Isuzu Trooper (2000 year). Manual - part 353

6E–541

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

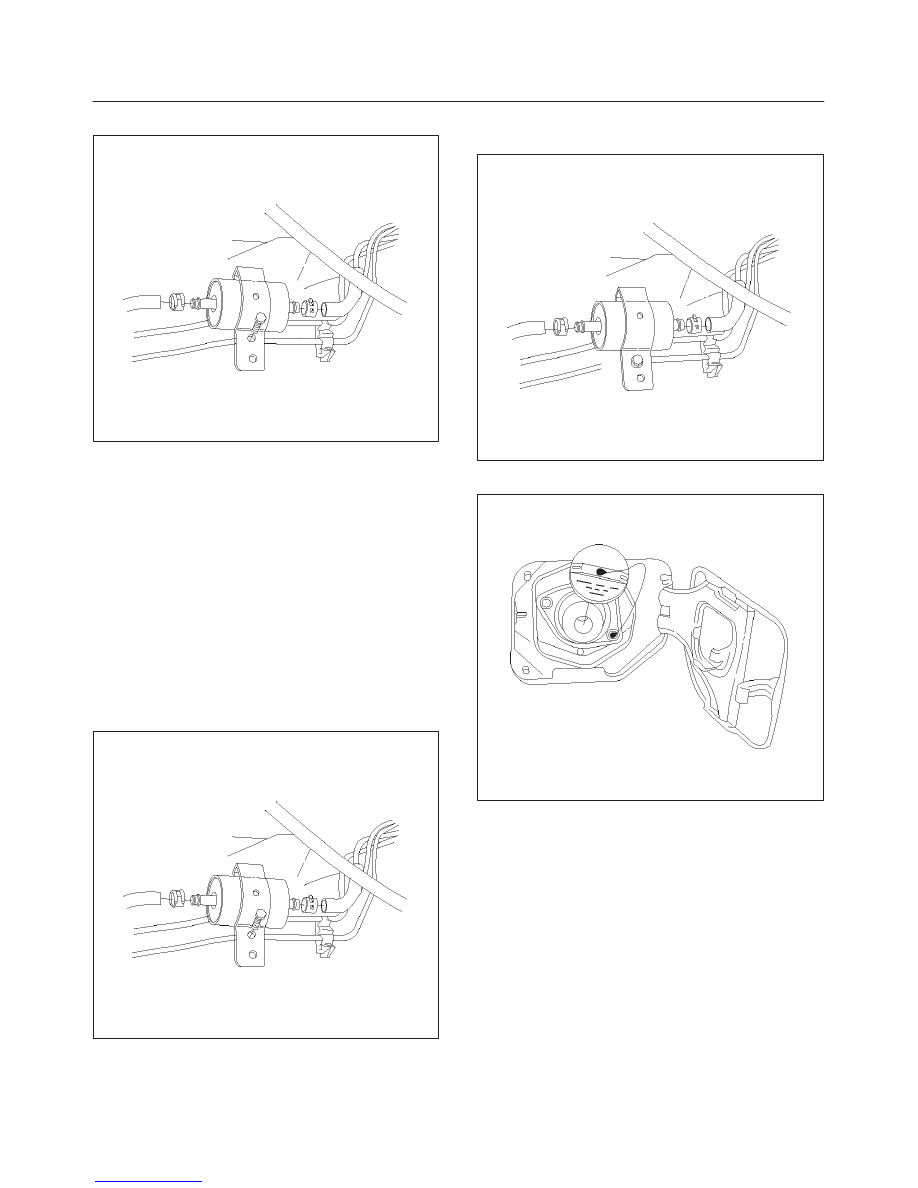

5. Remove the bolt on the fuel filter holder.

041RW007

6. Remove the fuel filter.

Inspection Procedure

1. Replace the fuel filter when the following occur:

D

Fuel leaks from the fuel filter body.

D

The fuel filter body is damaged.

D

The fuel filter is clogged with dirt or sediment.

Installation Procedure

1. Install the fuel filter in the correct direction.

2. Install the bolt on the fuel filter holder.

Tighten

D

Tighten the screws to 20 N·m (14 lb ft.).

041RW007

3. Connect the fuel line on the engine side.

4. Connect the fuel line on the fuel tank side.

041RW006

5. Install the fuel filler cap.

041RW005

6. Connect the negative battery cable.