Mazda X-5. Manual - part 27

EMISSION SYSTEM

01–16–11

01–16

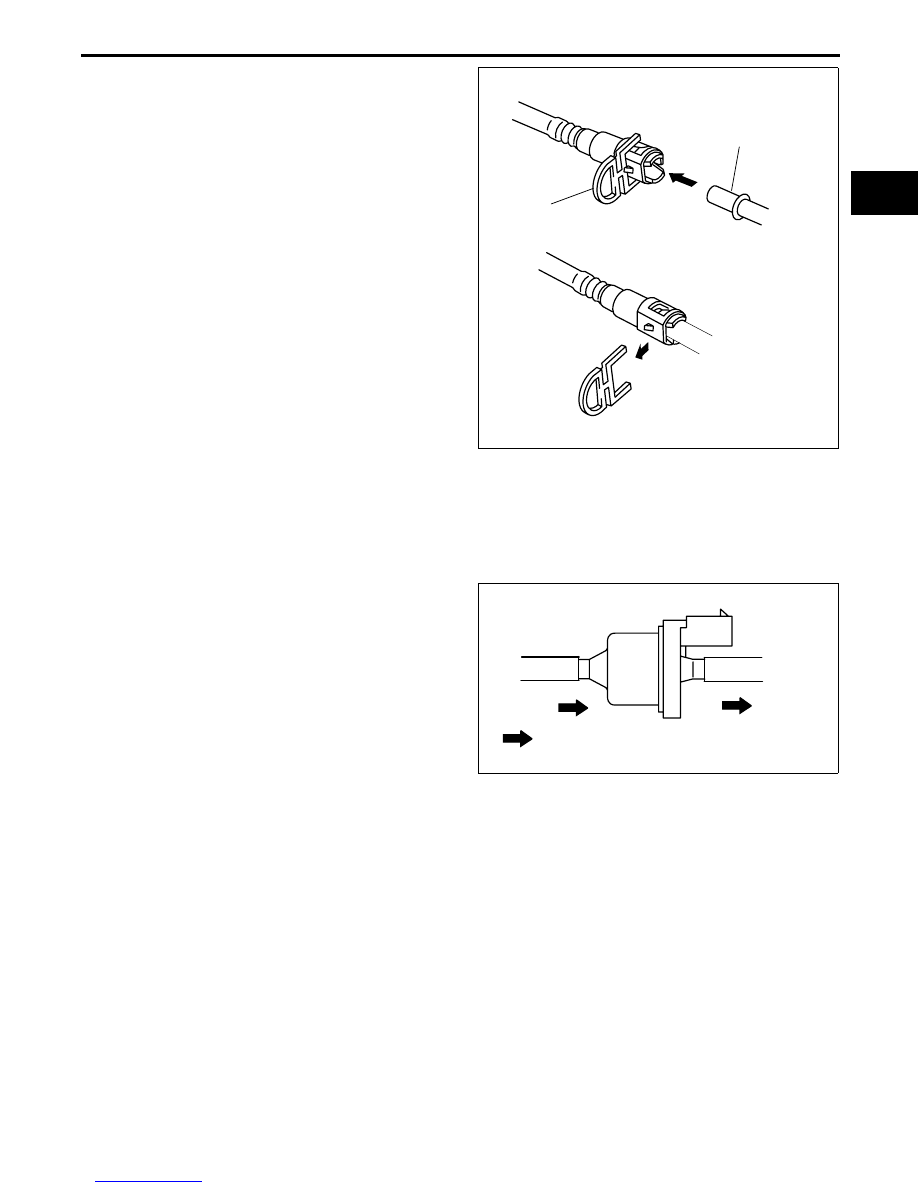

• New quick release connectors are fitted with a

checker tab that prevents improper fit. This

checker tab cannot normally be removed. When

the quick release connector is properly connected

to the connection point, the lock is released and

the checker tab comes off. Due to this, it can be

verified that the quick release connector is

completely connected.

End Of Sie

PURGE SOLENOID VALVE FUNCTION [LF]

E5U011618744N01

• Adjusts the amount of evaporative gas to be introduced to the intake air system.

End Of Sie

PURGE SOLENOID VALVE CONSTRUCTION/OPERATION [LF]

E5U011618744N02

• Installed on the air hose.

• Consists of a coil, spring and plunger.

• Opens and closes the passage in the solenoid

valve according to the purge solenoid valve

control signal (duty signal) from the PCM to

control the amount of evaporative gas to be

introduced to the dynamic chamber according to

engine operation conditions.

• The signal sent from the PCM energizes the coil

and it becomes magnetized, pulling the plunger.

The passage between the ports opens when the

plunger is pulled, and evaporative gas is

introduced to the intake air system according to

intake manifold vacuum.

End Of Sie

CHECKER TAB

CONNECTION POINT

EPU113ZT4610

FROM CHARCOAL

CANISTER

TO DYNAMIC

CHAMBER

: FLOW OF EVAPORATIVE GAS

E5U116ZW5042