Isuzu Trooper (2000 year). Manual - part 22

HEATING, VENTILATION AND AIR CONDITIONING (HVAC) 1A–57

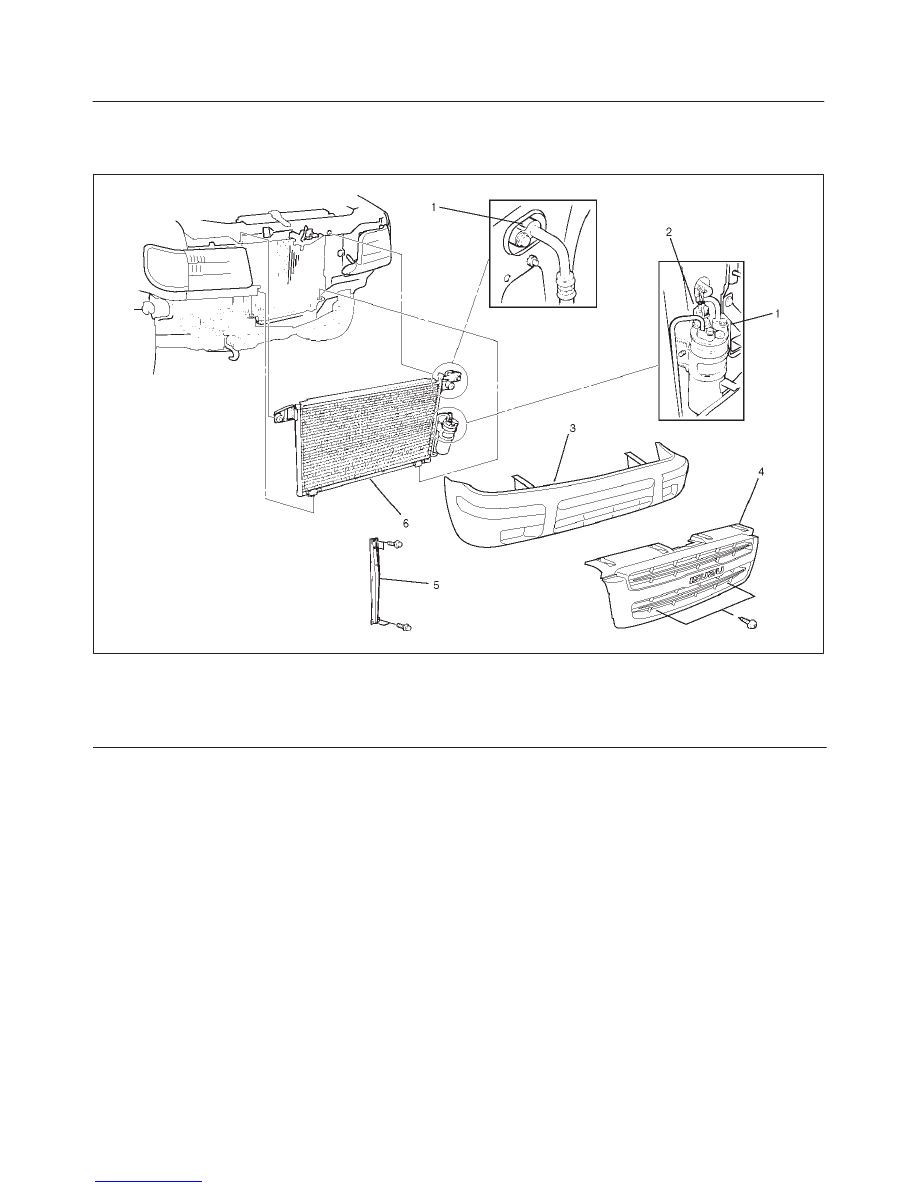

Condenser Assembly

Condenser Assembly and Associated Parts

875RY00005

Legend

(1) Refrigerant Line

(2) Pressure Switch Connector

(3) Front Bumper Assembly

(4) Radiator Grille

(5) Engine Hood Front End Stay

(6) Condenser Assembly

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

D

Refer to Refrigerant Recovery in this section.

3. Remove radiator grille.

4. Remove front bumper assembly.

D

Refer to Bumpers in Body and Accessories section.

5. Remove engine hood front end stay.

6. Disconnect pressure switch connector.

7. Disconnect refrigerant line.

D

When removing the line connector, the connecting

part should immediately be plugged or capped to

prevent foreign matter from being mixed into the

line.

8. Remove condenser assembly.

D

Handle with care to prevent damaging the

condenser or radiator fin.

Installation

1. Install condenser assembly.

D

If installing a new condenser, be sure to add 30cc

(1.0 fl. oz.) of new compressor oil to a new one.

D

Tighten the condenser fixing bolts to the specified

torque.

Torque: 6 N

•

m (52 lb

•

in)

2. Connect refrigerant line.

D

Tighten the inlet line connector fixing bolt to the

specified torque.

Torque: 15 N

•

m (11 lb

•

ft)

D

Tighten the outlet line connector fixing bolt to the

specified torque.

Torque: 6 N

•

m (52 lb

•

in)

D

O-rings cannot be reused. Always replace with new

ones.