Isuzu Trooper (1998-2002 year). Manual - part 556

6A – 32 ENGINE MECHANICAL

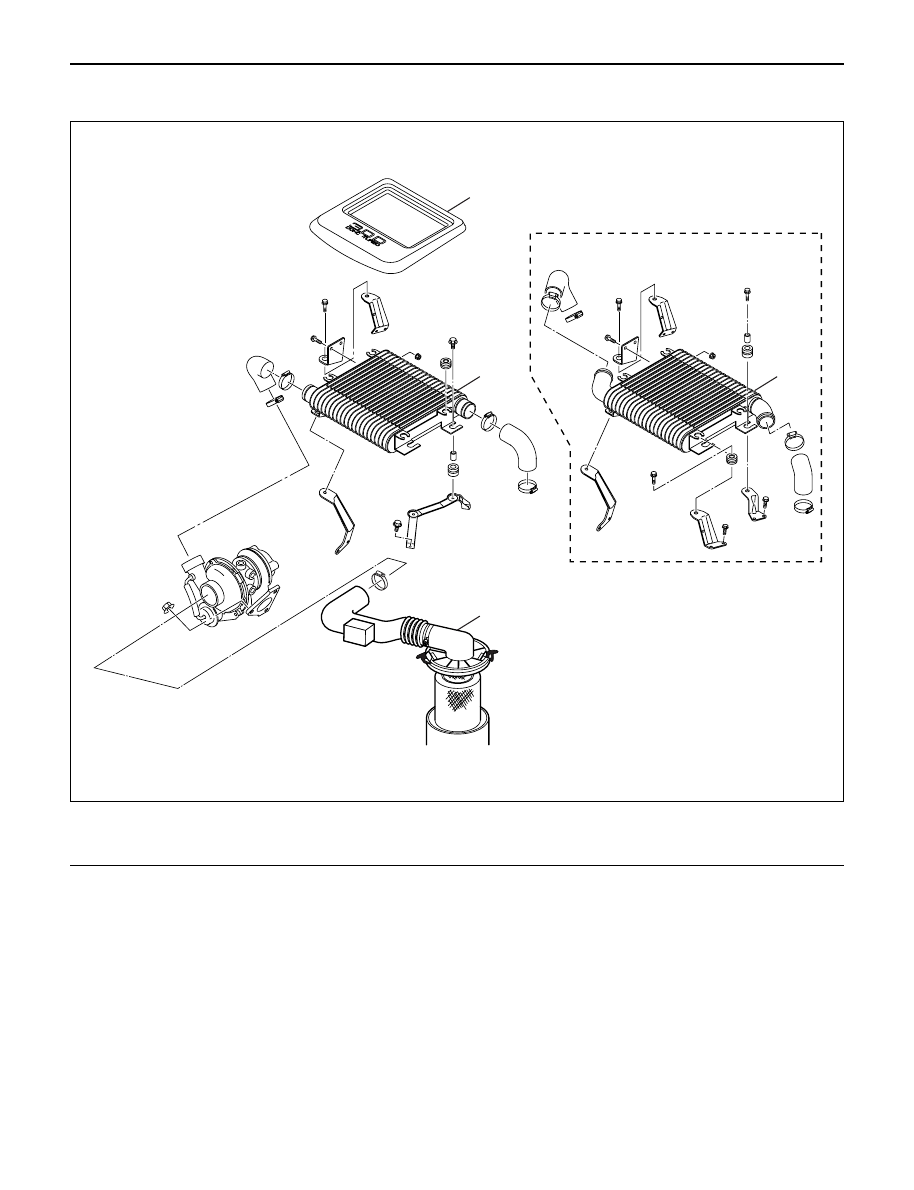

INTERCOOLER

REMOVAL

1. Disconnect the battery ground cable.

2. Remove air cleaner cover and air duct.

3. Remove intercooler cover.

4. Remove intercooler assembly.

1) Remove rubber hose from between intercooler

outlet and intake manifold inlet.

2) Remove rubber hose from between

turbocharger outlet and intercooler inlet.

3) Remove intercooler assembly fixing bolts from

the bracket, remove intercooler assembly.

INSTALLATION

1. Intercooler assembly

1) Connect outlet hose to intake manifold.

Torque : 4 N·m (0.4 kg·m/35 lb in)

2) Connect inlet hose from turbocharger to

intercooler.

Torque : 4 N·m (0.4 kg·m/35 lb in)

3) Install intercooler and tighten fixing bolts to the

specified torque.

Torque : 20 N·m (2.0 kg·m/14 lb ft)

2. Install intercooler cover.

3. Install air cleaner cover and air duct.

4. Connect the battery ground cable.

For Europe

2

3

3

1

135R200003

Legend

(1)

Air Cleaner Cover & Air Duct

(2)

Intercooler Cover

(3)

Intercooler Assembly