Mazda CX 7. Manual - part 119

INTAKE-AIR SYSTEM [L3 WITH TC]

01-13–15

01-13

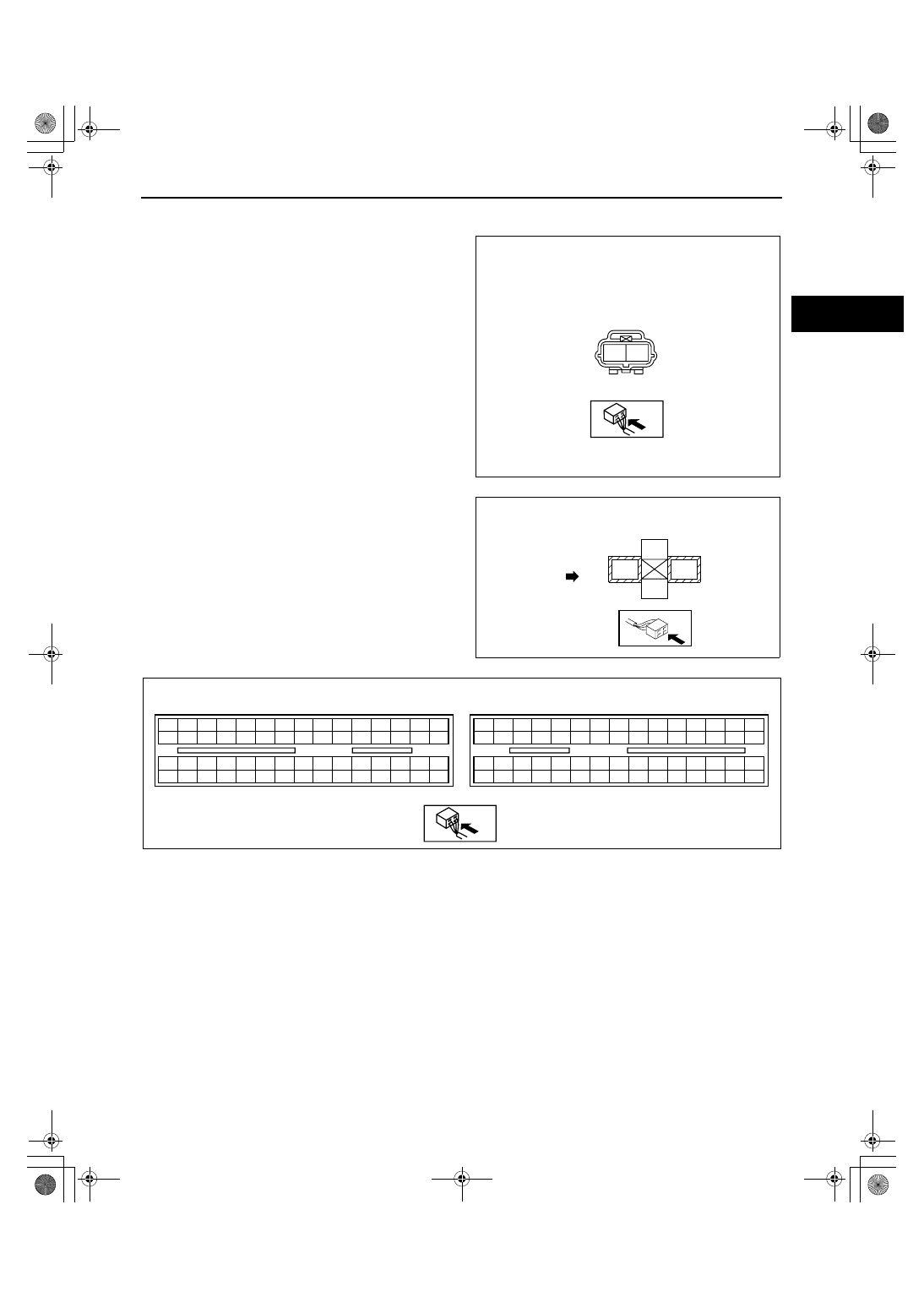

Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See01-40-6 PCM REMOVAL/INSTALLATION[L3 WITH TC].)

2. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

• If there is no continuity, there is an open circuit. Repair or replace the wiring harness.

— Wastegate control solenoid valve terminal B and PCM terminal 2AA

— Wastegate control solenoid valve terminal A and main relay terminal E

Short circuit

• If there is continuity, there is a short circuit. Repair or replace the wiring harness.

— Wastegate control solenoid valve terminal A and body ground

— Wastegate control solenoid valve terminal B and power supply

— Wastegate control solenoid valve terminal B and body ground

End Of Sie

WASTEGATE CONTROL

SOLENOID VALVE

WIRING HARNESS SIDE CONNECTOR

A

B

acxuuw00000032

FUSE BOX

(MAIN RELAY)

A

E

B

D

FRONT

acxuuw00002335

2BE 2BA 2AW 2AS 2AO 2AK 2AG 2AC 2Y 2U 2Q 2M

2E

2A

2I

2BH 2BD 2AZ 2AV 2AR 2AN 2AJ 2AF 2AB 2X 2T 2P

2H

2D

2L

2BG 2BC 2AY 2AU 2AQ 2AM 2AI 2AE 2AA 2W 2S 2O

2G

2C

2K

2BF 2BB 2AX 2AT 2AP 2AL 2AH 2AD 2Z

2V 2R 2N

2F

2B

2J

1BE 1BA 1AW 1AS 1AO 1AK 1AG 1AC 1Y 1U 1Q 1M

1E

1A

1I

1BH 1BD 1AZ 1AV 1AR 1AN 1AJ 1AF 1AB 1X

1T

1P

1H

1D

1L

1BG 1BC 1AY 1AU 1AQ 1AM 1AI 1AE 1AA 1W 1S 1O

1G

1C

1K

1BF 1BB 1AX 1AT 1AP 1AL 1AH 1AD 1Z

1V

1R 1N

1F

1B

1J

PCM

WIRING HARNESS-SIDE CONNECTOR

acxuuw00000033

1871-1U-06B(01-13).fm 15 ページ 2006年3月15日 水曜日 午前10時44分