Isuzu Trooper (1998-2002 year). Manual - part 696

7A–76

AUTOMATIC TRANSMISSION (4L30–E)

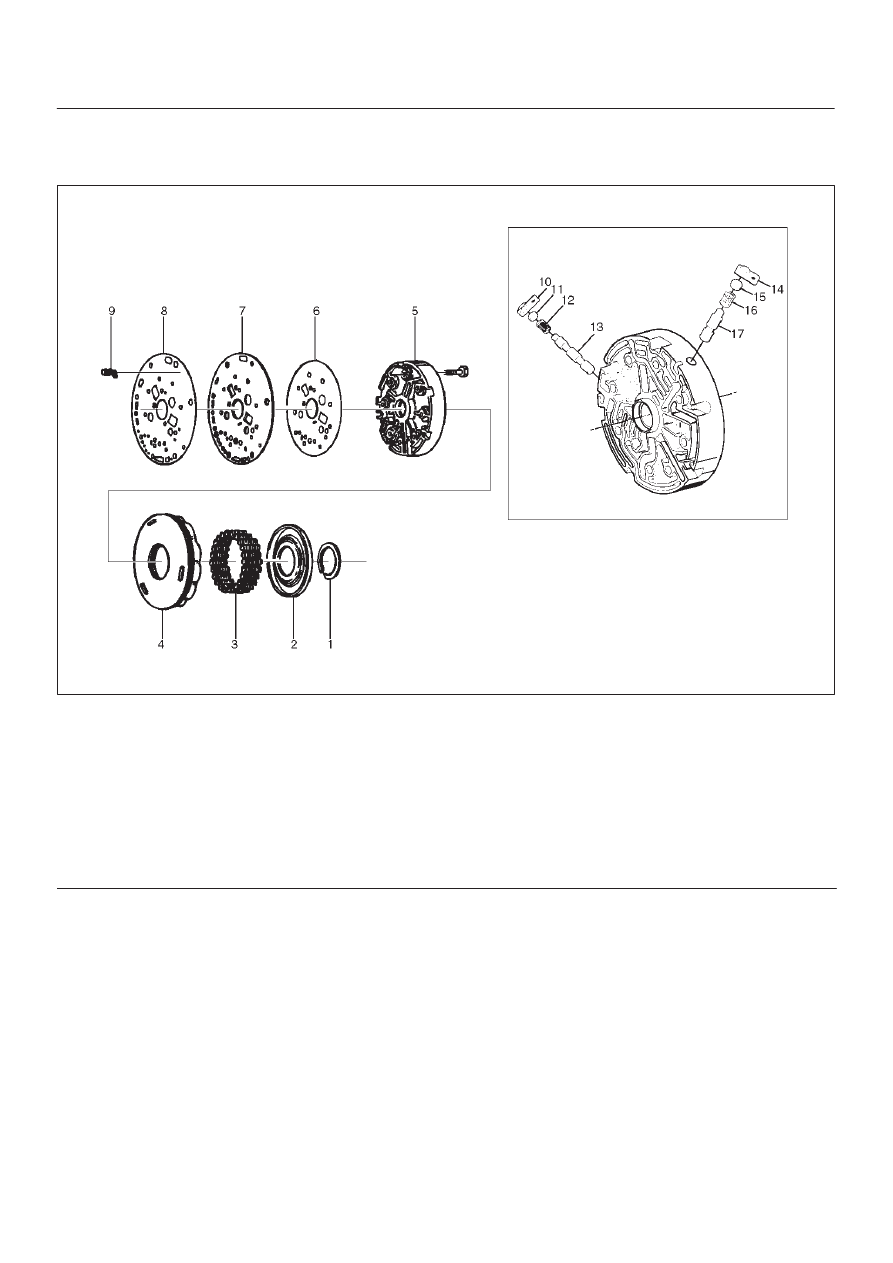

Reverse Clutch Piston And Center Support

Disassembled View

242RY001

Legend

(1) Retaining Ring

(2) Spring Seat

(3) Springs

(4) Piston Assembly

(5) Center Support

(6) Gasket

(7) Transfer Plate

(8) Gasket

(9) Restrictor

(10) Retainer Plate

(11) Plug

(12) Spring

(13) Overrun Lock Out Valve

(14) Retainer Plate

(15) Plug

(16) Spring

(17) Reverse Lock Out Control Valve