Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 666

7A1 – 164 AUTOMATIC TRANSMISSION (4L30-E)

23. Fourth Clutch Spring Retainer

1) Compress the fourth clutch spring retainer and

springs.

2) Release snap ring from groove.

3) Remove clutch compressor and snap ring.

4) Remove retainer and spring assembly.

Compressor: 5-8840-0195-0 (J-23327) and

5-8840-2263-0 (J-23327-90)

24. Fourth Clutch Piston

1) Insert two converter housing/main case screws to

hold adapter case while pulling out fourth clutch

piston.

2) Remove fourth clutch piston assembly.

3) Remove converter housing/main case screws.

25. Second and Third Clutch Assemblies

1) Grasp intermediate shaft, twist and pull out the

second and third clutch drum assemblies with

reverse clutch plates while holding onto output

shaft.

2) Separate 2nd and 3rd clutch assemblies.

3) Remove thrust washer.

4) Remove reverse clutch plates and reverse clutch

pressure plate.

26. Planetary Carrier Assembly

1) Remove bearing and washer.

2) Remove planetary carrier assembly.

3) Remove thrust bearing.

27. Reaction Sun Gear

1) Remove reaction sun gear

2) Remove needle bearing.

28. Brake Drum

Remove brake drum.

29. Brake Band

1) Remove brake band.

2) Remove thrust bearing.

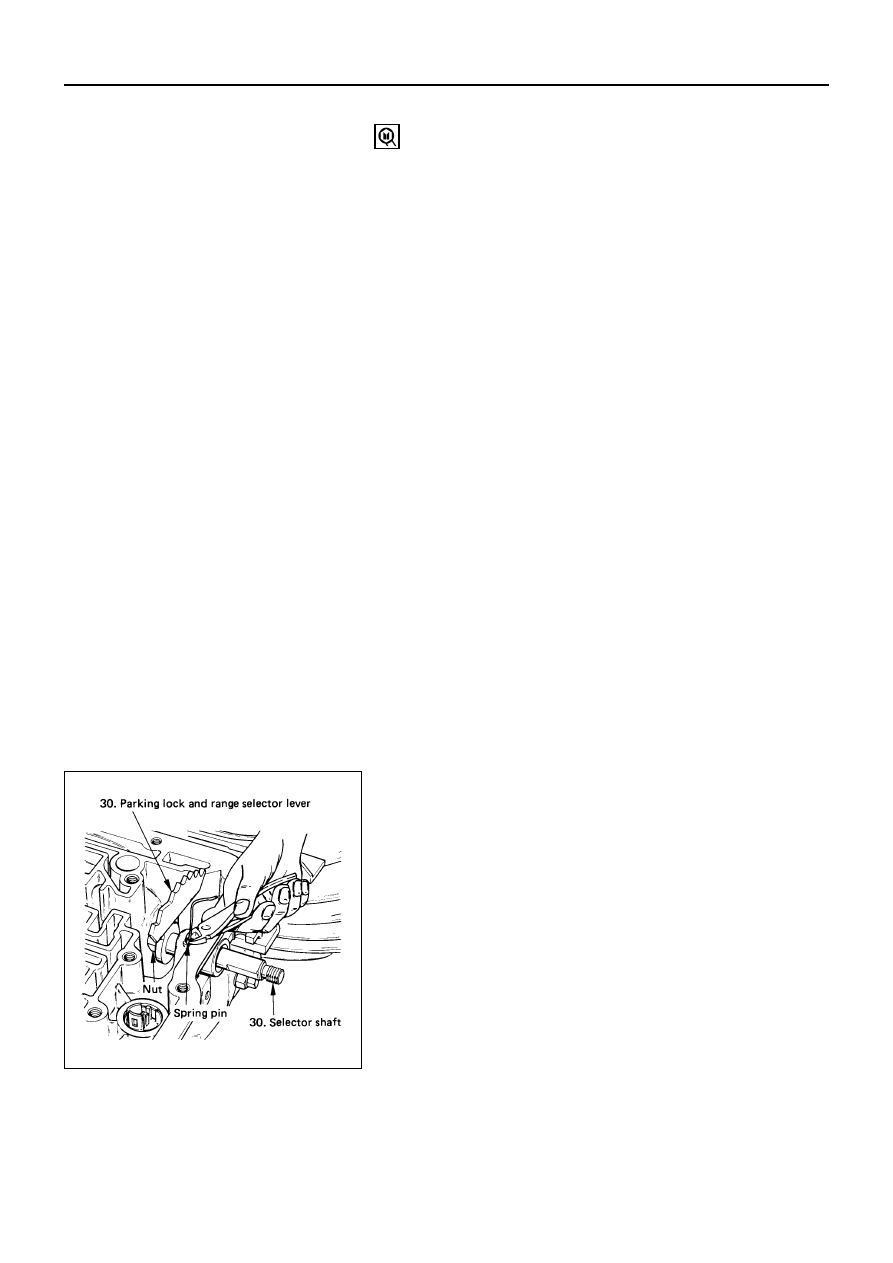

30. Parking Lock and Selector Lever Assembly

1) Rotate case to horizontal position, valve body side

facing up.

2) Remove spring pin, using cutting pliers.

NOTE:

Insert wire in the center of the spring pin to prevent

it from collapsing during removal. Be aware of pin

height. Protect machined face of main case.

3) Remove parking lock and range selector lever 17

mm nut.

4) Remove parking lock and range selector lever and

actuator assembly.

5) Remove selector shaft.

NOTE:

Inspect the shaft for burrs before removing to

prevent damaging seal. If necessary, remove burrs by

lightly sanding with an oilstone.