Mazda 6. Manual - part 147

F–110

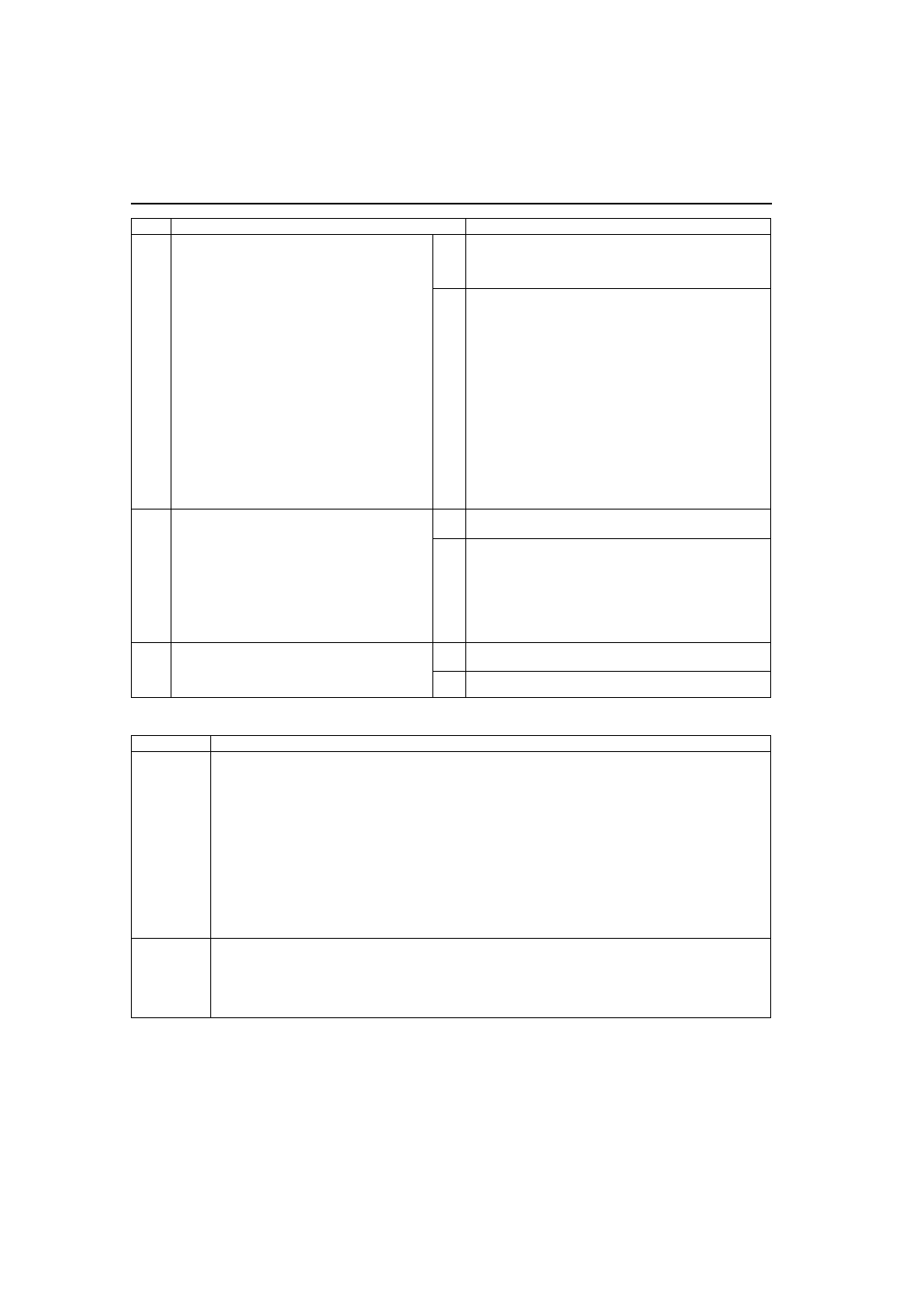

ON-BOARD DIAGNOSTIC

End Of Sie

DTC P0134

A6E397001084W24

12

INSPECT SEALING OF ENGINE COOLANT

PASSAGE

Warning

• Removing radiator cap when radiator is

hot is dangerous. Scalding coolant and

steam may shoot out and cause serious

injury.

• When removing radiator cap, wrap a

thick cloth around and turn it slowly.

• Remove radiator cap.

• Implement procedure to bleed air from engine

coolant, then run engine at idle.

• Is there any small bubble, which makes engine

coolant white at filling opening?

Note

• Large bubbles are normal since they are

remaining air coming out from engine

coolant passage.

Yes Air gets in from poor sealing on head gasket or other areas

between combustion chamber and engine coolant

passage.

Repair or replace faulty parts, then go to next step.

No

Go to next step.

13

VERIFY TROUBLESHOOTING OF DTC P0133

COMPLETED

• Make sure to reconnect all disconnected

connectors.

• Turn ignition switch to ON (Engine OFF)

• Clear DTC from memory using WDS or

equivalent generic OBD function.

• Run OBD drive mode.

• Is PENDING CODE the same as DTC

present?.

Yes Replace PCM, then go to next step.

(See

No

Go to next step.

14

VERIFY AFTER REPAIR PROCEDURE

• Perform “After Repair Procedure”.

• Is there any DTC present?

Yes Go to applicable DTC troubleshooting.

(See

.)

No

Troubleshooting completed.

STEP

INSPECTION

ACTION

DTC P0134

Front HO2S circuit no activity detected

DETECTION

CONDITION

• PCM monitors input voltage from front HO2S when the following conditions are met. If input voltage from

sensor never exceed 0.55 V for 83.2 s, PCM determines that sensor circuit is not activated.

MONITORING CONDITIONS

— HO2S, HO2S heater and TWC repair verification drive mode

— Following conditions are met

• Engine speed is above 1,500 rpm.

• Engine coolant temperature is above 80 °C {176 °F}.

Diagnostic support note

• This is a continuous monitor (CCM).

• MIL illuminates if PCM detects the above malfunction condition in two consecutive drive cycles or in one

drive cycle while the DTC for the same malfunction has been stored in the PCM.

• PENDING CODE is available if PCM detects the above malfunction condition during first drive cycle.

• FREEZE FRAME DATA is available.

• DTC is stored in the PCM memory.

POSSIBLE

CAUSE

• Front HO2S deterioration

• Front HO2S heater malfunction

• Leakage exhaust system

• Open or short to ground circuit between front HO2S terminal A and PCM terminal 1AB

• Insufficient compression

• Engine malfunction