Mazda CX 7. Manual - part 21

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–39

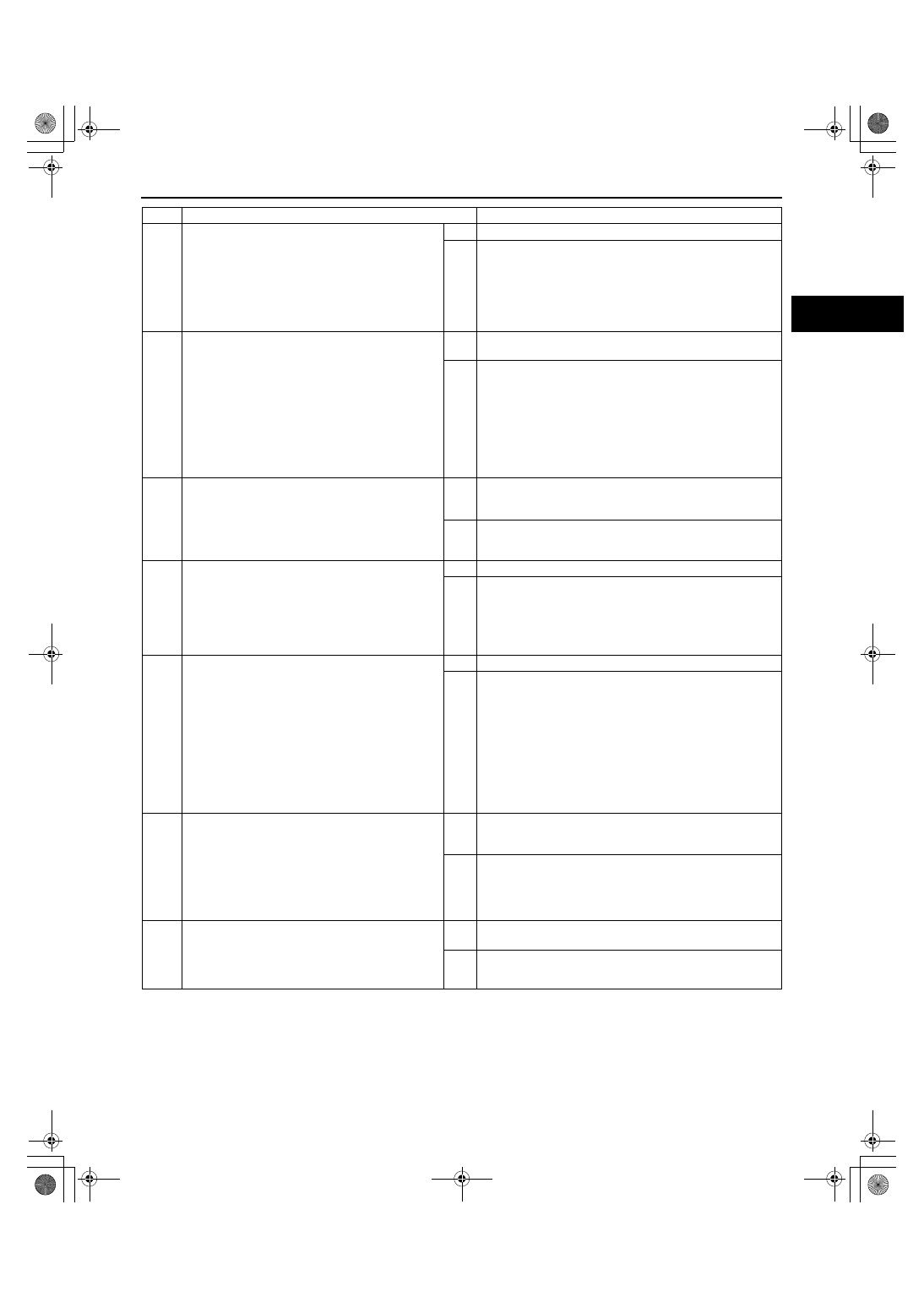

01-02

End Of Sie

3

INSPECT HIGH PRESSURE FUEL PUMP

CONNECTOR FOR POOR CONNECTION

• Turn the ignition switch off.

• Disconnect the high pressure fuel pump

connector.

• Inspect for poor connection (such as damaged/

pulled-out pins, corrosion).

• Is there any malfunction?

Yes

Repair or replace the terminal, then go to Step 8.

No

Go to the next step.

4

INSPECT SPILL VALVE CONTROL SOLENOID

VALVE CONTROL CIRCUIT FOR SHORT TO

GROUND

• Turn the ignition switch off.

• Inspect for continuity between the following

terminals:

— High pressure fuel pump terminal A (wiring

harness-side) and body ground

— High pressure fuel pump terminal B (wiring

harness-side) and body ground

• Is there continuity?

Yes

Repair or replace the wiring harness for a possible short to

ground, then go to Step 8.

No

Go to the next step.

5

INSPECT SPILL VALVE CONTROL SOLENOID

VALVE

• Inspect the spill valve control solenoid valve.

(See01-14-19 HIGH PRESSURE FUEL

PUMP INSPECTION[L3 WITH TC].)

• Is there any malfunction.

Yes

Replace the high pressure fuel pump, then go to Step 8.

(See01-14-16 HIGH PRESSURE FUEL PUMP REMOVAL/

INSTALLATION[L3 WITH TC].)

No

Go to the next step.

6

INSPECT PCM CONNECTOR FOR POOR

CONNECTION

• Turn the ignition switch off.

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/

pulled-out pins, corrosion).

• Is there any malfunction?

Yes

Repair or replace the terminal, then go to Step 8.

No

Go to the next step.

7

INSPECT SPILL VALVE CONTROL SOLENOID

VALVE CONTROL CIRCUIT FOR OPEN CIRCUIT

• Turn the ignition switch off.

• Inspect for continuity between the following

terminals:

— High pressure fuel pump terminal A (wiring

harness-side) and PCM terminal 2F (wiring

harness-side)

— High pressure fuel pump terminal B (wiring

harness-side) and PCM terminal 2G (wiring

harness-side)

• Is there continuity?

Yes

Go to the next step.

No

Repair or replace the wiring harness for a possible open

circuit, then go to the next step.

8

VERIFY TROUBLESHOOTING OF DTC P0091

COMPLETED

• Make sure to reconnect all the disconnected

connectors.

• Clear the DTC from the PCM memory using

the M-MDS.

• Start the engine.

• Is the same DTC present?

Yes

Replace the PCM, then go to the next step.

(See01-40-6 PCM REMOVAL/INSTALLATION[L3 WITH

TC].)

No

Go to the next step.

9

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

(See01-02-10 AFTER REPAIR

PROCEDURE[L3 WITH TC].)

• Are any DTCs present?

Yes

Go to the applicable DTC inspection.

(See01-02-13 DTC TABLE[L3 WITH TC].)

No

DTC troubleshooting completed.

STEP

INSPECTION

ACTION

1871-1U-06B(01-02).fm 39 ページ 2006年3月15日 水曜日 午前10時32分