Mazda CX 7. Manual - part 81

SYMPTOM TROUBLESHOOTING [L3 WITH TC]

01-03–21

01-03

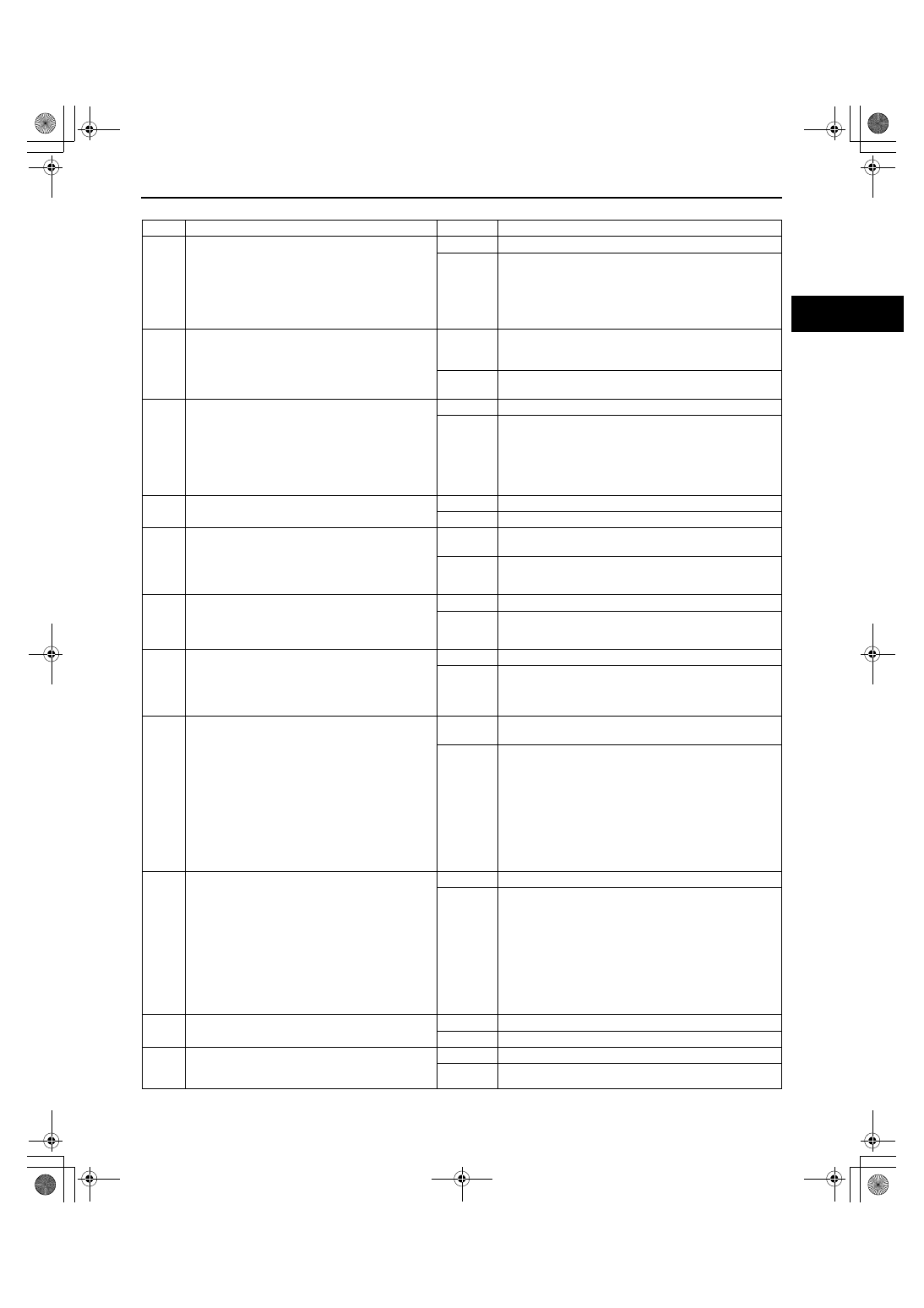

Diagnostic procedure

STEP

INSPECTION

RESULTS

ACTION

1

Inspect for the following:

• Fuel quality (proper octane, contamination,

winter/summer blend)

• Fuel leakage

• Intake-air system leakage or restriction

• Vacuum leakage

Are all items normal?

Yes

Go to the next step.

No

Service if necessary.

Repeat Step 1.

2

Perform the self-test function using the M-MDS.

Turn the ignition switch to the ON position.

Retrieve any DTCs.

Is a DTC displayed?

Yes

DTC is displayed:

Go to the appropriate DTC test.

(See01-02-13 DTC TABLE[L3 WITH TC].)

No

No DTC is displayed:

Go to the next step.

3

Access the ECT PID using the M-MDS.

Verify that the ECT PID isless than 116

°C

{241

°F} during driving.

Is the ECT PID less than specified?

Yes

Go to the next step.

No

The cause of this concern could be from the cooling

system overheating.

Perform the symptom troubleshooting “NO.17

COOLING SYSTEM CONCERNS - OVERHEATING.”

(See01-03-60 NO.17 COOLING SYSTEM

CONCERNS-OVERHEATING[L3 WITH TC].)

4

Will the engine run smoothly at part throttle?

Yes

Go to the next step.

No

Go to Step 6.

5

Perform the TP sweep inspection.

(See01-03-78 ENGINE CONTROL SYSTEM

OPERATION INSPECTION[L3 WITH TC].)

Does the electronic throttle control system work

properly?

Yes

Visually inspect the throttle body (damage/scratching.)

If normal, go to the next step.

No

Inspect or replace the malfunctioning parts, according

to the inspection results.

6

Perform the EGR system operation inspection.

(See01-03-78 ENGINE CONTROL SYSTEM

OPERATION INSPECTION[L3 WITH TC].)

Does the EGR system operate properly?

Yes

Go to the next step.

No

Inspect or replace the malfunctioning parts, according

to the inspection results.

7

Perform the Purge Control System Operation

inspection.

(See01-03-78 ENGINE CONTROL SYSTEM

OPERATION INSPECTION[L3 WITH TC].)

Does the purge solenoid valve work properly?

Yes

Go to the next step.

No

Inspect or replace the malfunctioning parts, according

to the inspection results.

8

Inspect the CMP and CKP sensor for the

following;

• Installation condition

(See01-40-45 CAMSHAFT POSITION

(CMP) SENSOR REMOVAL/

INSTALLATION[L3 WITH TC].)

(See01-40-42 CRANKSHAFT POSITION

(CKP) SENSOR REMOVAL/

INSTALLATION[L3 WITH TC].)

• Damaged trigger wheel and camshaft

• Open or short circuit in the wiring harnesses.

Is there any malfunction detected?

Yes

Repair or replace the malfunctioning part according to

the inspection results.

No

Go to the next step.

9

Access and monitor following the PIDs using the

data monitor function.

• ECT

• MAF

• O2S11

• O2S12

• LONGFT1

• SHTFT1

Do the PIDs indicate the correct values under

trouble condition?

(See01-40-6 PCM INSPECTION[L3 WITH TC].)

Yes

Go to the next step.

No

Inspect and repair or replace suspected parts and the

related harnesses.

If the malfunction remains, perform the intermittent

concern troubleshooting.

(See01-03-76 INTERMITTENT CONCERN

TROUBLESHOOTING[L3 WITH TC].)

10

Remove and shake the PCV valve.

Does the PCV valve rattle?

Yes

Go to the next step.

No

Replace the PCV valve.

11

Inspect for restriction in the exhaust system and

the three-way catalytic converter (TWC).

Is there any restriction?

Yes

Replace the malfunctioning part.

No

Go to the next step.

1871-1U-06B(01-03).fm 21 ページ 2006年3月15日 水曜日 午前10時36分