Isuzu Trooper (1998-2002 year). Manual - part 248

6A–66

ENGINE MECHANICAL

Limit : 0.12 mm (0.0047 mm)

014RW035

Reassembly

1. Install camshaft drive gear assembly and tighten

three bolts to specified torque.

Torque: 10 N·m (1.0 Kg·m/89 lb in)

2. Tighten sub gear setting bolt.

1. Use 5–8840–2443–0 to turn sub gear to right

direction until the M5 bolt hole aligns between

camshaft driven gear and sub gear.

2. Tighten M5 bolt suitable torque for prevent

moving the sub gear.

014RW041

3. Install camshaft assembly and camshaft brackets,

tighten twenty bolts on one side bank to the specified

torque.

1. Apply engine oil to camshaft journal and bearing

surface of camshaft bracket.

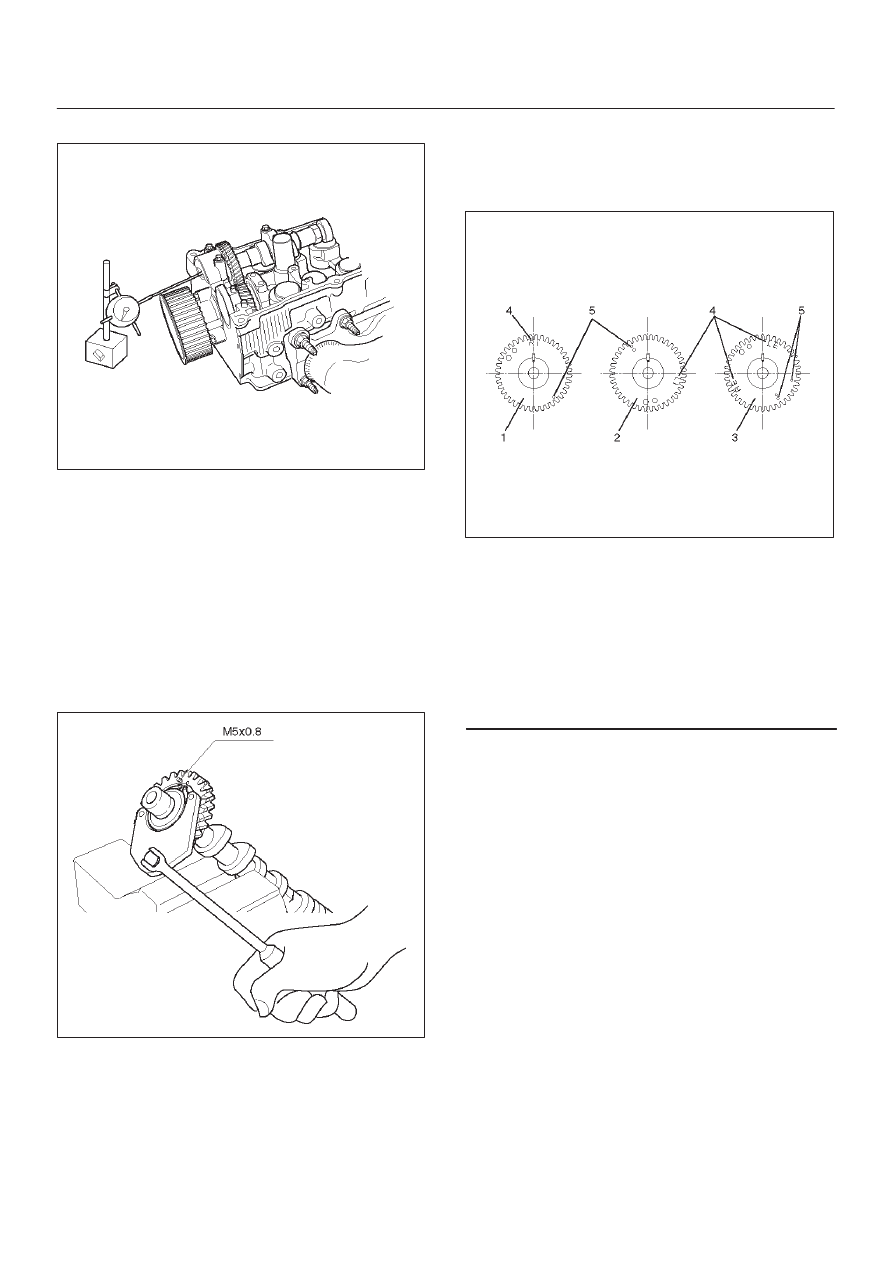

2. Align timing mark on intake camshaft (one dot for

right bank, two dots for left bank) and exhaust

camshaft (one dot for right bank, two dots for left

bank) to timing mark on camshaft drive gear (one

dot).

014RW020

Legend

(1) Intake Camshaft Timing Gear for Right Bank

(2) Intake Camshaft Timing Gear for Left Bank

(3) Exhaust Camshaft Timing Gear

(4) Discerning Mark

LI: Left Bank Intake

RI: Right Bank Intake

LE: Left Bank Exhaust

RE: Right Bank Exhaust