Isuzu Trooper (1998-2002 year). Manual - part 635

6E–188

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

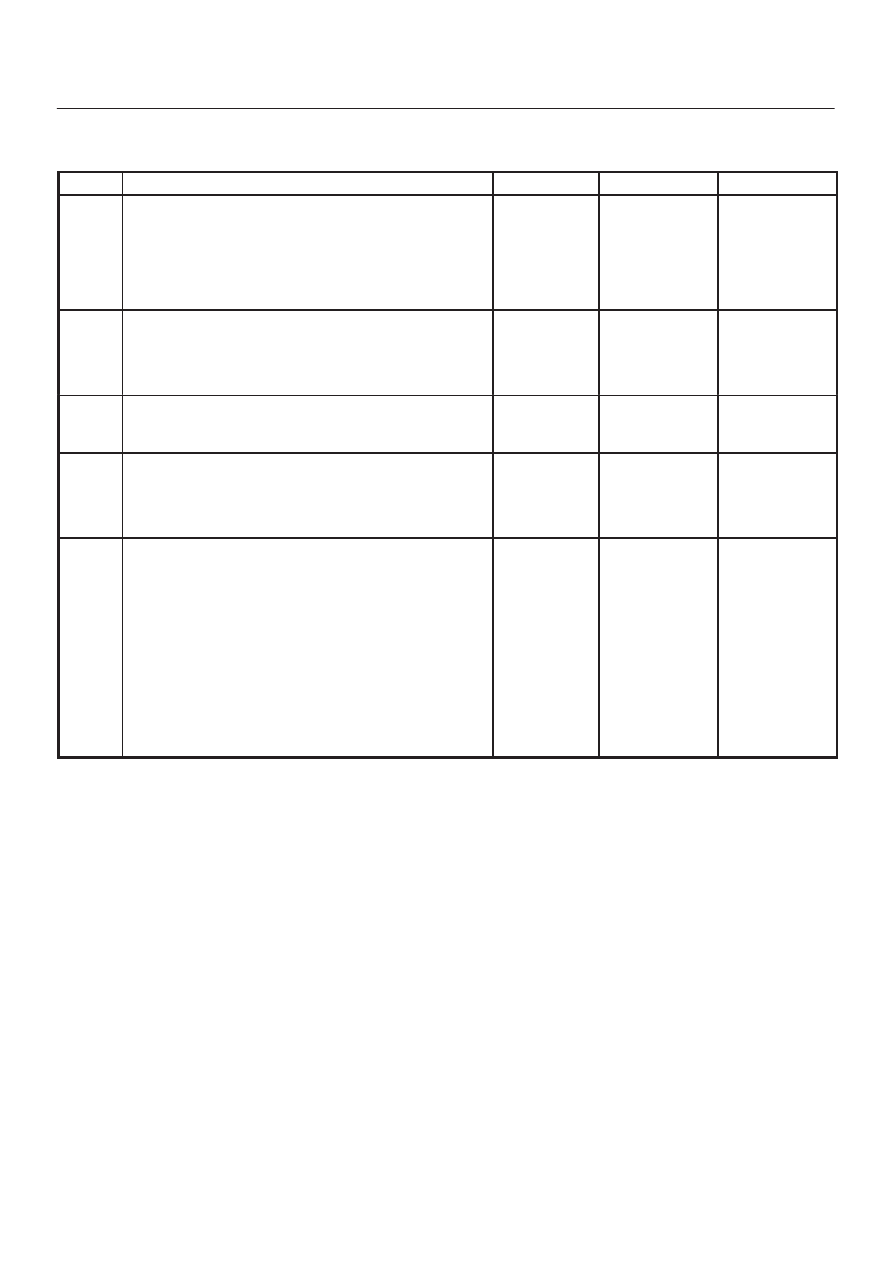

Dieseling, Run-On Symptom

Step

Action

Value(s)

Yes

No

1

DEFINITION:

Engine continues to run after key is turned “OFF,” but

runs very rough. If engine runs smooth, check ignition

switch and adjustment.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to

Step 3

3

Was a visual/physical check performed?

—

Go to

Step 4

Go to

Visual/

Physical

Check

4

1. Check for a short between B+ and any of the ignition

feed circuits.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 5

5

1. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

D

Visual/physical inspection

D

Tech 2 data

D

Freeze Frame data/Failure Records butter

D

All electrical connections within a suspected

circuit and/or system

3. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Contact

Technical

Assistance