Isuzu Trooper (2000 year). Manual - part 25

HEATING, VENTILATION AND AIR CONDITIONING (HVAC) 1A–69

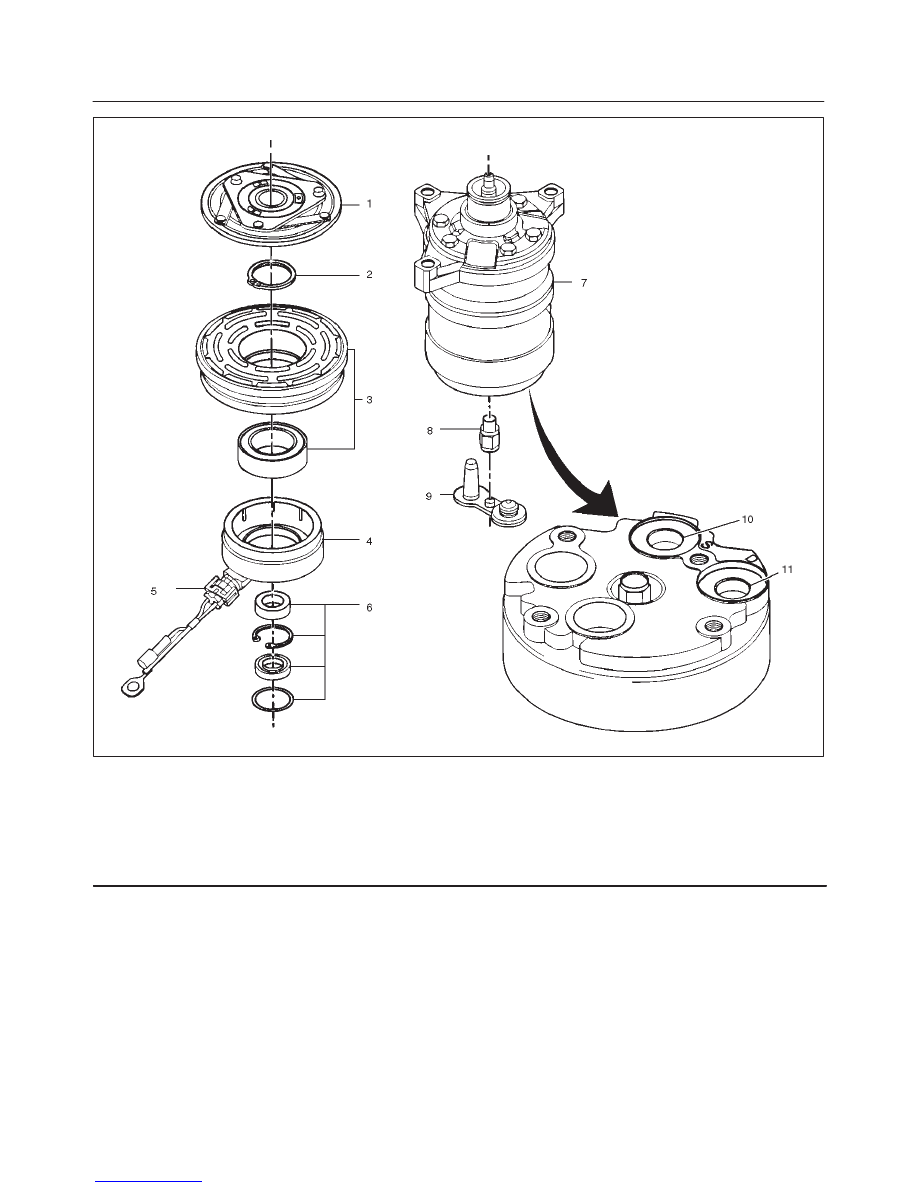

871RW002

Legend

(1) Clutch Driver

(2) Rotor Bearing Retainer

(3) Pulley Rotor and Bearing Assembly

(4) Clutch Coil Assembly

(5) Connector

(6) Shaft Seal Parts

(7) Pump Assembly

(8) High Pressure Relief Valve

(9) Shipping Cap

(10) Special 134a Suction Port

(11) Special 134a Discharge Port

The operations described below are based on bench

overhaul with the compressor removed from the vehicle,

except as noted. They have been prepared in order of

accessibility of the components. When a compressor is

removed from the vehicle for servicing, the amount of

PAG lubricant remaining in the compressor should be

drained, measured and recorded. This PAG lubricant

should then be discarded and an equal amount of new

PAG lubricant added to the compressor.

The service compressor is shipped without PAG oil.

When service procedures require, use only Isuzu

approved PAG oil.