Isuzu Trooper (1998-2002 year). Manual - part 360

6E–353

ENGINE DRIVEABILITY AND EMISSIONS

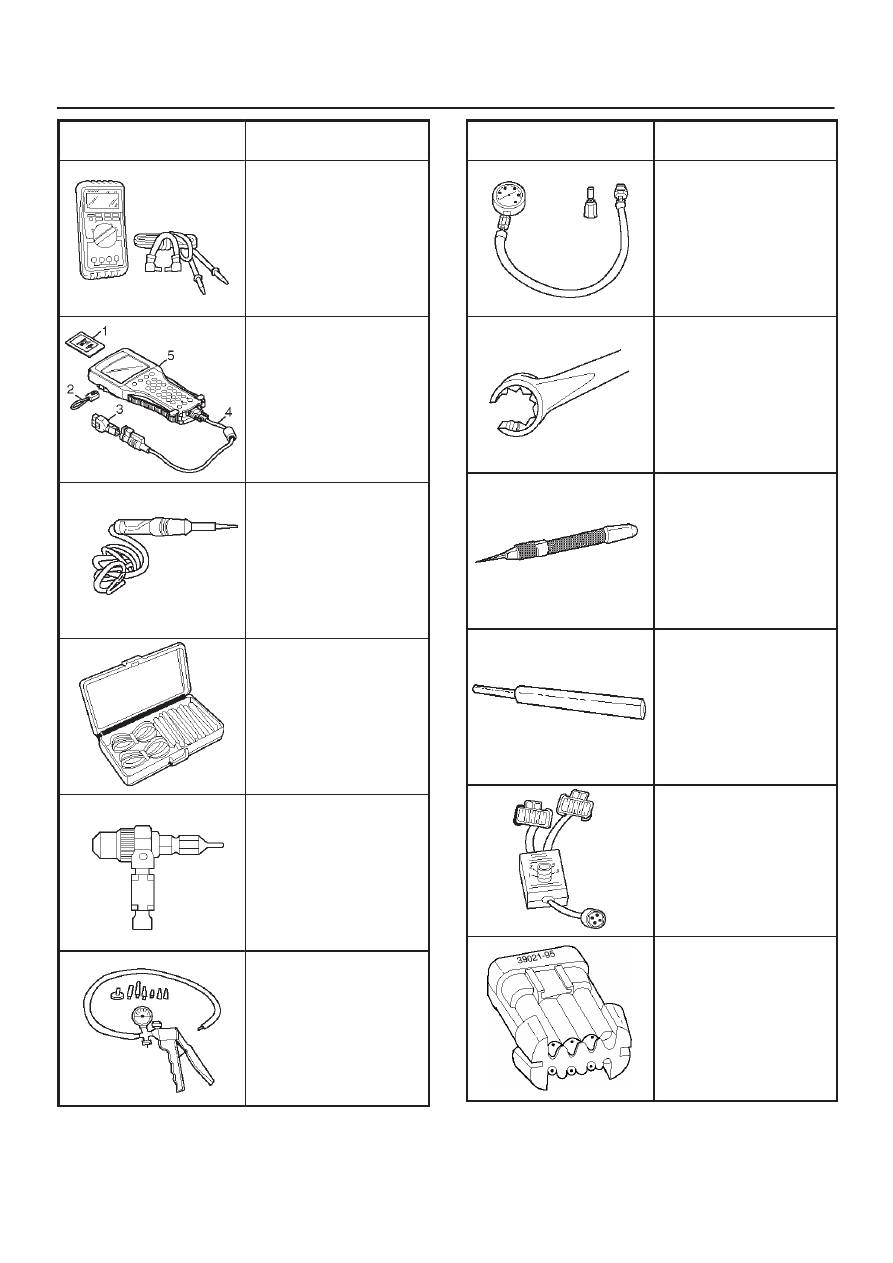

ILLUSTRATION

TOOL NO.

TOOL NAME

5-8840-0285-0

(J 39200)

High Impedance

Multimeter (Digital

Voltmeter – DVM)

(1) PCMCIA Card

(2) RS232 Loop Back

Connector

(3) SAE 16/19 Adapter

(4) DLC Cable

(5) TECH–2

5-8840-0607-0

(J 34142-B)

Unpowered Test Light

5-8840-0385-0

(J 35616-A/BT-8637)

Connector Test

Adapter Kit

5-8840-0383-0

(J 26792/BT-7220-1)

Spark Tester

5-8840-0279-0

(J 23738-A)

Vacuum Pump with

Gauge common tool

ILLUSTRATION

TOOL NO.

TOOL NAME

BT-8515

Exhaust Back Pressure

Tester or common tool

5-8840-2640-0

(J 39194-B)

Heated Oxygen Sensor

Wrench

5-8840-0632-0

(J 35689-A)

Terminal Remover

5-8840-0388-0

(J 28742-A)

Weather Pack II

Terminal Remover

5-8840-2635-0

(J 39021-90)

Injector Switch Box

5-8840-2636-0

(J 39021-65)

Injector Test Light