Mazda Protege 5. Manual - part 225

ON-BOARD DIAGNOSTIC

05–02–28

DTC P0733

A3U050201030W14

Diagnostic procedure

DTC P0733

Gear 3 incorrect (Incorrect Gear Ratio Detected)

DETECTION

CONDITION

•

PCM monitors revolution ratio of forward clutch drum revolution to differential gear case revolution when

the following monitoring conditions are met. If revolution ratio is below 0.863 or above 1.249, PCM

determines that there is malfunction.

Monitoring condition:

— ATF temperature 20

°°°°

C {68

°°°°

F} or above.

— Driving in 3 GR in D range.

— Engine run.

— Turbine speed within 225—4,988 rpm.

— Differential gear case (output) revolution speed 35 rpm or above.

— Any of the following not generated: DTC P0500, P0705, P0706, P0710, P0715, P0751, P0752, P0753,

P0756, P0757, P0758, P0761, P0762, P0763, P0766, P0767, P0768, P0771, P0772, P0773.

Diagnostic support note:

•

This is a continuous monitor (CCM).

•

MIL does not illuminate.

•

O/D OFF indicator light flashes if PCM detects the above malfunction condition during first drive cycle.

•

FREEZE FRAME DATA is not available.

•

Pending code is not available.

•

DTC stored in the PCM memory.

POSSIBLE

CAUSE

•

ATF level low

•

Deteriorated ATF

•

Shift solenoids A or C stuck

•

Pressure control solenoid stuck

•

Line pressure low

•

3-4 clutch slipping

•

Forward clutch slipping

•

Control valve stuck (Bypass, TCC or 3-4 shift valve)

•

Oil pump

•

PCM malfunction

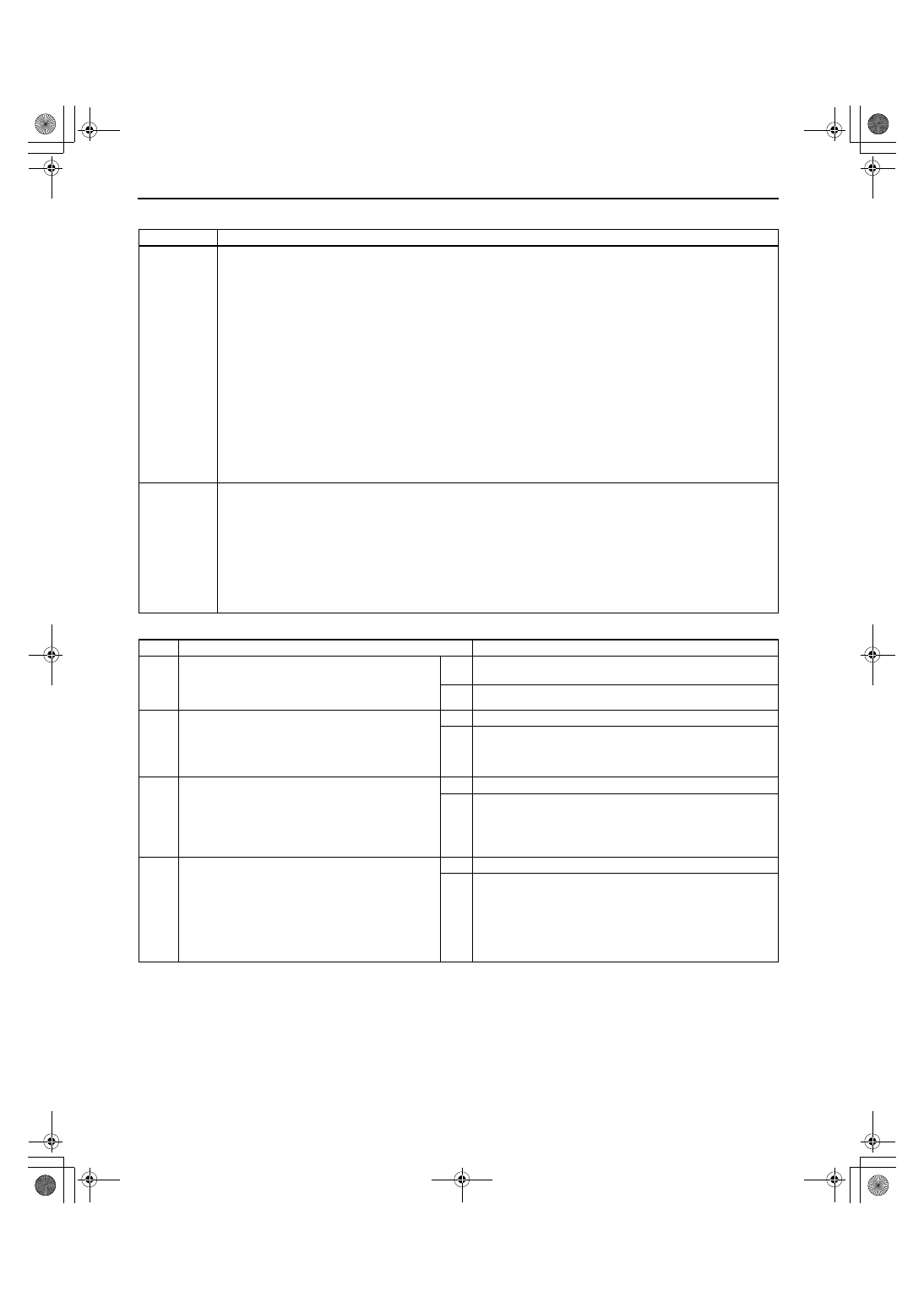

STEP

INSPECTION

ACTION

1

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•

Check for related Service Bulletins availability.

•

Is any related repair information available?

Yes Perform repair or diagnosis according to available repair

information.

No

Go to next step.

2

CHECK ATF CONDITION

•

Check ATF condition.

(See 05–17–17 AUTOMATIC TRANSAXLE

FLUID (ATF) INSPECTION.)

•

Is it okay?

Yes Go to next step.

No

Replace transaxle, then go to Step 8.

3

CHECK ATF LEVEL

•

Start engine.

•

Warm up ATX.

•

Is ATF level within specification?

(See 05–17–17 AUTOMATIC TRANSAXLE

FLUID (ATF) INSPECTION.)

Yes Go to next step.

No

Adjust ATF level, then go to Step 8.

4

INSPECTION SHIFT SOLENOID VALVE A AND

C FOR CLICK SOUND

•

Perform inspection of operation. (See 05–17–

28 SOLENOID VALVES INSPECTION.)

•

Verify the click sound of shift solenoid A and C

when applying B+ to each transaxle connector

terminal.

•

Was click heard from solenoids?

Yes Go to next step.

No

Replace solenoid that you could not hear click sound, then

go to Step 8.

(See 05–17–30 SOLENOID VALVES REMOVAL/

INSTALLATION.)

1712-1U-01G(05-02).fm 28 ページ 2001年6月29日 金曜日 午後4時35分