Mazda CX 7. Manual - part 293

BASIC SYSTEM

07-11–17

07-11

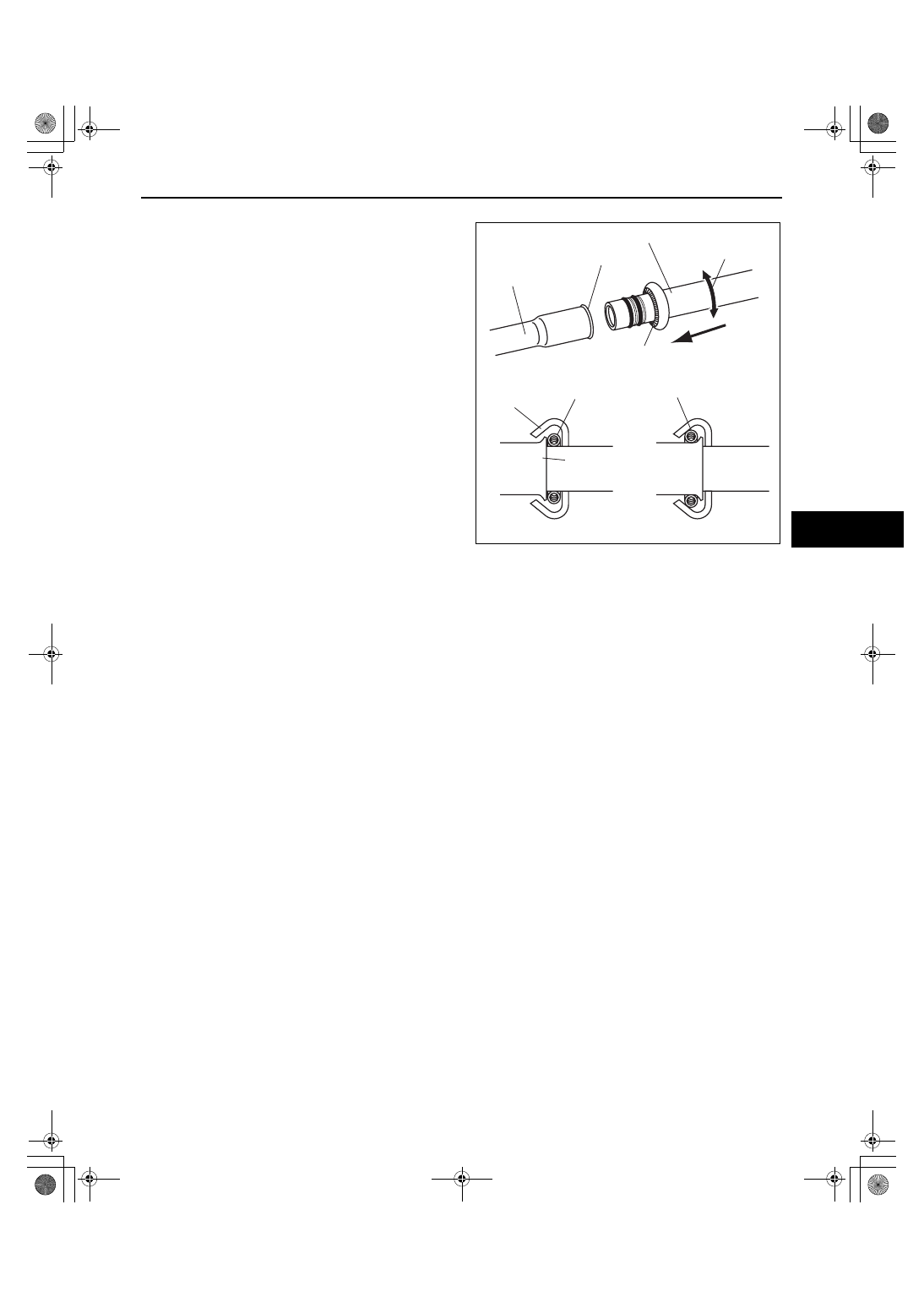

Spring-lock coupling type

1. Connect the male pipe or hose by pushing it while

slightly twisting it onto female pipe until the garter

spring at the male pipe or hose is over the flared

end of female pipe.

Note

• When the male pipe or hose is replaced, the

indicator ring comes out after connecting to

indicate that it is locked.

End Of Sie

WM: CONDENSER

CONDENSER REMOVAL/INSTALLATION

id071100801200

1. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system. (See 07-10-6 REFRIGERANT RECOVERY.) (See 07-10-2

REFRIGERANT CHARGING.)

3. Remove the air cleaner. (See 01-13-5 INTAKE AIR SYSTEM REMOVAL/INSTALLATION[L3 WITH TC].)

4. Remove the splash shield.

5. Drain the engine coolant. (See 01-12-5 ENGINE COOLANT REPLACEMENT[L3 WITH TC].)

6. Remove the following parts:

(1) Charge air cooler duct, air cleaner and fresh air duct component (See 01-13-5 INTAKE AIR SYSTEM

REMOVAL/INSTALLATION[L3 WITH TC].)

(2) Coolant reserve tank (See 01-12-7 COOLANT RESERVE TANK REMOVAL/INSTALLATION[L3 WITH TC].)

(3) Dipstick pipe (See 01-11-6 OIL PAN REMOVAL/INSTALLATION[L3 WITH TC].)

(4) Cooling fan component (See 01-12-12 FAN MOTOR REMOVAL/INSTALLATION[L3 WITH TC].)

7. Remove the radiator. (See 01-12-8 RADIATOR REMOVAL/INSTALLATION[L3 WITH TC].)

Caution

• If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug all open fittings after removing any

refrigeration cycle parts to keep moisture or foreign material out of the cycle.

8. Remove in the order indicated in the table. Do not allow compressor oil to spill.

FLARED END

FEMALE PIPE

MALE PIPE OR HOSE

GARTER SPRING

CAGE

SECTION

GARTER SPRING

SPRING IS OVER

THE FLARED END

FLARED

END

WRONG

RIGHT

SLIGHTLY TWISTING

PUSHING

acxuuw00000787

1871-1U-06B(07-11).fm 17 ページ 2006年3月15日 水曜日 午前11時30分