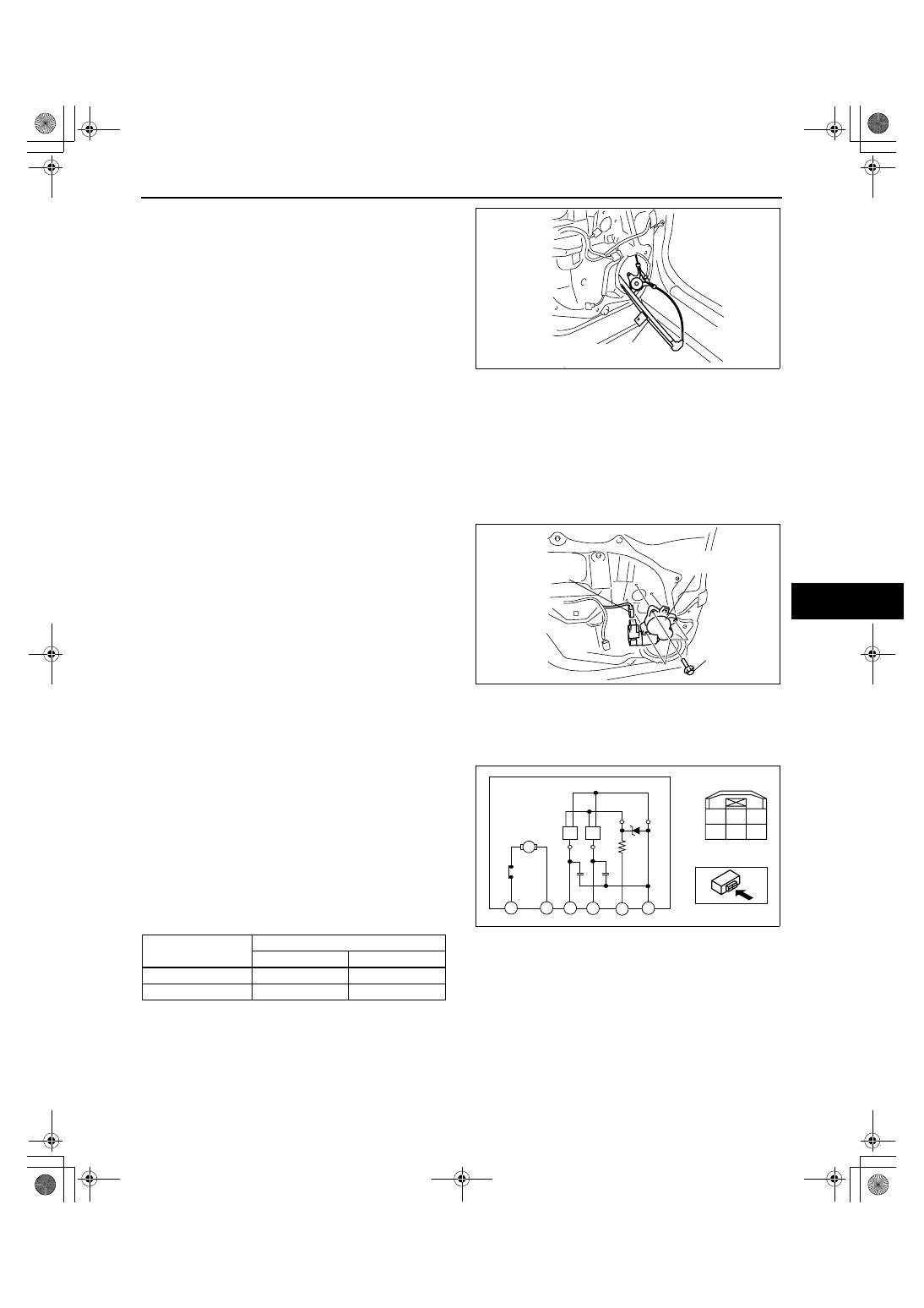

POWER WINDOW MOTOR INSPECTION

id091200800800

Front Side

1. Apply battery positive voltage and connect the

ground to power window motor terminals E and F,

and then inspect the power window motor

operation.

• If the power window motor does not operate

as indicated in the table, replace it.

Caution

• If the power window motor temperature is

high, the motor may not rotate due to the

motor internal bimetal function. Leave it

untouched for about 3 min to cool it

down, then reinspect.

2. Connect the battery positive voltage to power window motor terminal D and connect terminal C to ground.

3. Operate the power window motor and measure the voltage at terminals A and B.

• If there is any malfunction, replace the power window motor.

Voltage

• Pulse: max. 12 V/min. 0 V

REAR POWER WINDOW

REGULATOR

acxuuw00001471

POWER WINDOW

MOTOR

POWER WINDOW

MOTOR CONNECTOR

6.2—8.2 N·m

{64—83 kgf·cm,

55—72 in·lbf}

BOLT

acxuuw00001506

Operation

Terminal

F

E

Open

B+

Ground

Close

Ground

B+

F

A

C

E

B

D

F

M

E

B

A

D

C

acxuuw00001507