Isuzu Trooper (1998-2002 year). Manual - part 638

6E–200

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

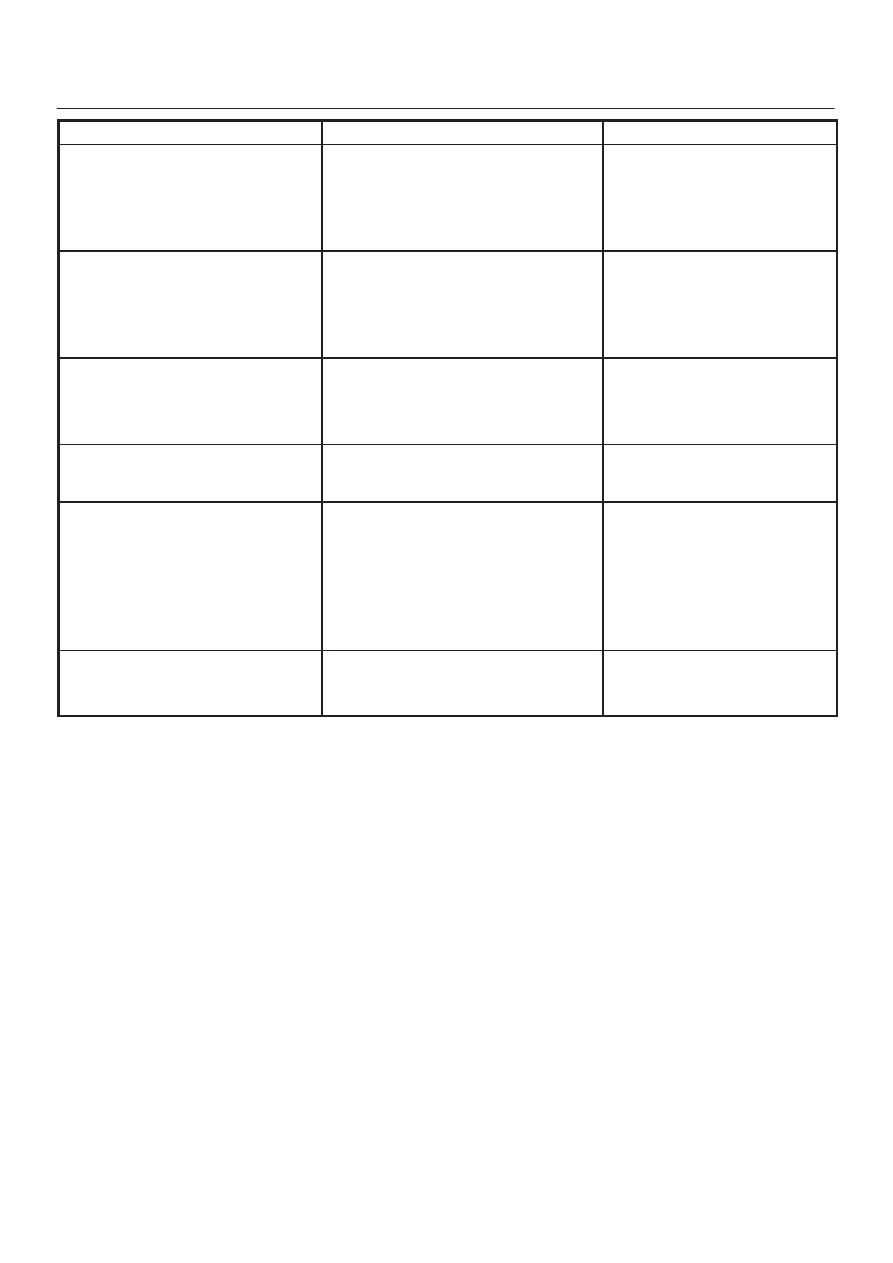

Symptoms

Initial Diagnosis

Default Section(s)

Hesitation, Sag, Stumble

1. OBD system check.

2. AP.

3. MAP output check.

4. Fuel system diagnosis.

5. Injector system.

Generator Output Voltage (refer

to

Chassis Electrical),

Calibration ID/Service Bulletins,

Ignition System Check

Rough, Unstable, or Incorrect Idle,

Stalling

1. OBD system check.

2. Fuel injector test.

MAP Output Check, Throttle

Linkage, A/C Clutch Control

Circuit Diagnosis, Calibration

ID/Service Bulletins, Generator

Output Voltage (refer to

Chassis

Electrical), Exhaust Diagnosis

Poor Fuel Economy

1. OBD system check.

2. Careful visual/physical inspection.

3. Injector system.

4. Cooling system.

TCC Operation, Exhaust

System (refer to

Engine

Exhaust)

Engine Cranks But Will Not Run

1. OBD system check.

Fuel System Electrical

Diagnosis, Fuel System

Diagnosis, Fuel Injector Test.

Excessive Exhaust Emissions or

Odors

1. OBD system check.

2. Emission test.

3. Cooling system.

4. Fuel system diagnosis.

5. Fuel injector test.

6. Injector system.

7. MAP output check.

Exhaust Diagnosis, Calibration

ID/Service Bulletins

Dieseling, Run-On

1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.

—