Isuzu Trooper (1998-2002 year). Manual - part 212

5B–6

ANTI–LOCK BRAKE SYSTEM

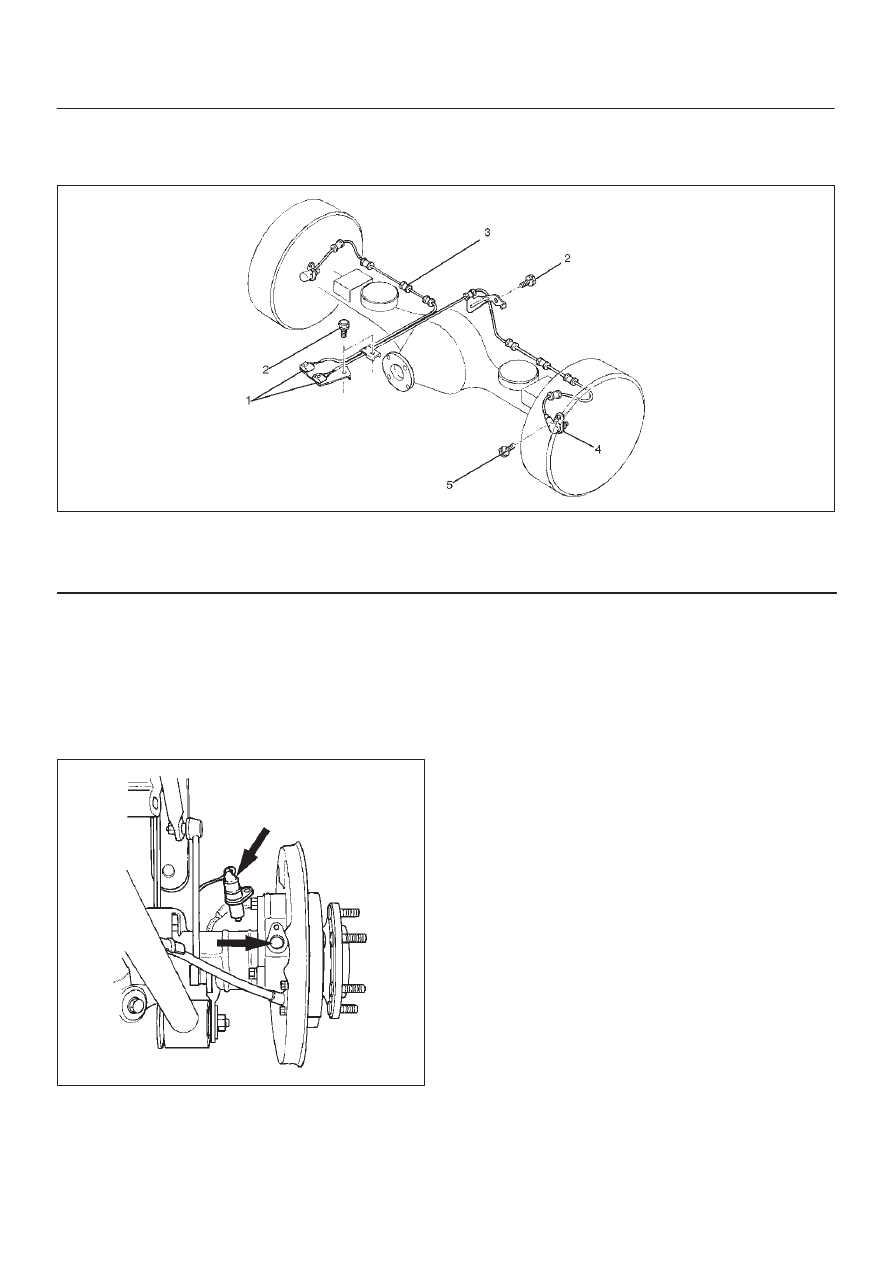

Rear Wheel Speed Sensor

Rear Wheel Speed Sensor and Associated Parts

350RW008

Legend

(1) Speed Sensor Connector

(2) Sensor Cable Fixing Bolt

(3) Clip (11 pieces)

(4) Speed Sensor

(5) Sensor Fixing Bolt

Removal

1. Remove speed sensor connector.

2. Remove clip.

3. Remove sensor cable fixing bolt.

4. Remove sensor fixing bolt.

5. Remove speed sensor.

350RS035

Inspection and Repair

1. Check the speed sensor pole piece for presence of

foreign materials; remove any dirt, etc.

2. Check the pole piece for damage, and replace the

speed sensor if necessary.

3. Check the speed sensor cable for a short or an open,

and replace with a new one if necessary. To check for

cable short or open, bend or stretch the cable while

checking for continuity.

4. Check the sensor ring for damage including tooth

chipping. If damaged replace the axle shaft assembly.

Refer to Front Hub and Disc in Drive Shaft System

section.

Installation

1. Install the speed sensor and take care not to hit the

speed sensor pole piece during installation.

2. Install the sensor fixing bolt and tighten it to the

specified torque.

Torque : 18 N·m (1.8kg·m/13 lb ft)

3. Install the sensor cable fixing bolt and tighten it to the

specified torque.

Torque : 24 N·m (2.4kg·m/18 lb ft)

NOTE: Confirm that the cable is not twisted when

connecting the speed sensor cable.

4. Install clip.

5. Install speed sensor connector.