Mazda CX 7. Manual - part 28

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–67

01-02

Diagnostic procedure

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA AND

DIAGNOSTIC MONITORING TEST RESULTS

HAVE BEEN RECORDED

• Have the FREEZE FRAME DATA and

DIAGNOSTIC MONITORING TEST RESULTS

(Engine cooling system related) been

recorded?

Yes

Go to the next step.

No

Record the FREEZE FRAME DATA and DIAGNOSTIC

MONITORING TEST RESULTS on the repair order, then

go to the next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

• Verify related Service Bulletins and/or on-line

repair information availability.

• Is any related repair information available?

Yes

Perform the repair or diagnosis according to the available

repair information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

INSPECT POOR CONNECTION OF ECT

SENSOR CONNECTOR FOR POOR

CONNECTION

• Turn the ignition switch off.

• Disconnect ECT sensor connector.

• Inspect for poor connection (such as damaged/

pulled-out pins, corrosion.)

• Is there any malfunction?

Yes

Repair or replace the terminal, then go to Step 9.

No

Go to the next step.

4

CLASSIFY ECT SENSOR MALFUNCTION OR

WIRING HARNESS MALFUNCTION

• Connect the M-MDS to the DLC-2.

• Access the ECT PID.

• Connect a jumper wire between ECT sensor

terminals A and B.

• Verify the ECT value.

• Is the voltage 4.6 V or below?

Yes

Replace the ECT sensor, then go to Step 9.

No

Go to the next step.

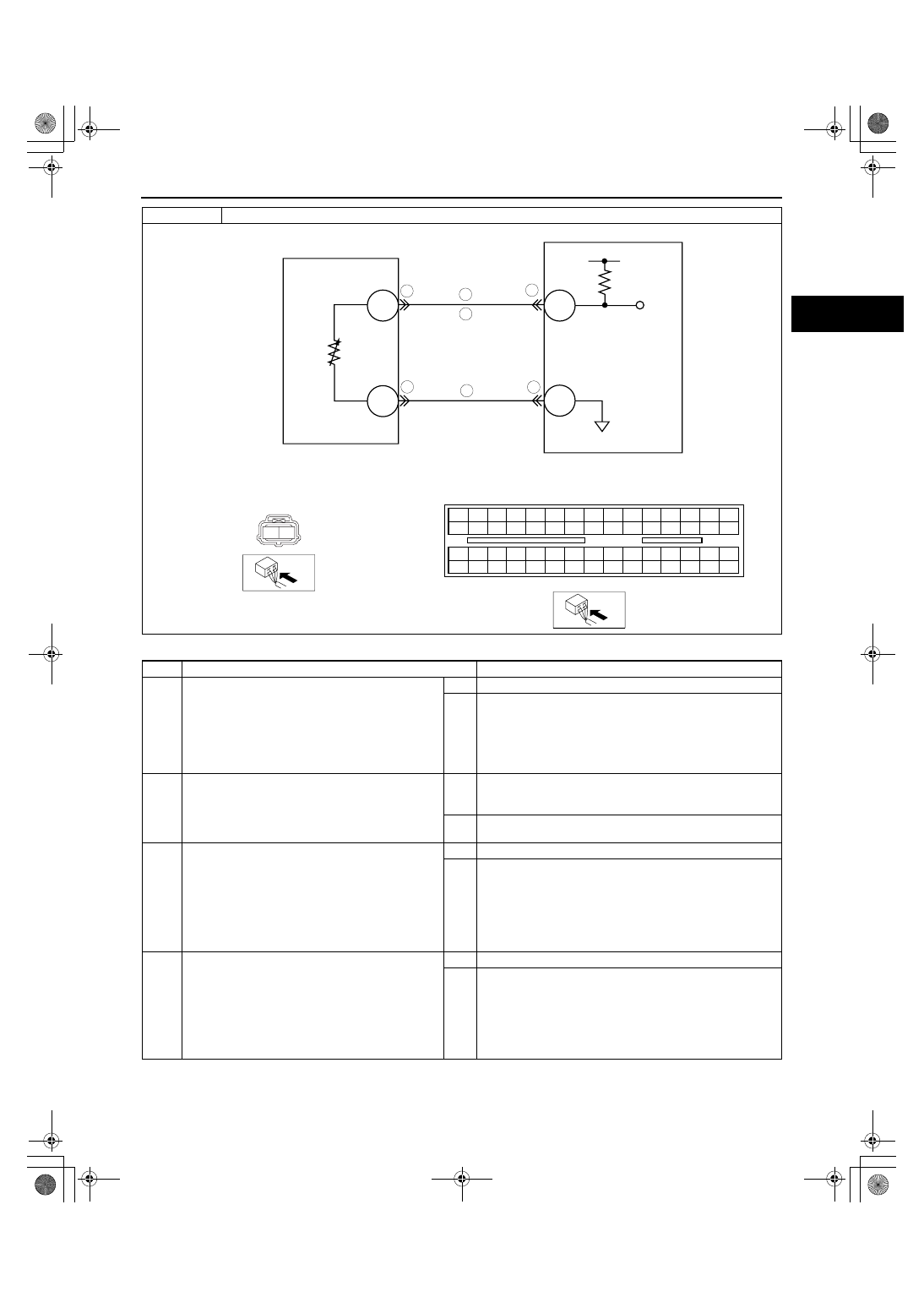

DTC P0118

ECT sensor circuit high input

ECT SENSOR

A

B

2AH

2AY

PCM

PCM

WIRING HARNESS-SIDE CONNECTOR

ECT SENSOR

WIRING HARNESS-SIDE CONNECTOR

A

B

3

5

6

6

8

3

7

2BE 2BA 2AW 2AS 2AO 2AK 2AG 2AC 2Y 2U 2Q 2M

2E

2A

2I

2BH 2BD 2AZ 2AV 2AR 2AN 2AJ 2AF 2AB 2X 2T 2P

2H

2D

2L

2BG 2BC 2AY 2AU 2AQ 2AM 2AI 2AE 2AA 2W 2S 2O

2G

2C

2K

2BF 2BB 2AX 2AT 2AP 2AL 2AH 2AD 2Z

2V 2R 2N

2F

2B

2J

1871-1U-06B(01-02).fm 67 ページ 2006年3月15日 水曜日 午前10時32分