Mazda CX 7. Manual - part 212

CONVENTIONAL BRAKE SYSTEM

04-11–19

04-11

Piston Disassembly Note

Warning

• When compressed air is blown into the caliper body, injury to a finger or other part from pinching

could result from the piston springing up. When blowing in compressed air, do not place your

fingers between the piston and caliper body when performing the work.

Caution

• The piston could be damaged if blown out with great force. Blow the compressed air slowly to

prevent the piston from suddenly popping out.

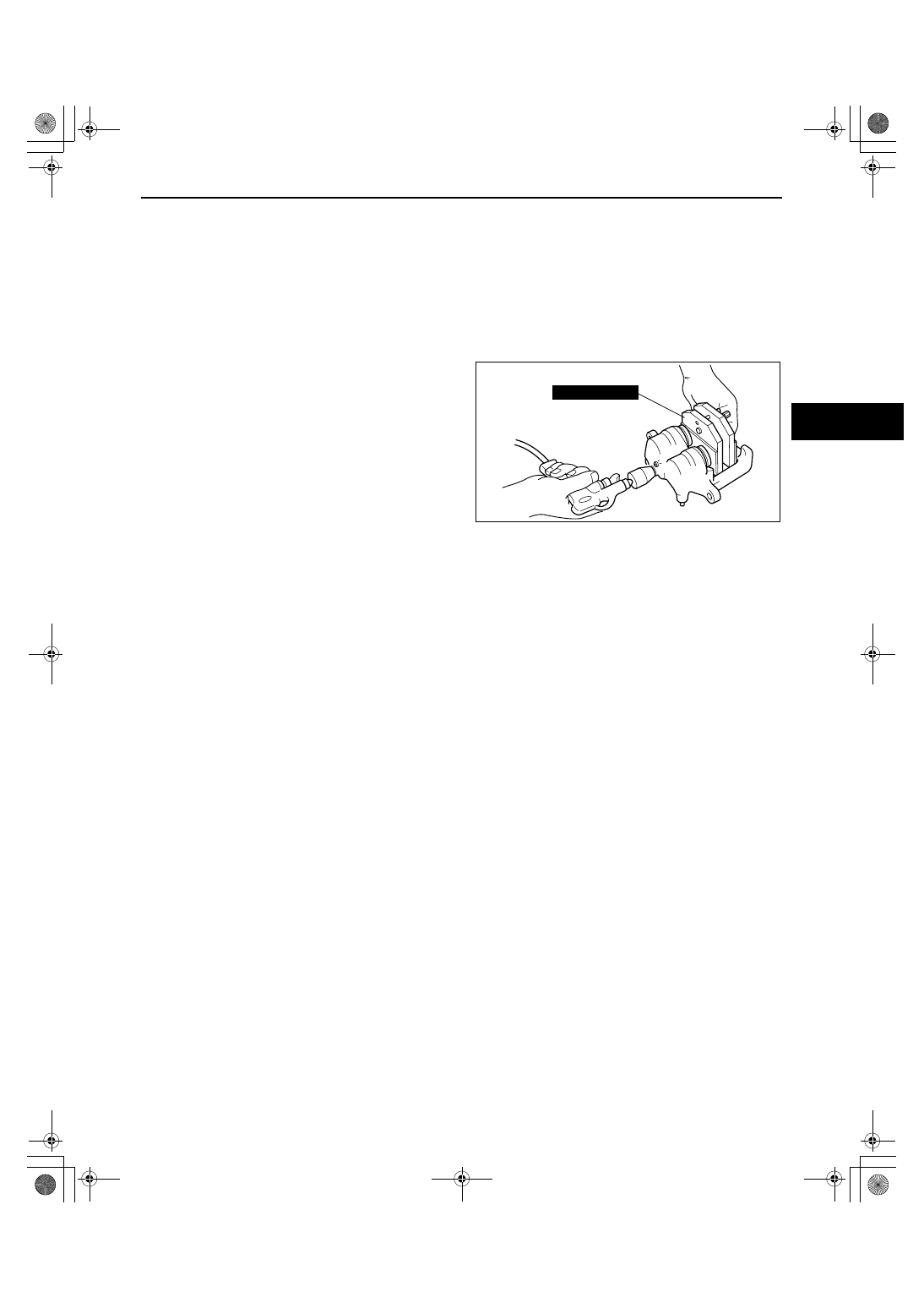

1. Place the SST in the caliper, then blow

compressed air through the hole to force the

piston out of the caliper.

End Of Sie

WM: REAR BRAKE (DISC)

REAR BRAKE (DISC) INSPECTION

id041100800400

Brake Judder Repair Hint

Description

Brake judder concern has the following three characteristics:

Steering wheel vibration

Steering wheel vibrates in the direction of its rotation. This characteristic is most noticeable when applying brakes

at a vehicle speed of 100— 140 km/h {62— 87 mph}.

Floor vibration

When applying brakes, the vehicle body shakes back and forth. The seriousness of shake is not influenced by

vehicle speed.

Brake pedal vibration

When applying brakes, a pulsating force tries to push the brake pad back. The pulsation is transmitted to the brake

pedal.

The following are the main possible causes of brake judder:

Due to an excessive runout (side-to-side wobble) of disc plate, the thickness of disc plate is uneven.

If the runout is more than 0.05 mm {0.002 in} at the position 10 mm {0.39 in} from the disc plate edge, uneven

wear occurs on the disc plate because of uneven pad/plate contact.

If the runout is less than 0.05 mm {0.002 in}, uneven wear does not occur.

The disc plate is deformed by heat.

Repeated panic braking may raise the temperature in some portions of disc plate by approx. 1,000

°C {1,832 °F}.

This results in deformed disc plate.

Due to corrosion, the thickness and friction coefficient of disc plate change.

If a vehicle is parked under damp conditions for a long time, corrosion occurs on the friction surface of disc plate.

The thickness of corrosion is uneven and sometimes appears like a wave pattern, which changes the friction

coefficient and causes a reaction force.

49 T033 001A

acxuuw00001887

1871-1U-06B(04-11).fm 19 ページ 2006年3月15日 水曜日 午前11時13分