Mazda CX 7. Manual - part 285

SYMPTOM TROUBLESHOOTING

07-03–13

07-03

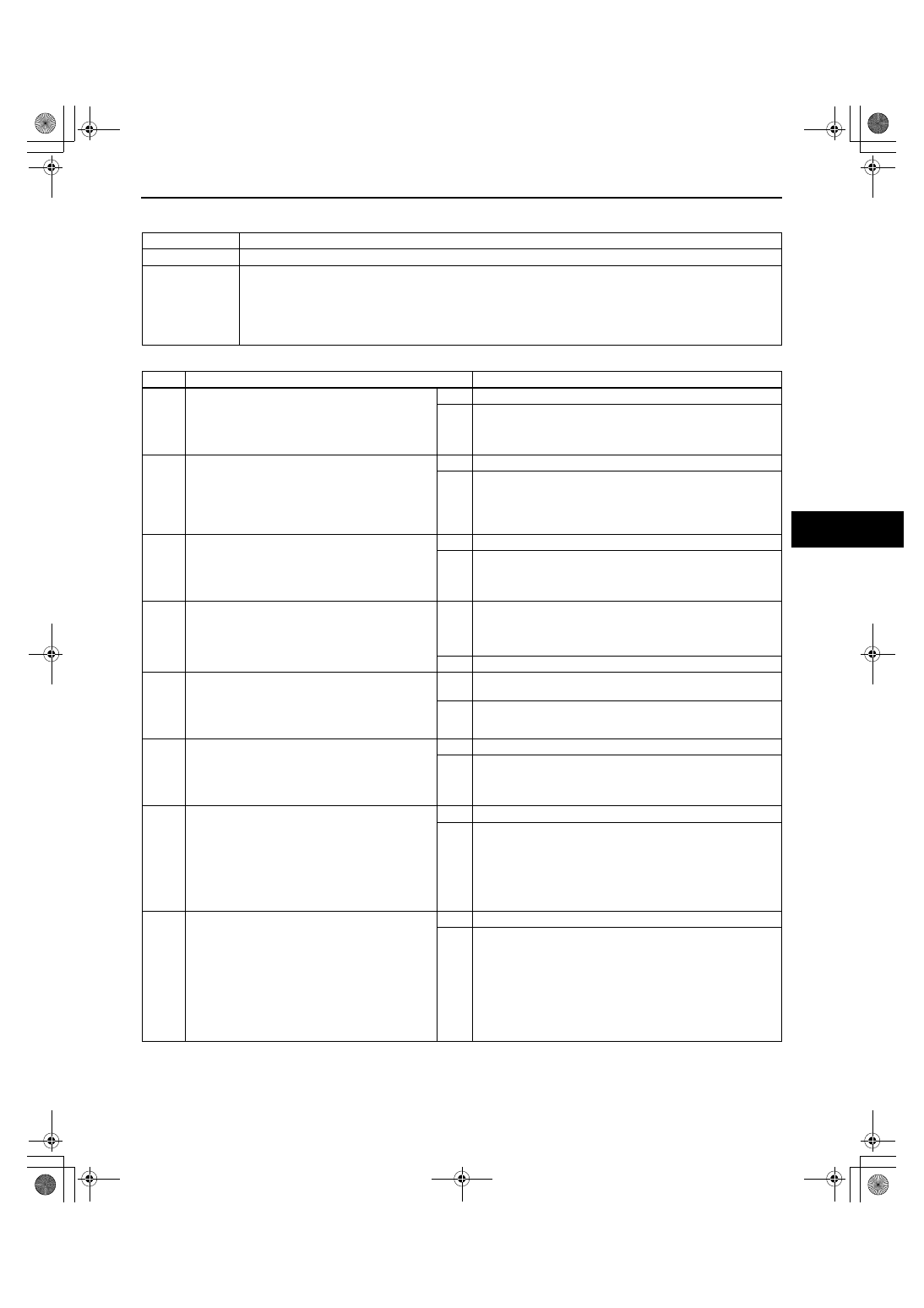

NO.7 AIR FROM VENTS NOT COLD ENOUGH

id070300801000

Diagnostic procedure

7

Air from vents not cold enough.

DESCRIPTION

• Magnetic clutch operates but A/C system malfunctions.

POSSIBLE

CAUSE

• Drive belt malfunction

• A/C unit or condenser malfunction

• Receiver/drier or expansion valve malfunction (valve closes too much)

• Malfunction in refrigerant lines

• A/C compressor system malfunction, insufficient compressor oil

• Over filling of compressor oil, malfunction in expansion valve or A/C unit air mix link system

STEP

INSPECTION

ACTION

1

INSPECT DRIVE BELT

• Inspect the drive belt.

(See 01-10-3 DRIVE BELT INSPECTION[L3

WITH TC].)

• Is it normal?

Yes

Go to the next step.

No

Adjust or replace the drive belt, then go to Step 20.

(See 01-10-3 DRIVE BELT REMOVAL/INSTALLATION[L3

WITH TC].)

2

INSPECT REFRIGERANT SYSTEM

PERFORMANCE

• Perform refrigerant system performance test.

(See 07-10-6 REFRIGERANT SYSTEM

PERFORMANCE TEST.)

• Is the operation normal?

Yes

Operation is normal. (Recheck malfunction symptoms.)

No

Go to the next step.

3

INSPECT TO SEE WHETHER MALFUNCTION

IS IN A/C UNIT INTAKE AND CONDENSER

OR ELSEWHERE

• Are the refrigerant high-pressure and low-

pressure values both high?

Yes

Go to the next step.

No

Go to Step 6.

4

INSPECT A/C UNIT INTAKE

• Is the A/C unit intake clogged?

Yes

Remove obstruction, then go to Step 20. (If air does not

reach the evaporator in the A/C unit, heat exchange does

not occur and refrigerant pressure becomes high.

Therefore, removal of obstruction is necessary.)

No

Go to the next step.

5

INSPECT CONDENSER

• Inspect the condenser.

(See 07-11-18 CONDENSER

INSPECTION.)

• Is it normal?

Yes

Adjust refrigerant to the specified amount, then go to Step

20. (Excessive amount of refrigerant.)

No

Replace the condenser, or repair and clean the condenser

fins, then go to Step 20.

6

INSPECT TO SEE WHETHER MALFUNCTION

IS IN EXPANSION VALVE, RECEIVER/DRIER

AND REFRIGERANT LINES OR ELSEWHERE

• Are the refrigerant high-pressure and low-

pressure values low?

Yes

Go to the next step.

No

Go to Step 14.

7

INSPECT TO SEE WHETHER MALFUNCTION

IS IN EXPANSION VALVE AND RECEIVER/

DRIER OR ELSEWHERE

• Immediately after the A/C compressor

operates, does the refrigerant high-pressure

value momentarily rise to correct value, then

fall and stay below it? (Is there negative

pressure on low-pressure side?)

Yes

Go to the next step.

No

Go to Step 10.

8

INSPECT TO SEE WHETHER MALFUNCTION

IS IN EXPANSION VALVE OR RECEIVER/

DRIER

• Turn the A/C switch off and let the air

conditioner stop for 10 min.

• Start the engine.

• Turn the both A/C switch and airflow volume

control dial on.

• Does the malfunction occur after the A/C

compressor turns on?

Yes

Go to the next step.

No

Replace the condenser and vacuum the refrigerant line

more than 30 min by the vacuum pump, add refrigerant to

the specified level, then go to Step 20. (Since water has

intermixed in the receiver/drier and it is saturated,

replacement is necessary.)

1871-1U-06B(07-03).fm 13 ページ 2006年3月15日 水曜日 午前11時28分