Isuzu Rodeo UE. Manual - part 441

6F–6

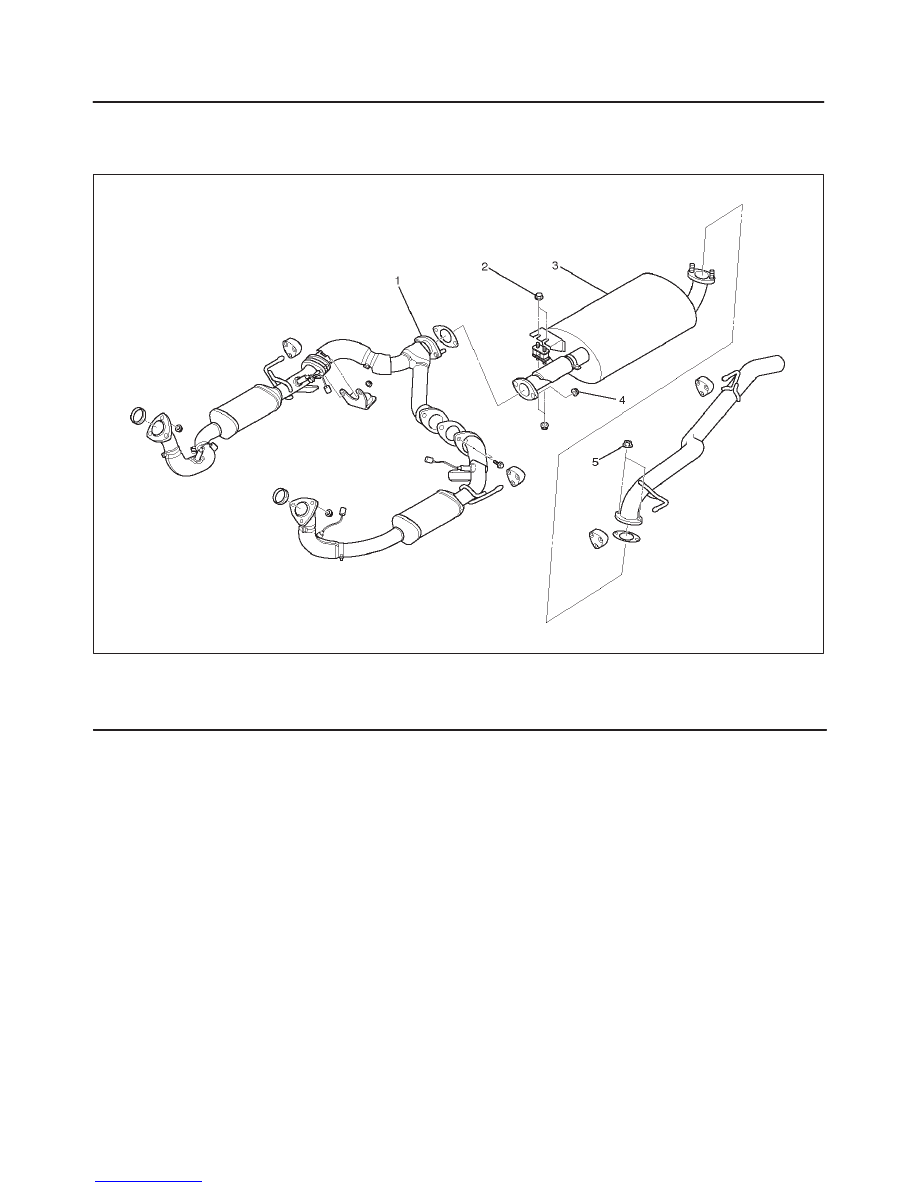

ENGINE EXHAUST (6VD1 3.2L)

Exhaust Silencer

Exhaust Silencer and Associated Parts

150RW027

Legend

(1) Forked Exhaust Pipe

(2) Support Rubber Fixing Nuts

(3) Exhaust Silencer

(4) Exhaust Silencer Fixing Nuts

(5) Rear Exhaust Pipe Fixing Nuts

Removal

1. Disconnect battery ground cable.

2. Lift up the vehicle and support with suitable safety

stands.

3. Remove the support rubber fixing nuts (2), the

exhaust silencer fixing nuts (4) and rear exhaust pipe

fixing nuts (5), then remove the exhaust silencer (3).

Installation

1. Install the exhaust silencer (3) and tighten the fixing

nuts (4) (5) to the specified torque.

Torque

Nuts: 43 N·m (32 lb ft)

2. Tighten the support rubber fixing nuts (2) to the

specified torque.

Torque

Bolts: 15 N·m (11 lb ft)