Isuzu Trooper (2000 year). Manual - part 241

6E–93

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

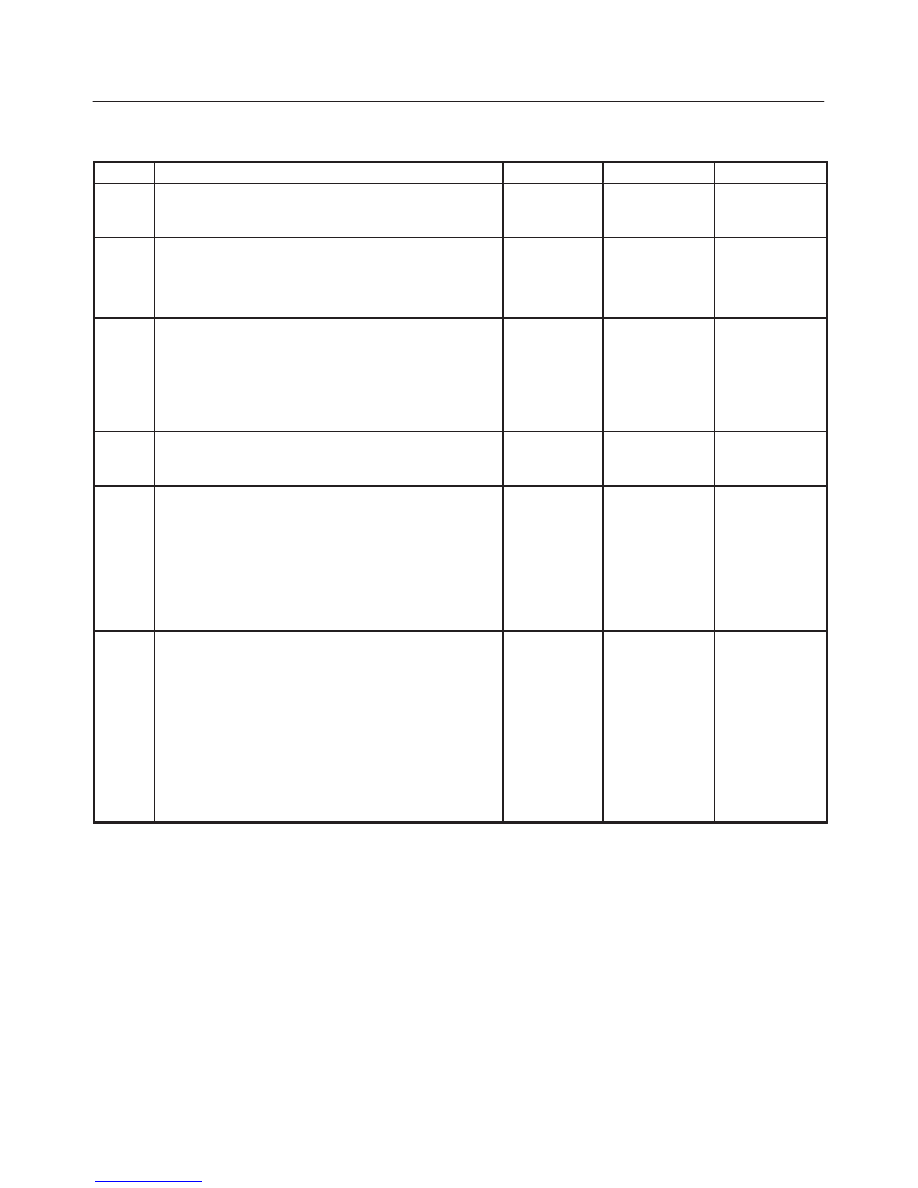

Malfunction Indicator Lamp (MIL) “ON” Steady

Step

Action

Value(s)

Yes

No

1

Was the “On-Board diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “OFF,” disconnect PCM.

2. Ignition “ON,” observe the MIL (Service Engine

Soon lamp).

Is the MIL “ON?”

—

Go to

Step 3

Go to

Step 5

3

1. Ignition “OFF,” disconnect the instrument panel

cluster.

2. Check the MIL driver circuit between the PCM and

the instrument panel cluster for a short to ground.

3. If a problem is found, repair as necessary.

Was the MIL driver circuit shorted to ground?

—

Go to

OBD

System

Check

Go to

Step 4

4

Replace the instrument panel cluster.

Is the action complete?

—

Go to

OBD

System

Check

—

5

1. Ignition “OFF,” reconnect the PCM.

2. Ignition “ON,” reprogram the EEPROM. Refer to

On-Vehicle Service in Powertrain Control Module

and Sensors for procedures.

3. Using the Tech 2 output controls function, select

MIL dash lamp control and command the MIL

“OFF.” (Refer to the Miscellaneous test)

Did the MIL turn “OFF?”

—

Go to

OBD

System

Check

Go to

Step 6

6

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to

On-Vehicle Service in

Powertrain Control Module and Sensors for

procedures.

And also refer to latest Service Bulletin.

Check to see if the Latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Go to

OBD

System

Check

—